Connecting rod scraping-type and lifting-type compression transloading equipment

A scraping and connecting rod technology, applied in the field of connecting rod scraping and lifting compression transfer equipment, can solve the problems of small rotation angle of scraper, failure to reduce garbage, low service life, etc., to avoid visual and olfactory pollution, The effect of improving the displacement adjustment range and improving the service life of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to introduce the present invention in more detail, the present invention will be further described below in conjunction with the accompanying drawings.

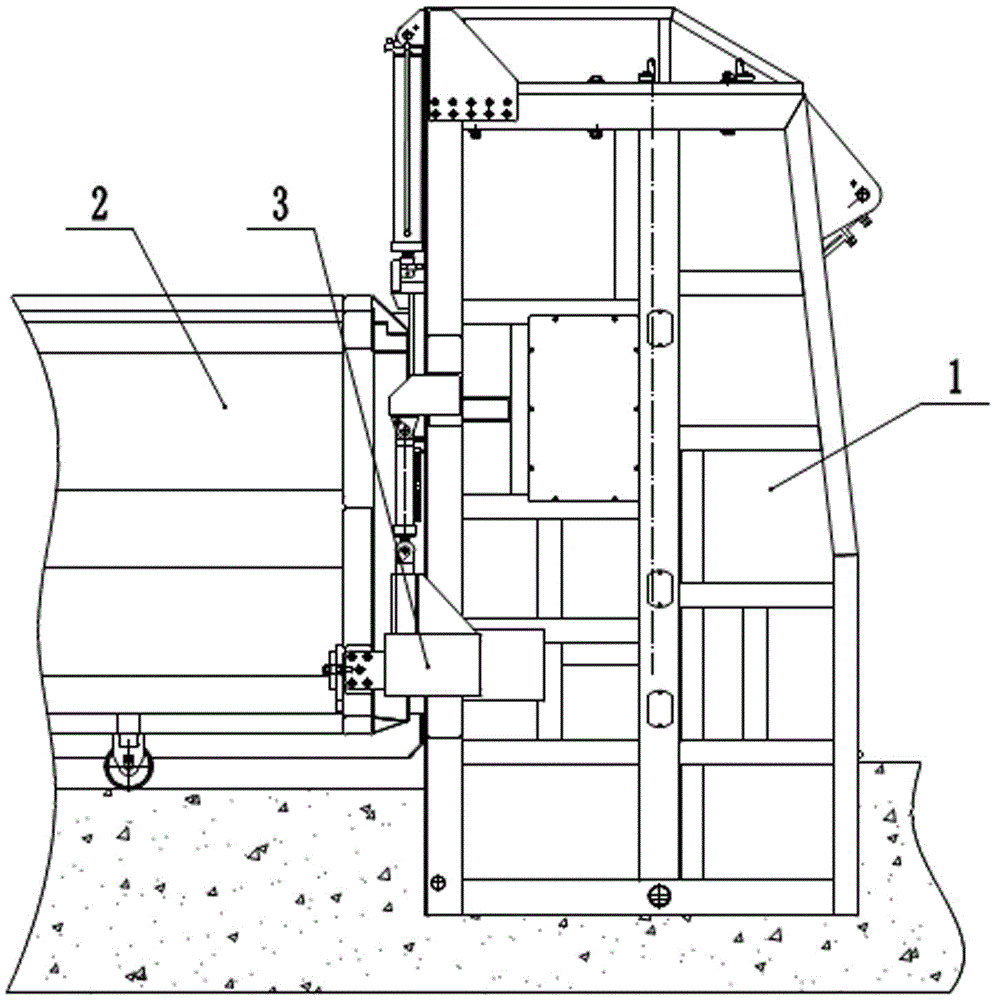

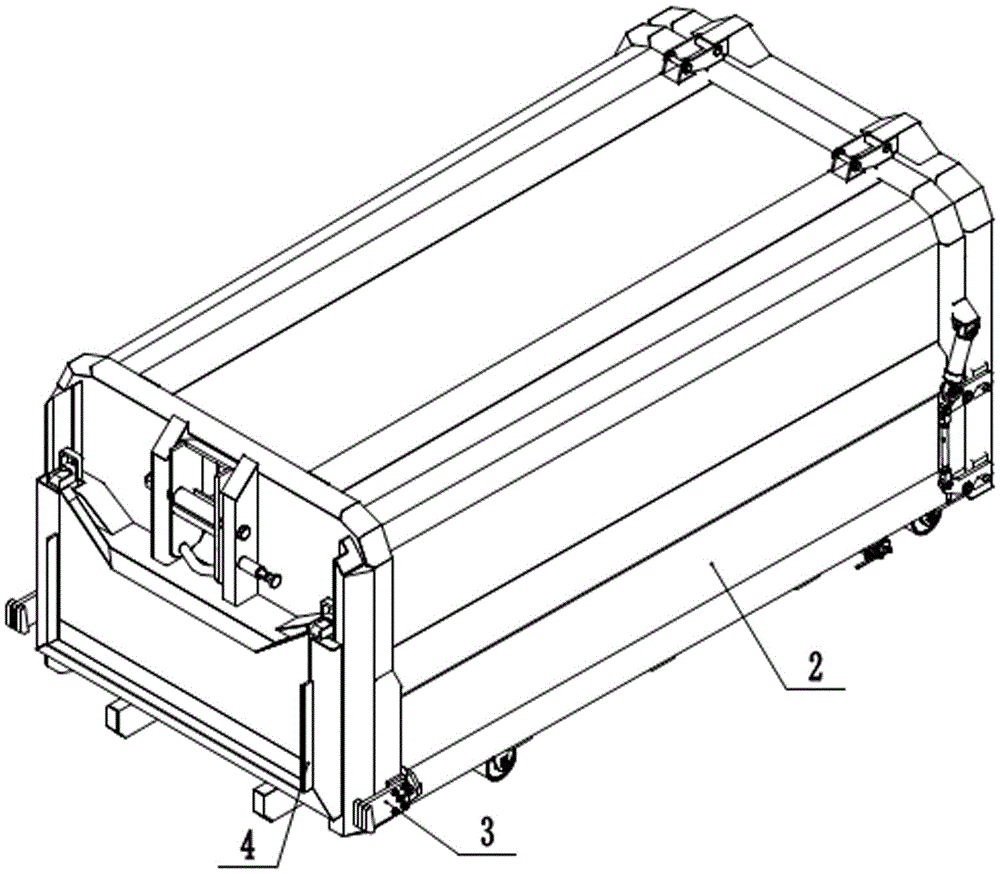

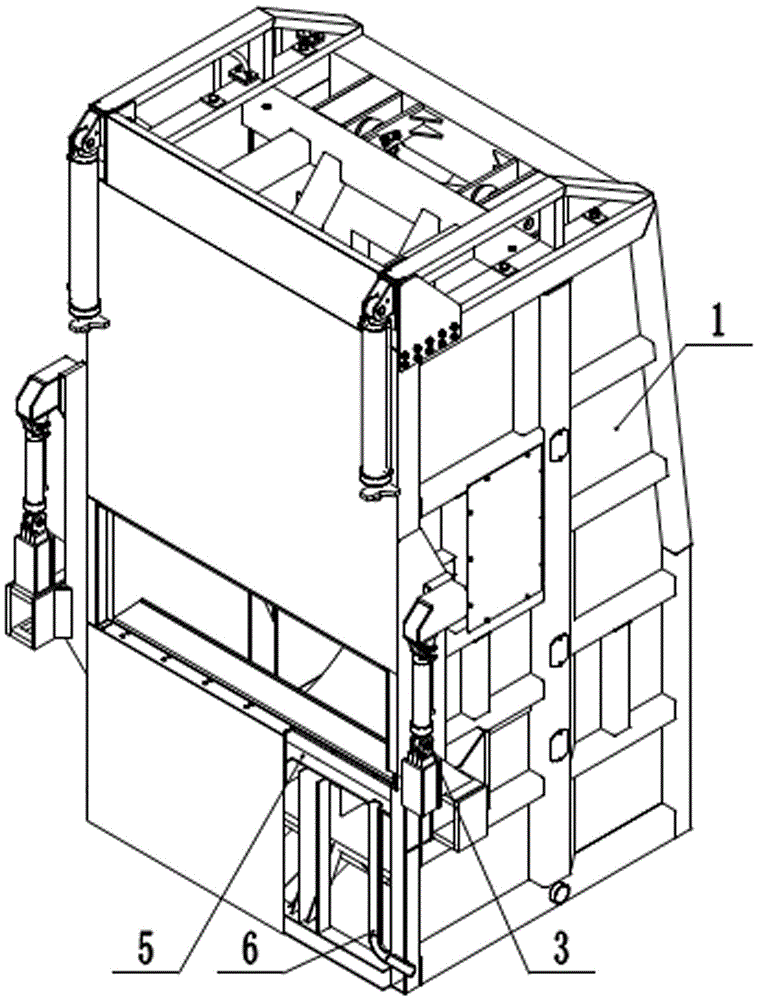

[0039] Such as figure 1 , figure 2 with image 3 As shown, the connecting rod scraping type compression transfer equipment of the present invention includes a compressor 1 with a built-in connecting rod scraping mechanism, a carriage 2, a locking device 3 for docking and locking of the two, and an outer flange 4 from the perspective of large parts. , grooved pipe 5 with holes and drain pipe 6; the locking device 3 is symmetrically installed on the outside of both sides of the compressor 1 and the carriage 2; the front end of the compressor 1 is a vertical plane and is provided with a pushing port for materials to pass through The rear part of the carriage 2 is provided with a feed port docked with the push port of the compressor 1 and a gate that can be lifted vertically, and the feed port is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com