Multi-color synchronous paste filling machine

A filling machine and color synchronization technology, applied in the field of multi-color synchronous paste filling machines, can solve the problems of material dripping, large workshop space, low efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

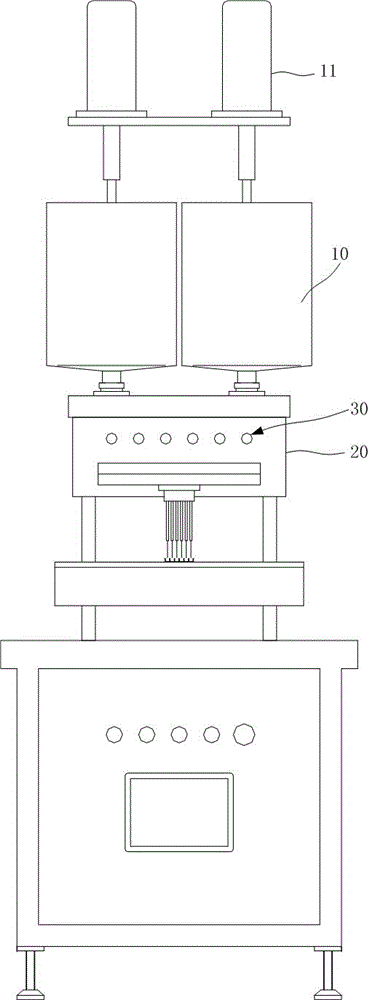

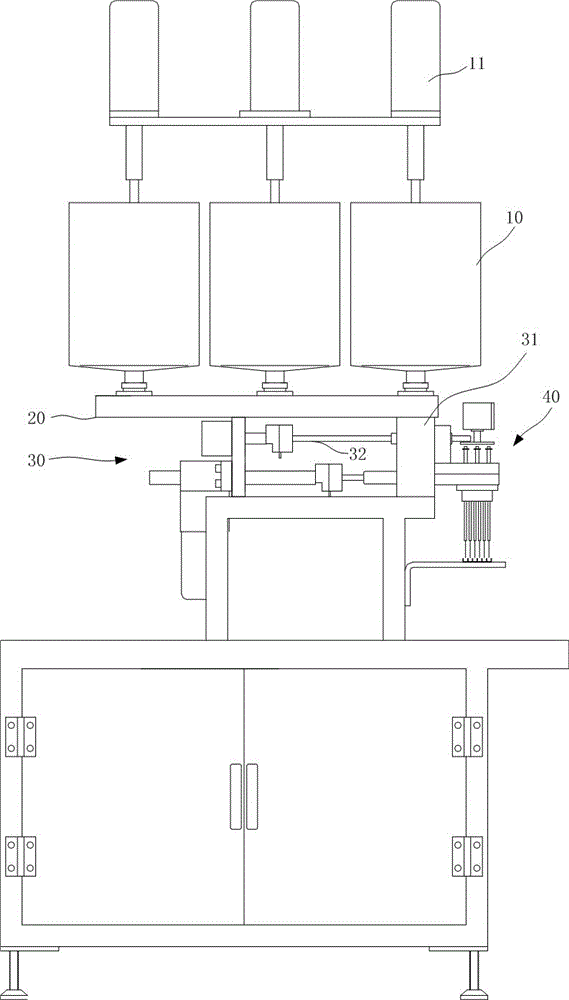

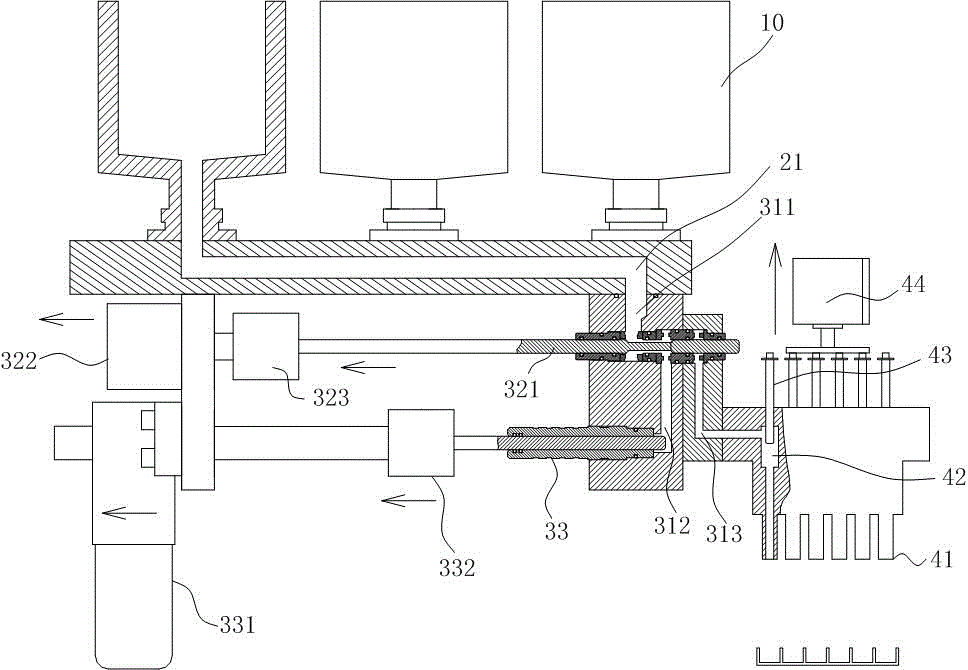

[0016] refer to figure 1 , figure 2 The schematic diagram of the structure is shown.

[0017] A multi-color synchronous paste filling machine according to an embodiment of the present invention includes several material barrels 10, a hot runner plate 20 connecting the outlets of several material barrels 10, a quantitative filling mechanism 30, and an end material withdrawal mechanism 40.

[0018] The hot runner plate 20 is provided with a number of hot runners corresponding to the outlets of several barrels 10 , through which the materials in the material passage 10 are heated at a constant temperature to make the materials have proper fluidity.

[0019] The material barrel 10 is provided with a stirring motor 11 to make the material uniform.

[0020] Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com