Shredding and slicing machine

A planer and shredding technology, which is applied in metal processing and other directions, can solve the problems of high labor intensity and low efficiency, and achieve the effect of reducing labor intensity, high efficiency and convenient extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

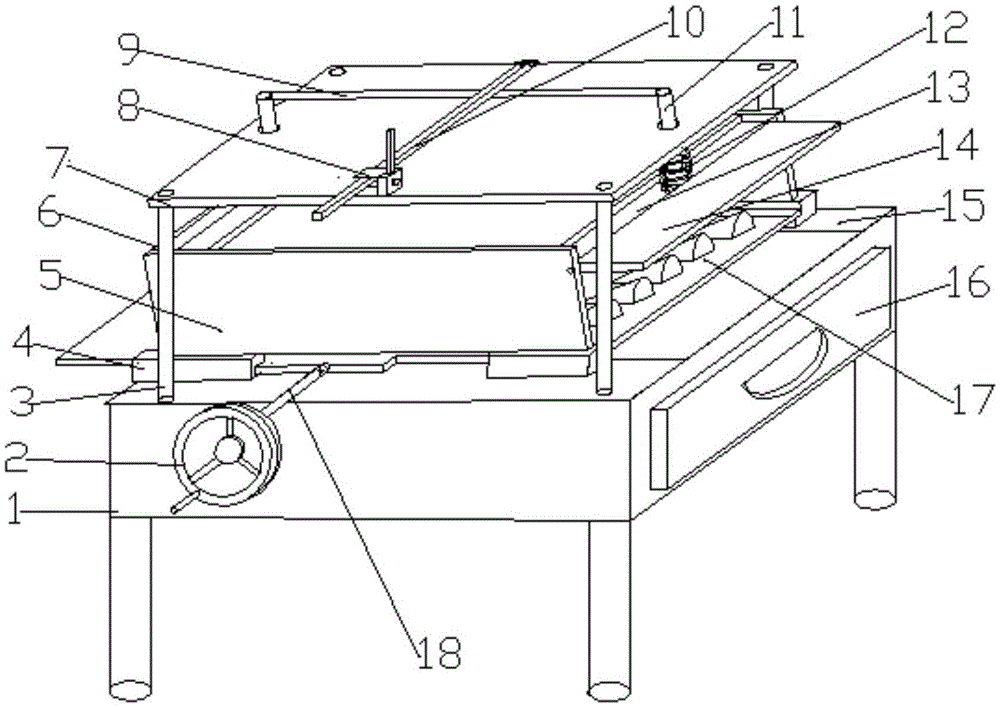

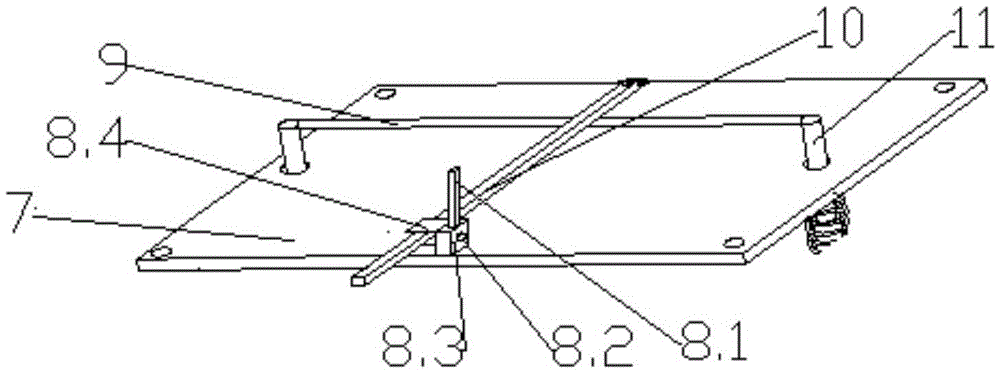

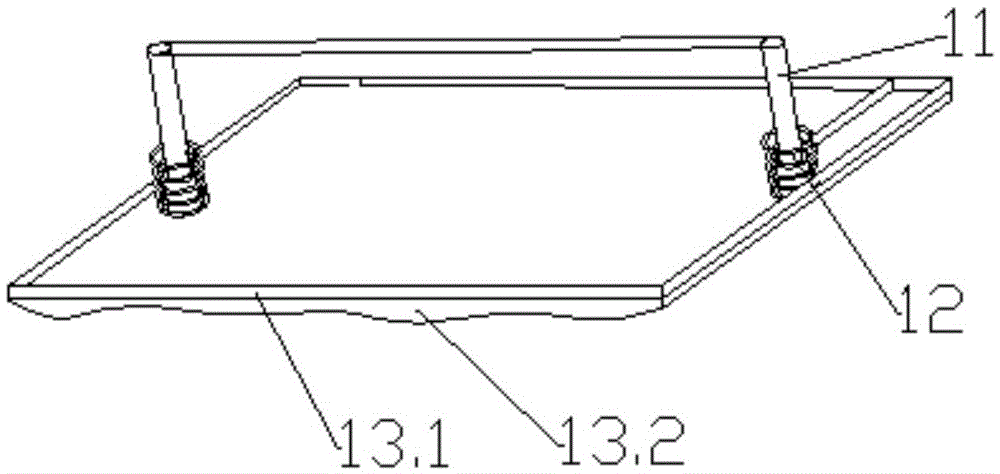

[0025] Such as figure 1 As shown, a slicing and flaking machine includes a box part, a pressing plate part, a planing part and a transmission part.

[0026] The box part includes a base 1 and a top plate 7 above the base 1. The center of the base 1 has a groove in which a drawer accommodating box 16 is installed; the base 1 on the front and rear sides of the groove is symmetrically equipped with guide rails 4. Wherein, two support plates 15 are installed on the front and rear of the upper end surface of the base 1; the guide rail 4 is correspondingly installed on the two support plates 15, and four columns 3 are symmetrically installed on the two support plates 15, and the top plate 7 is installed on the top of four columns 3. The middle part above the base 1 is in an open state, which is convenient for raw materials to enter the drawer storage box 16 after processing, and the drawer storage box 16 end is equipped with a handle, so that better collection and removal of proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com