A printing and dyeing water liquid degreasing and filtering device

A technology for oil filtration, printing and dyeing water, which is applied in the direction of grease/oily substance/suspton removal device, liquid separation, separation method, etc. It can solve the problems of unsatisfactory effect and poor automation degree, and achieve good oil removal effect and automation degree high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

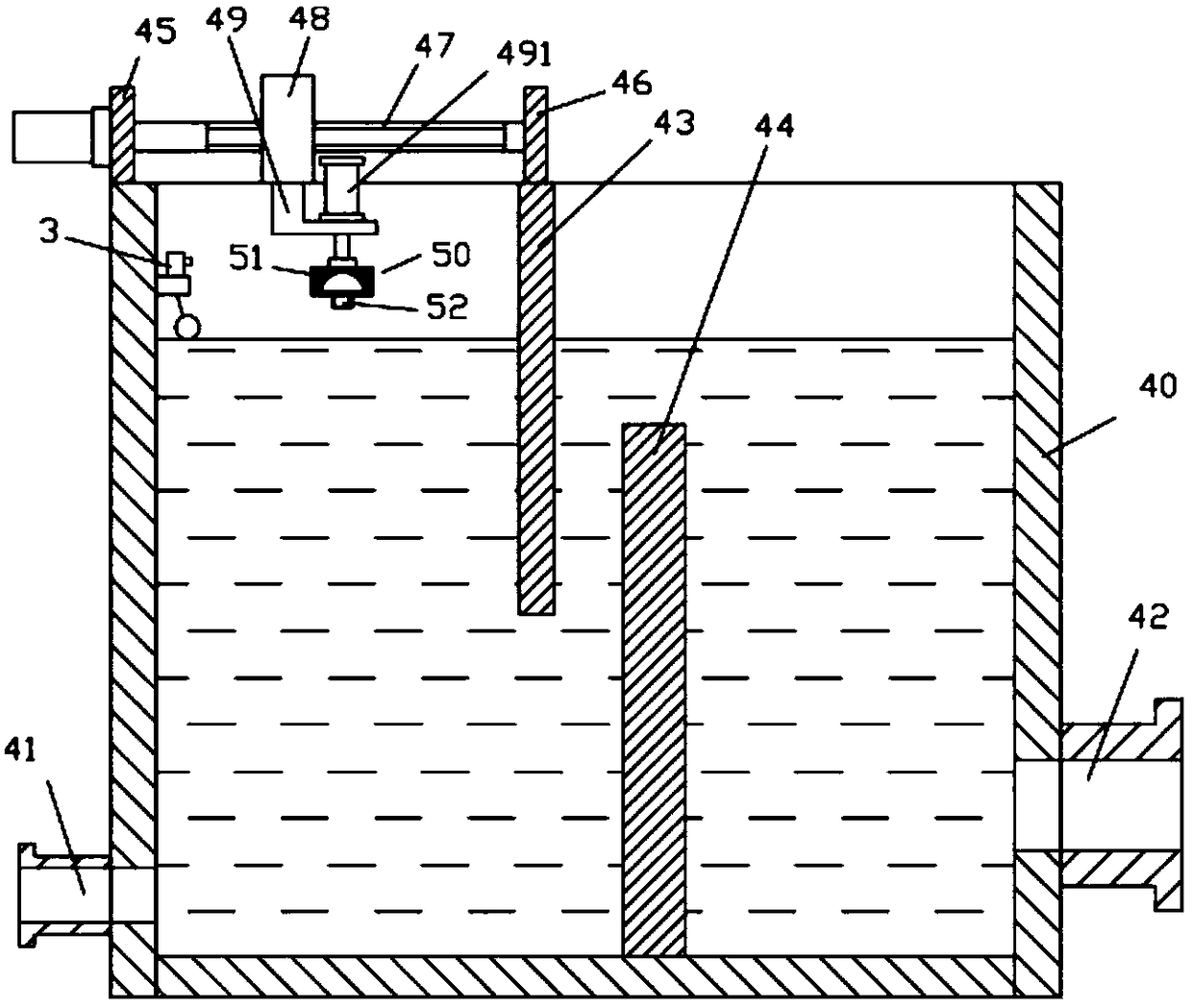

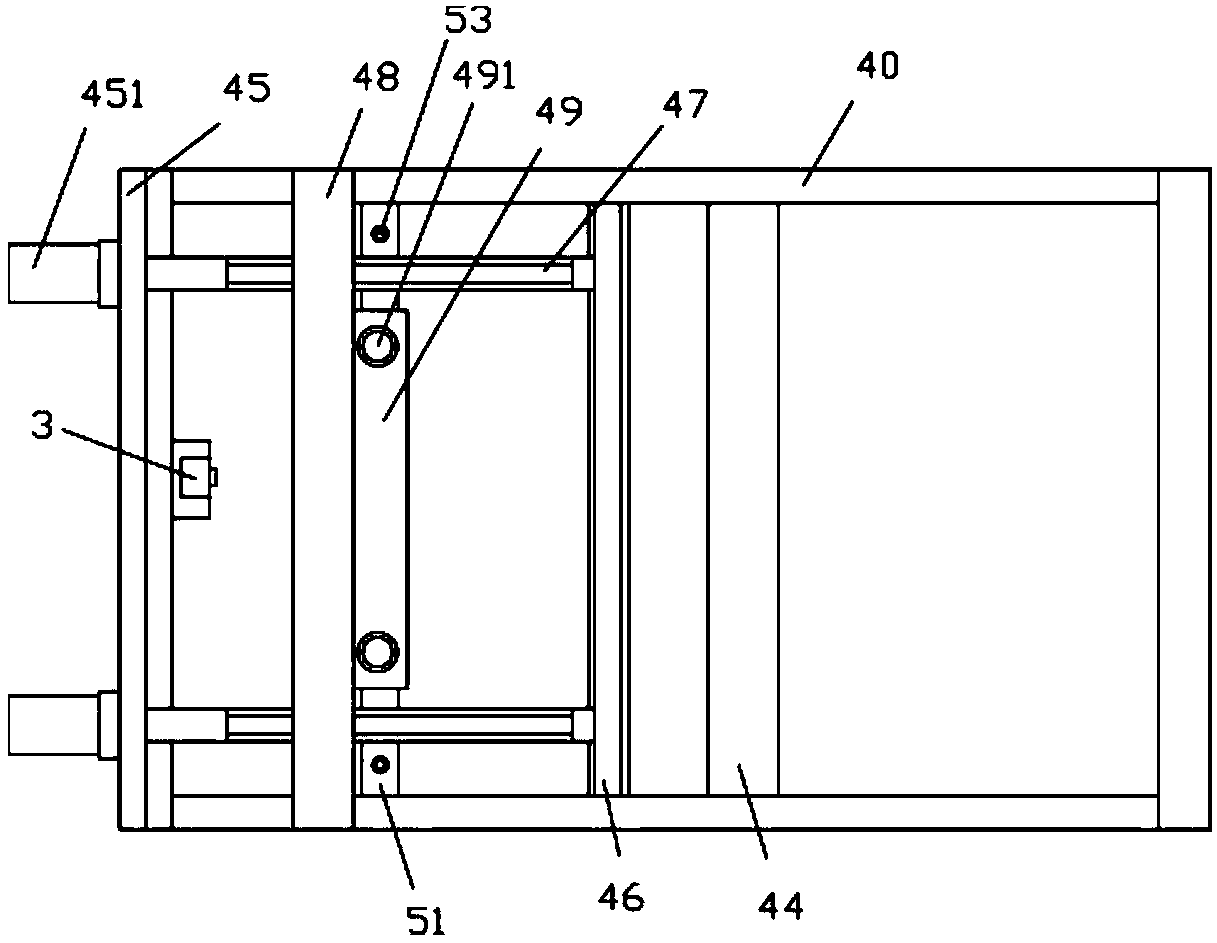

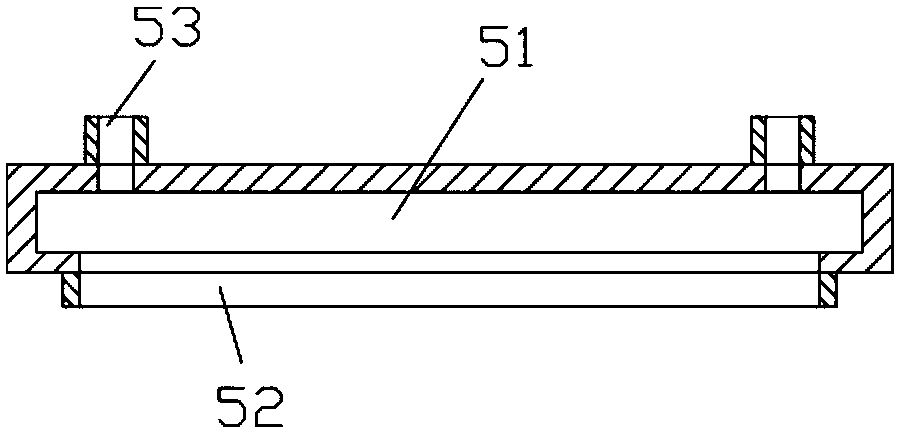

[0016] Examples, see e.g. Figure 1 to Figure 3 As shown, a printing and dyeing water liquid degreasing and filtering device includes a degreasing and filtering box 40, and the lower part of the left side plate of the said degreasing and filtering box 40 is connected with a degreasing liquid inlet pipe 41, and the degreasing and filtering box The bottom of the right side plate of 40 is connected with oil removal liquid outlet pipe 42, and the middle part of oil removal filter casing 40 is fixed with upper dividing plate 43 and lower dividing plate 44, and upper dividing plate 43 is on the left side of lower dividing plate 44, and upper dividing plate 43 The top surface of dividing plate 43 surpasses the upper end surface of degreasing filter casing 40 or is flat with the upper end surface of degreasing filtering casing 40, and the bottom end surface of lower dividing plate 44 is fixed on the bottom plate of filtering casing 40, and upper dividing plate 43 and the two sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com