Method capable of determining major element(s) in ferrochrome alloy by using X-ray fluorescence melting piece method

A ferrochromium alloy and fusing technology, applied in the field of physical and chemical testing, can solve the problems of low test results, long melting time, material loss of alloy samples, etc., to eliminate the risk of corrosion, solve the effect of particle size effect, and improve the effect of oxidizing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] 2) Preparation and storage of composite oxidant: mix and prepare the required reagent lithium hydroxide monohydrate, boric acid and potassium nitrate solid reagent by mass (4-10): (1-2): 1;

[0029] 3), preparation of working curve standard sample: Weigh 0.1-0.2g standard sample in a porcelain crucible, add compound oxidant and 0.2-0.5g viscosity reducer relative to the quality of standard sample 10-20 times, stir evenly, in Weigh into the platinum crucible the flux lithium tetraborate 30 to 80 times the mass of the standard sample, stir evenly, and make the central area slightly depressed, completely pour the standard sample in the porcelain crucible into the depression, place it in the muffle furnace from room temperature to The speed of 15-20°C / min is raised from room temperature to 770-800°C to complete the pre-oxidation, then transfer the platinum crucible to the melting furnace to melt according to the set procedure, rotate and shake, add the release agent ammonium...

Embodiment 1-6

[0036] Embodiment 1-6, condition A

[0037] First, prepare the required reagents: lithium hydroxide monohydrate, boric acid, potassium nitrate, lithium tetraborate;

[0038] Lithium tetraborate, lithium metaborate, lithium fluoride is the mixed flux that mass ratio is 65:25:10 composition; Potassium bromide, ammonium bromide, stand-by;

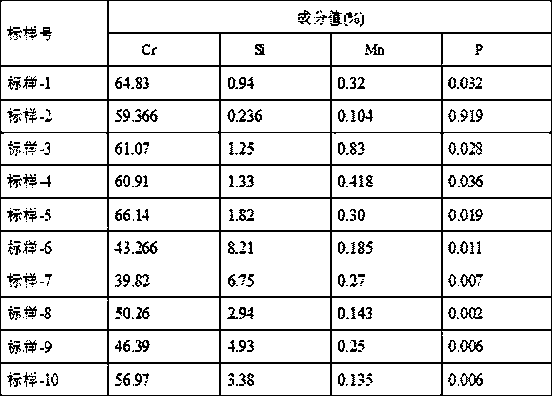

[0039] Second, the selection of standard samples: select 10 ferrochrome standard samples, the content range should cover the analysis sample content, the composition content is shown in the following table 1, the standard sample particles are less than 200 mesh, the standard sample should be processed to 200 mesh and mixed , can pass through a 200-mesh sieve; accurately weigh 0.1500 g of the ground standard sample in a porcelain crucible, add 2.0000 g of composite oxidant lithium hydroxide monohydrate, 0.5000 g of boric acid, and 0.5000 g of potassium nitrate, and add viscosity reducer bromine Potassium chloride 0.2000 g, stir evenly; weigh 7...

Embodiment 7-8

[0059] Embodiment 7-8, condition B

[0060] Medicines and standard samples were prepared according to the conditions of Example 1.

[0061] First, prepare the required reagents: lithium hydroxide monohydrate, boric acid, potassium nitrate, lithium tetraborate;

[0062] Lithium tetraborate, lithium metaborate, lithium fluoride are the mixed flux of 65:25:10 composition by mass ratio, potassium bromide, ammonium bromide, stand-by;

[0063]Second, prepare the standard sample according to Table 1 of Example 1, the sample weight is determined to be 0.1000 grams, add 1.2000 grams of composite oxidant lithium hydroxide monohydrate, 0.2000 grams of boric acid, 0.2000 grams of potassium nitrate, and add 0.5000 grams of viscosity reducer potassium bromide gram, and stir evenly; weigh 8.0000g of lithium tetraborate flux into a platinum crucible, the center area is slightly lower and in a concave shape, pour the uniformly mixed standard sample into the center of the platinum crucible, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com