Fixture for welding Al2O3 ceramic to titanium ring in artificial retina

A retina and ceramic technology is applied in the field of fixtures for welding Al2O3 ceramics and titanium rings in artificial retinas, and achieves the effects of avoiding dislocation, easy operation and use, and reasonable composition and structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

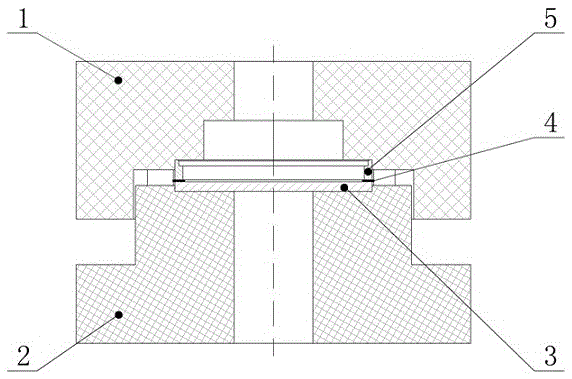

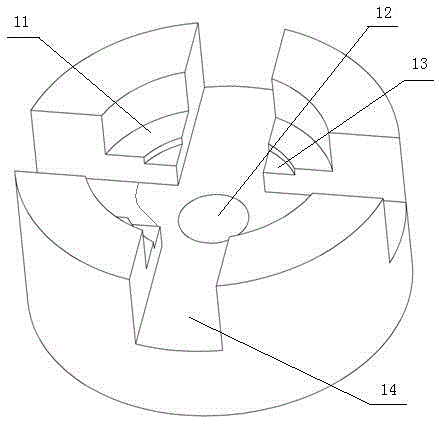

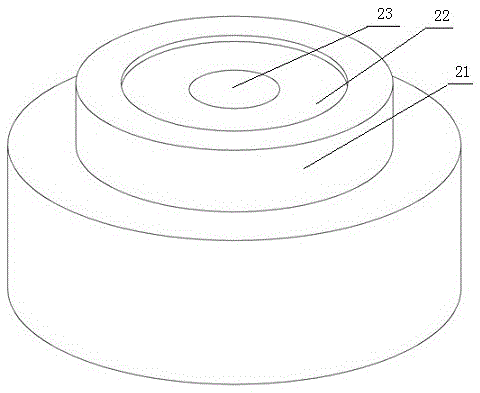

[0016] from figure 1 , figure 2 , image 3 It can be seen that Al in a welded artificial retina 2 o 3 A fixture for ceramic and titanium rings, which includes a graphite base 2, a graphite compact 1, and the like. Described graphite base 2 is provided with a boss 21, is provided with on the boss 21 and is used for placing Al 2 o 3 The groove 22 of the ceramic disc 3 can be Al 2 o 3 A ceramic disc 3 is embedded therein. The graphite briquetting block 1 is provided with a fastening groove 11 matched with the boss 21 on the graphite base 2, and the top surface of the fastening groove 21 is provided with a draw-in groove 13 for pressing the titanium ring 5, The titanium ring can be clamped in the slot, which can not only play a position-limiting role, but also prevent the specimen from being connected to the fixture due to the spreading of the filling material.

[0017] A number of observation fine-tuning windows 14 are provided on the surrounding walls of the fastening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com