Flexible riveting equipment for automobile safety belt support

A seat belt bracket and riveting technology, which is applied in metal processing equipment, vehicle parts, forming tools, etc., can solve the problems of complex mold structure, high investment cost, and inflexible production, so as to reduce production costs, improve production efficiency, The effect of a short development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

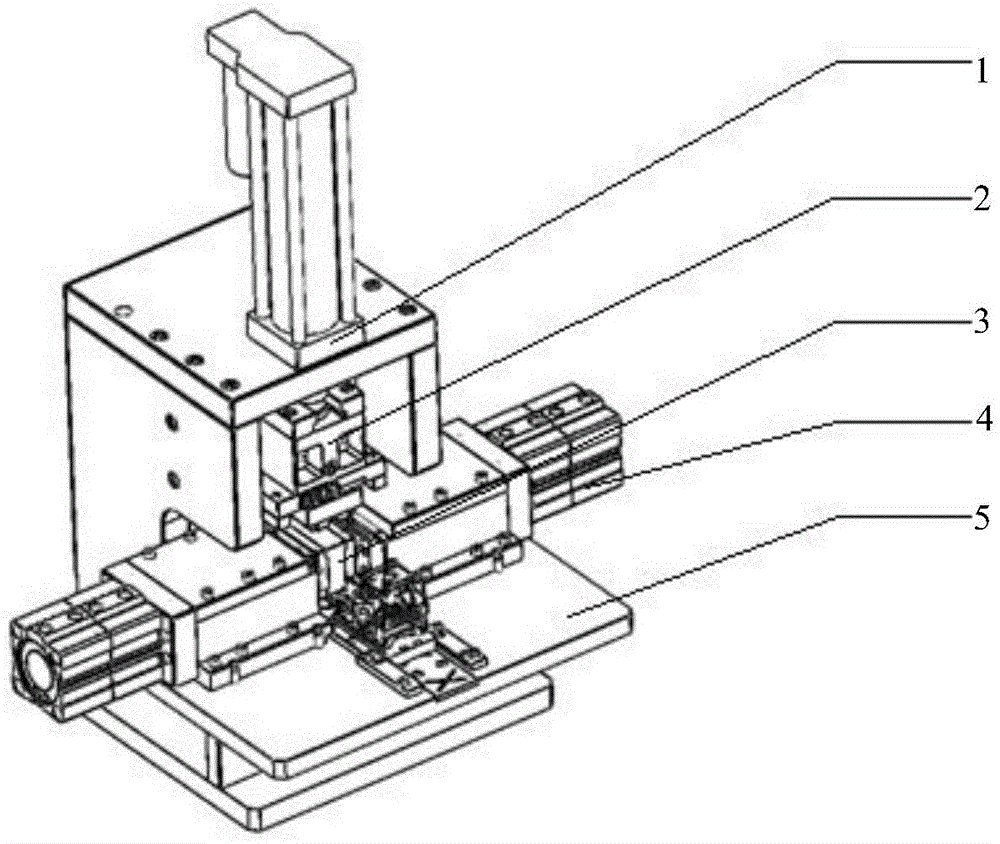

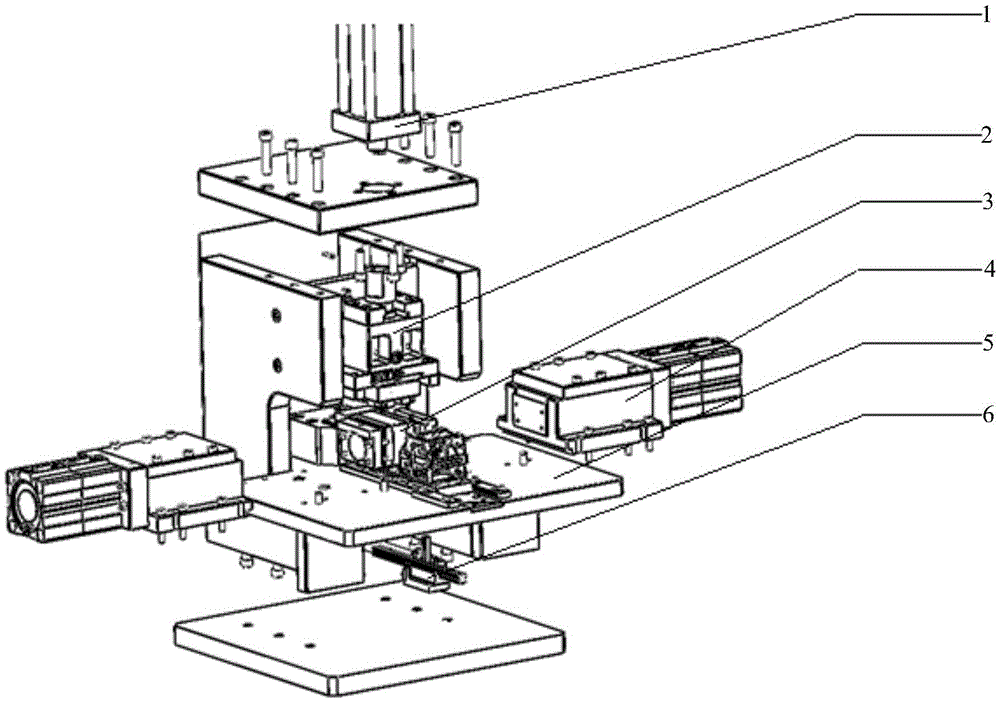

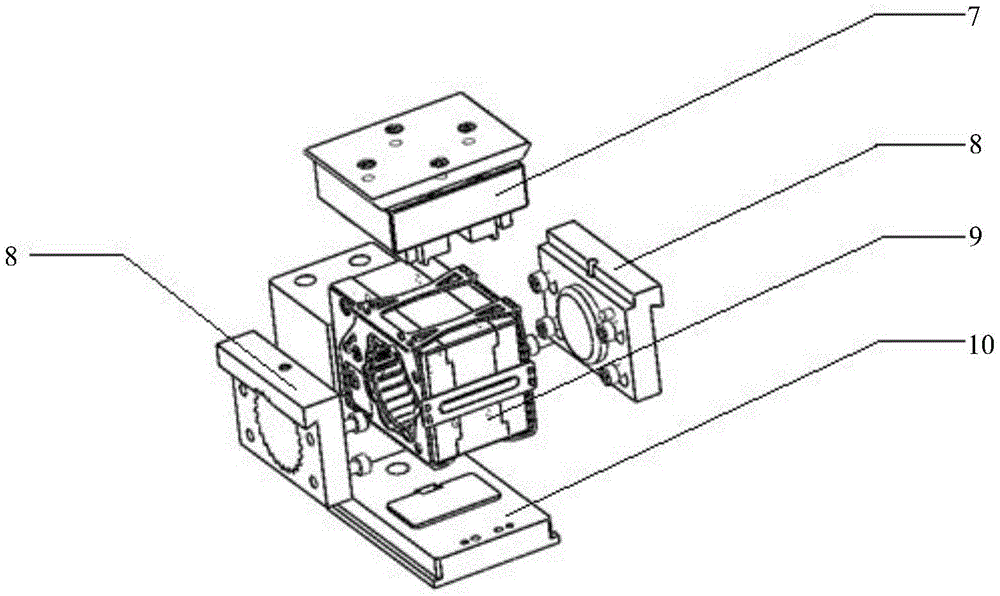

[0033] as attached Figure 1-2 The flexible riveting equipment for automobile seat belt bracket shown includes gas-hydraulic booster cylinder 1, riveting jig 3, conveying bracket sliding plate mechanism 6, riveting upper mold sliding block 2, seat belt bracket pressing block pressing mechanism 4 and riveting table 5. The riveting jig is located above the riveting table, and the sliding plate mechanism of the conveying bracket is located below the riveting table. There is a safety belt bracket pressing block pressing mechanism on both sides of the riveting jig, and the sliding block of the riveting upper die is located above the riveting jig. The hydraulic booster cylinder is located on the top of the flexible riveting equipment for the car s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com