Method for adding scaling powder into solder

A flux and solder technology, applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., can solve problems such as troublesome environments, unstable flux changes, and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

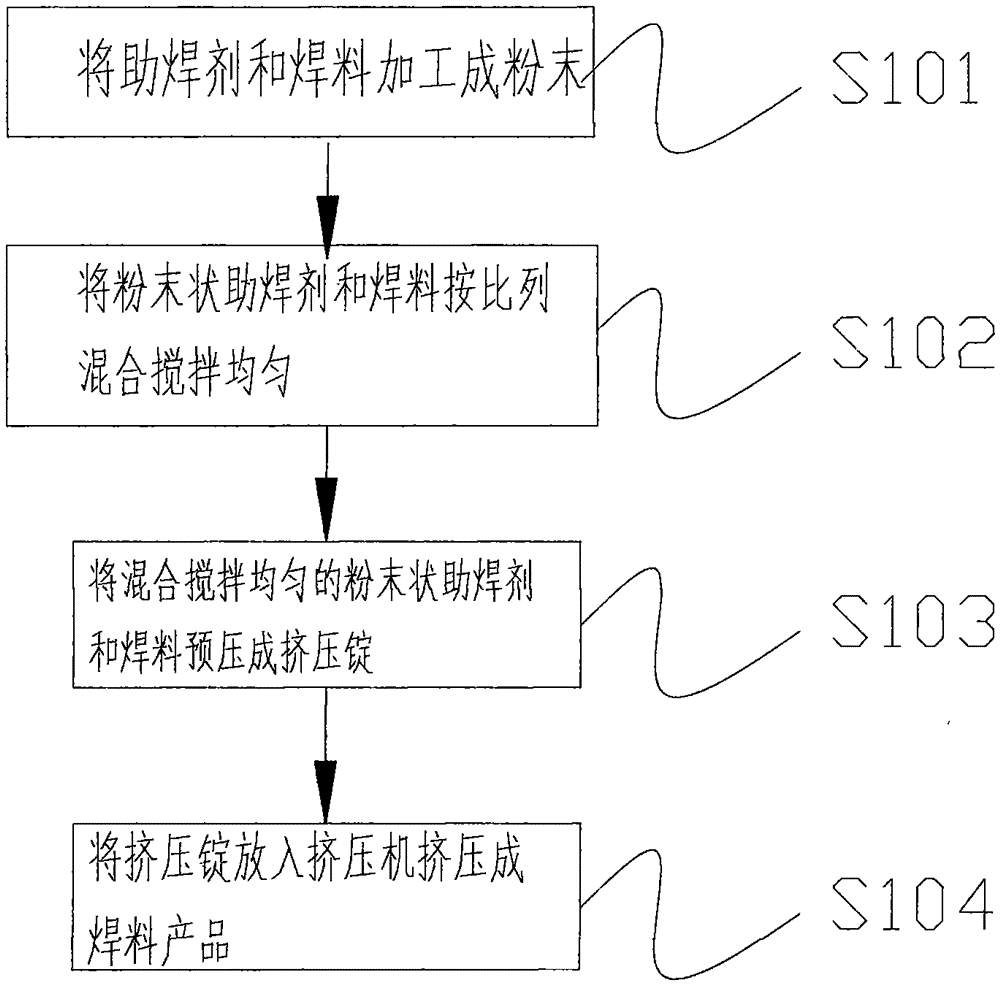

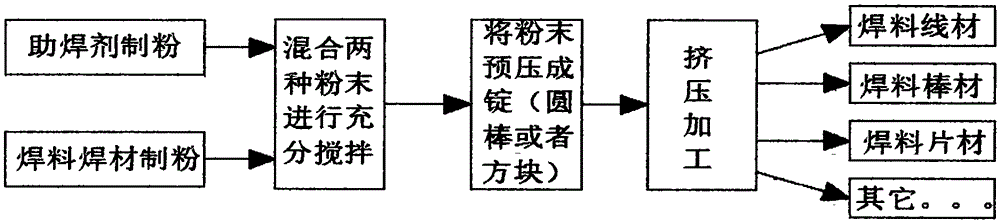

[0017] Step S101, first process the flux and solder into powder to obtain powdered flux and solder;

[0018] Step S102, then mix and stir the powdered flux and solder evenly in proportion;

[0019] Step S103, pre-pressing the uniformly mixed powdered flux and solder into an extruded ingot;

[0020] Step S104, finally putting the extruded ingot into an extruder to extrude into a solder product.

[0021] The specific implementation steps are as follows: firstly adjust the flux to the required formulation requirements, put it into a rolling machine at room temperature to process into fine powder, and then sieve the powder. Solder welding consumables are processed into powder by powder making equipment and sieved. The two powders were weighed according to the proportion and then mixed together, put into the drum mixer and stirred evenly. After stirring, put it into a vertical hydraulic press to pre-press into ingots, and pre-press into bars or round ingots as needed. The ingot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com