A plastic switch box integrated injection punching machine

A switch box and punching machine technology, applied in the direction of coating, etc., can solve the problems of punching machine damage, failure to knock out circular plastic plate waste, and circular plastic plate waste pushed to the initial stage, so as to reduce labor load, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

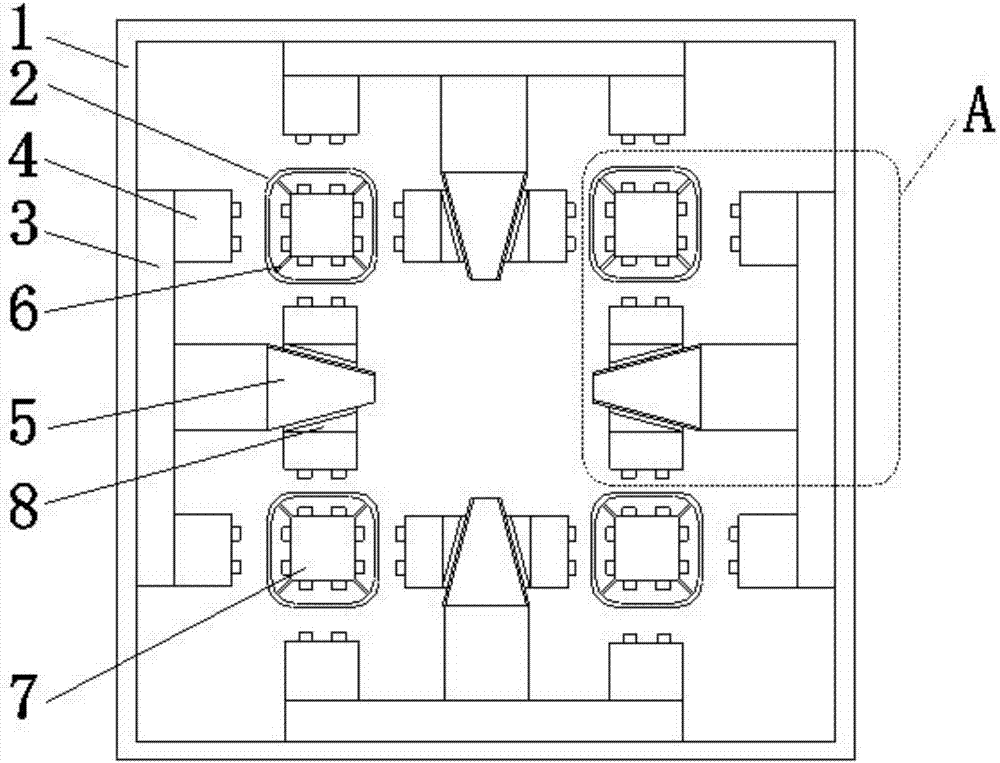

[0032] Such as figure 1 As shown, pour the PVC raw material powder into the heating plastic mixer, start the plastic switch box integrated injection punching machine, set the injection time, injection interval, punching frequency and other working parameters; flow the thermosetting plastic through the injection hole 6 to the In the injection mold, after it is cooled and formed, the side of the injection mold is raised to provide space for the next punching process;

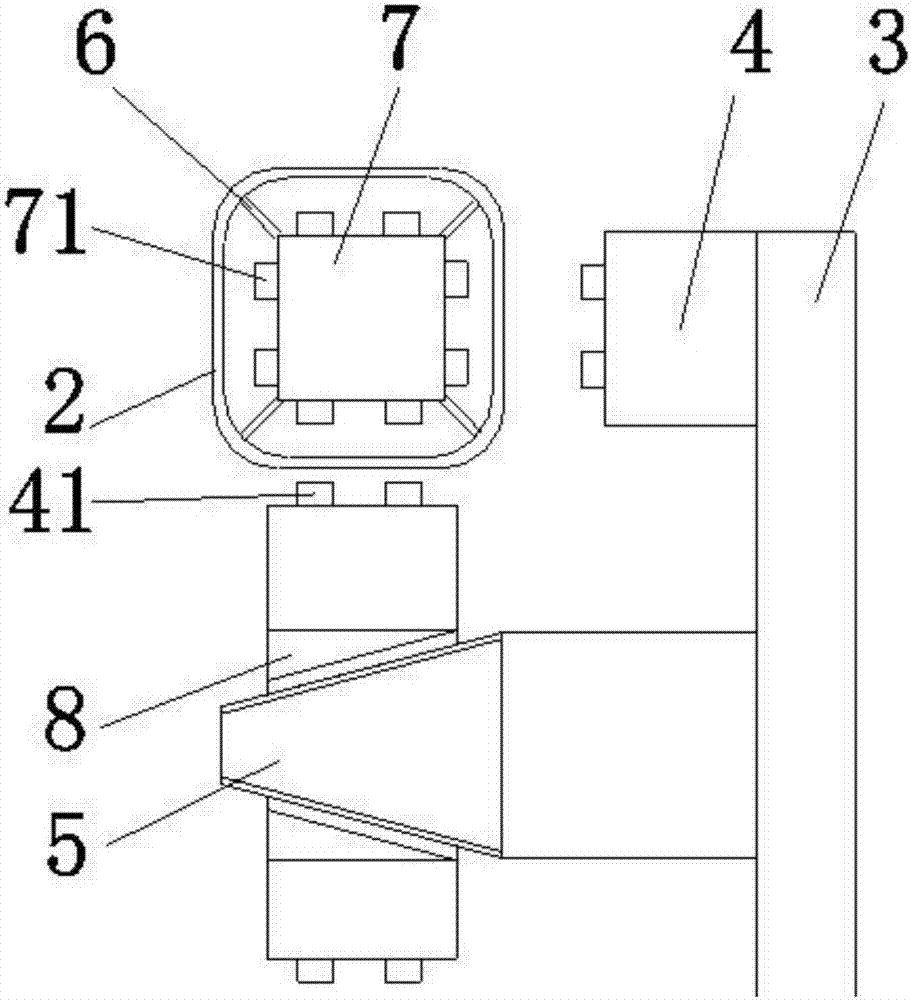

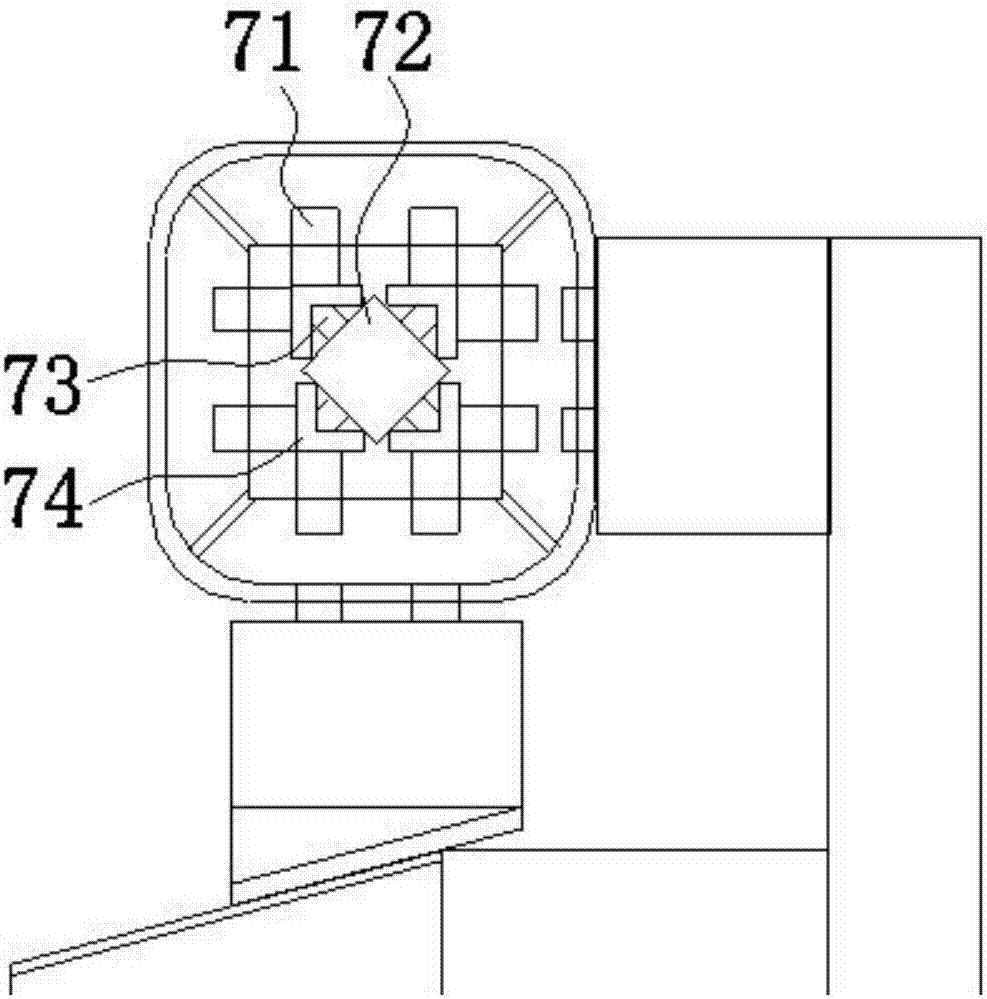

[0033] Such as figure 2 , image 3 As shown, the cylinder push plate 3 quickly pushes the punching knife rest 4 and the inclined plane push rod 5 forward, and the inclined plane of the inclined plane push rod 5 pushes the inclined plane knife rest holder 8 to move forward, and the punching blade 41 before the oil cylinder push plate 3 Punch out the hole 21 on the side of the switch box 2 with the punching blade 41 in front of the inclined knife rest holder 8 at the same time, so that it is evenly stressed on al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com