Water pressure type hydraulic machine

A hydraulic machine and hydraulic technology, applied in the direction of reaction engines, hydroelectric power generation, mechanical equipment, etc., can solve the problems of low utilization rate of water resources, achieve the goal of improving water energy utilization rate, reducing running resistance, and increasing output torque Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

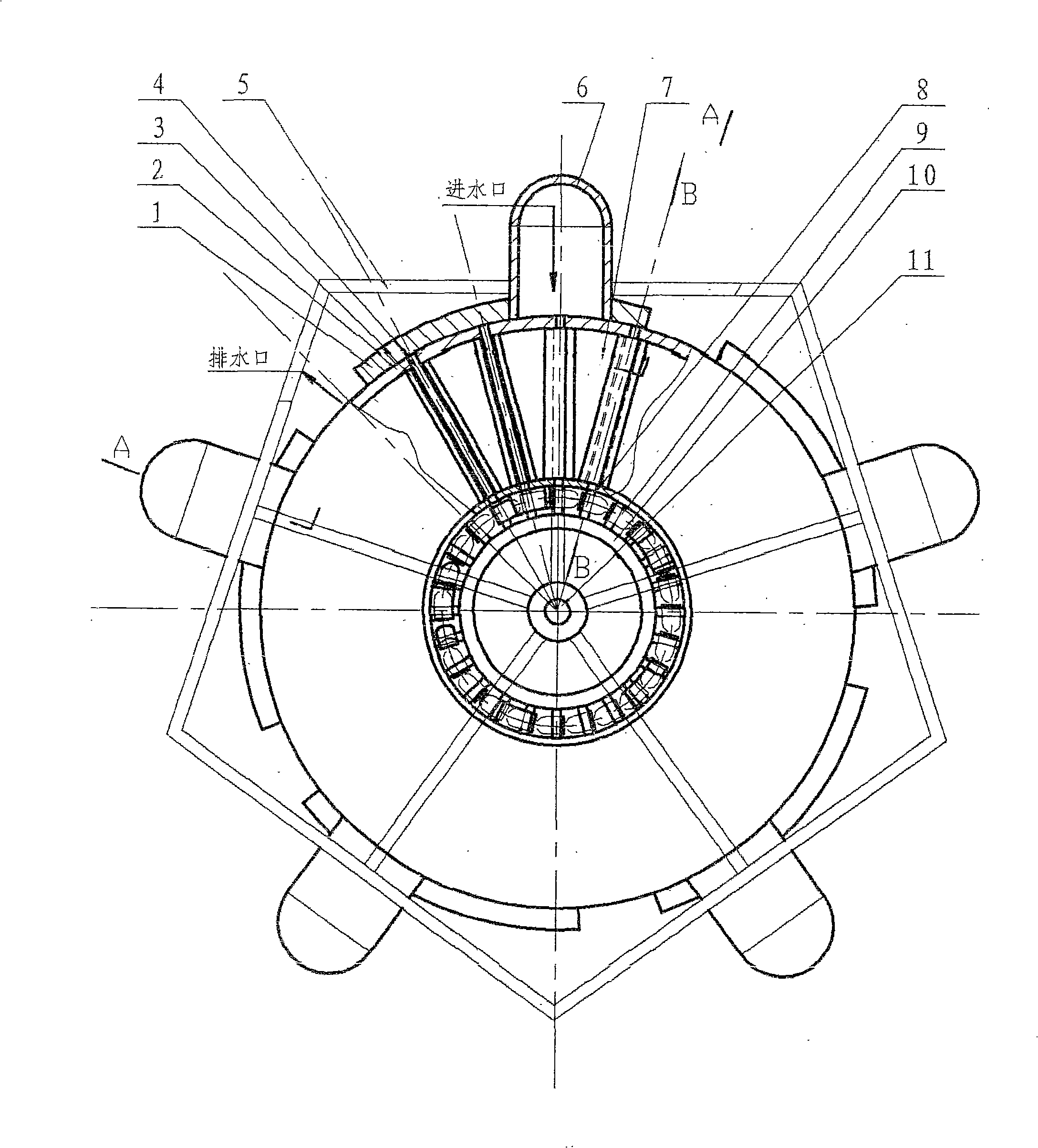

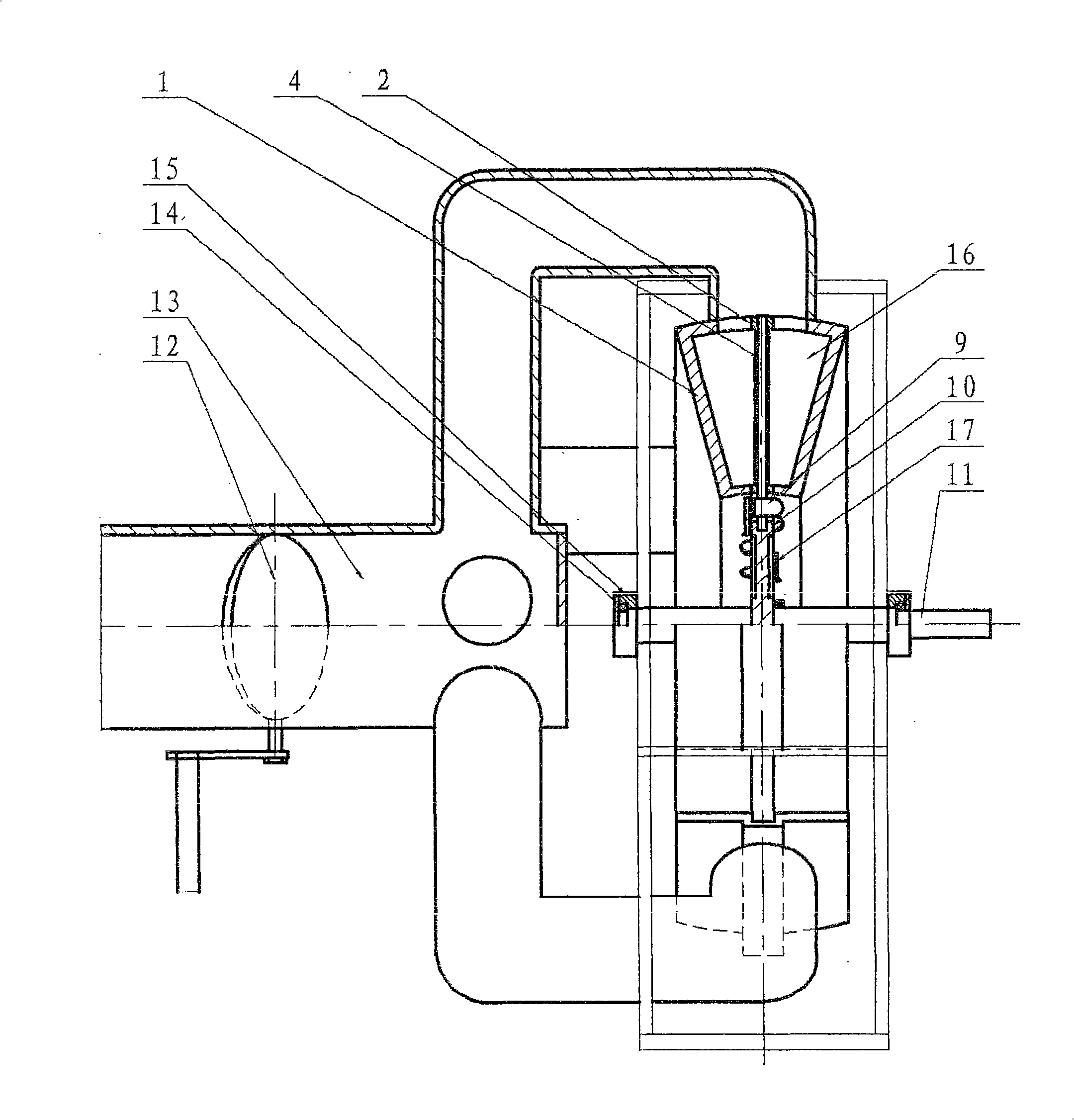

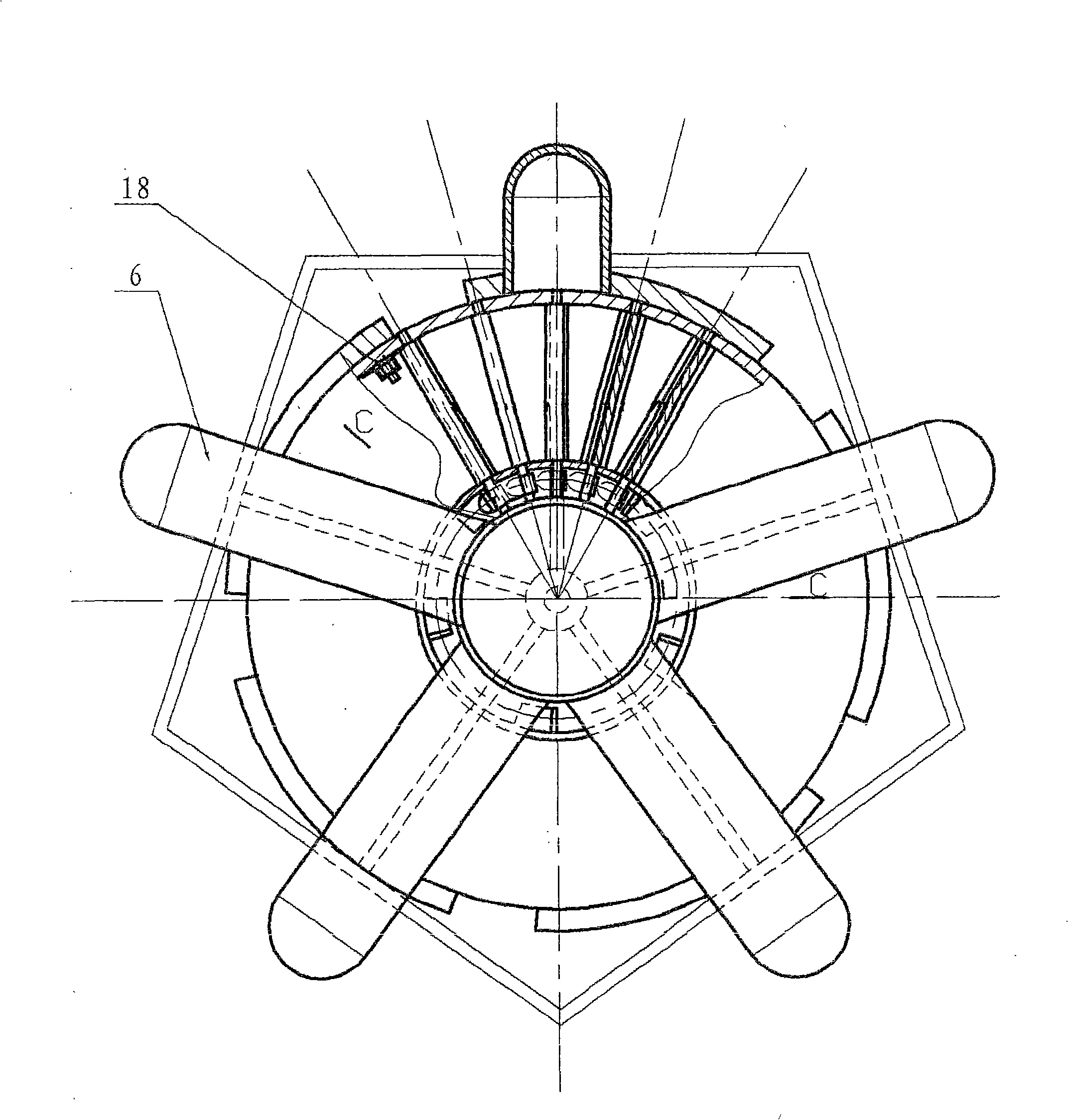

[0020] The present invention will be further described below in conjunction with the drawings and embodiments.

[0021] When the pressurized water passes through the control valve 12, the water divider 13 and the water inlet pipe 6 and enters the various chambers in the hydraulic casing 1, the pressurized water pushes the rotatable blade 3 that has been deployed in the chamber in the working state, and the rotatable blade 3 drives the blade wheel. And the output shaft 11 output torsion, and at the same time, due to the rotation of the blade wheel, the next rotatable blade 3 enters the chamber, the rotation key 9 of the rotatable blade 3 and the fixed key 17 are displaced, and the rotatable blade 3 is passively moved. Enter the working state at 90°; continue to push the blade wheel to rotate, the action of the rotation key 9 of the previous rotatable blade 3 and the fixed key 17 on the other side are reversed by 90° and return to the non-working state, acting on the rotation of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com