Laser welding method

A technology for laser welding and welding surfaces, applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc., which can solve the problems of low power density, insufficient heating, and inability to reduce spatters well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0091] The copper material is taken as an example below to introduce the content of the present invention.

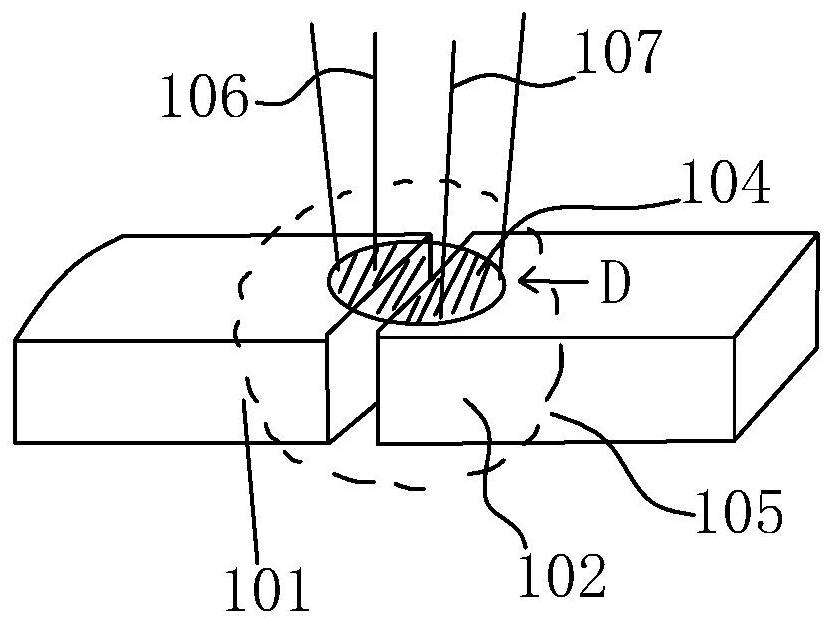

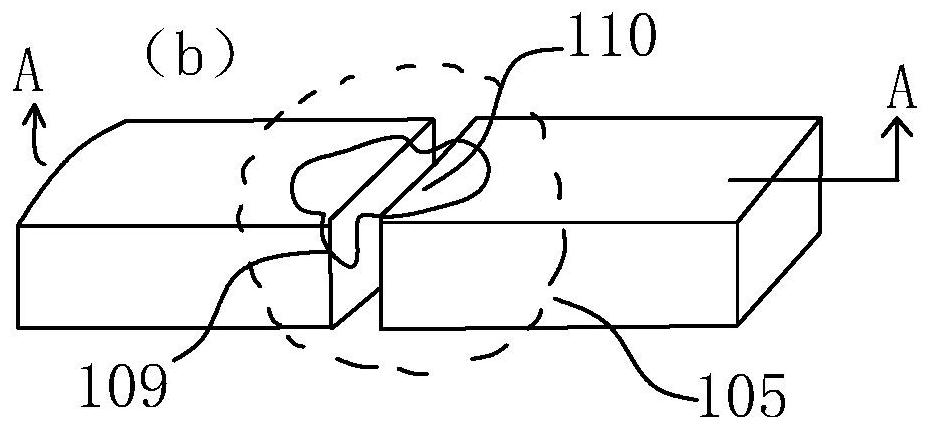

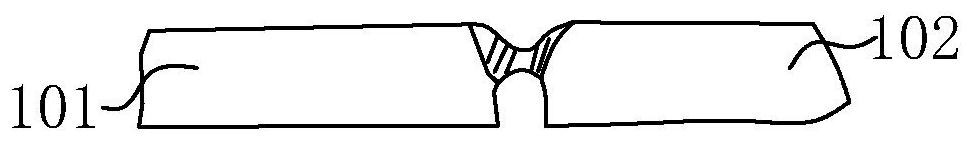

[0092] Fig. 1(a), Fig. 1(b) and Fig. 1(c) are schematic diagrams of the copper material connection method in Example 1 of the present invention.

[0093] A square copper rod 101 is used as the copper material, and the metal to be connected is a 2×3 mm square copper rod 102 with the same shape as the copper rod 101 .

[0094] Arranged butted with each other, the gap d=0.3mm.

[0095] The laser for heating the copper rod 101 and the copper rod 102 has an absorption wavelength of 45%-50% for copper.

[0096] The laser beam is 455nm, 1KW blue laser 103 .

[0097] The diameter of the blue laser spot 104 is D = 2 mm, which is irradiated near the joint 105 .

[0098]In addition, within the blue laser spot 104, high-power infrared laser beams 106, 107 having a wavelength of 1070 nm and a focal spot size of 30 μm were irradiated near the end faces of the respective copper rod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com