A large gas turbine intake system cleaning equipment

An air intake system and gas turbine technology, applied in fuel air filters, charging systems, mechanical equipment, etc., can solve the problems of uneven purging, long operation time, dust pollution, etc., saving labor, blowing The effect of even sweeping and stable air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

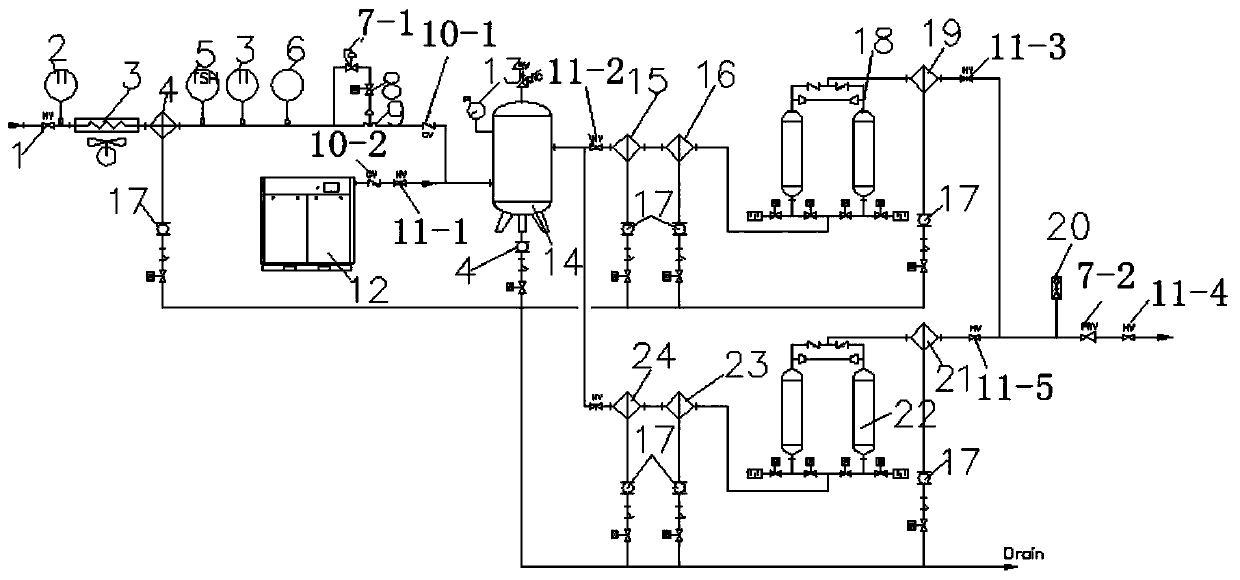

[0014] Embodiment one: if figure 1 As shown, the present invention includes a twin-screw air compressor 12, the twin-screw air compressor 12 is connected to a first air storage tank 14, and the other end of the first air storage tank 14 is connected to a solenoid valve through a first one-way valve 10-1 8, the twin-screw air compressor 12 is provided with a second one-way valve 10-2 and a first valve 11-1, and the electromagnetic valve 8 is connected with the first decompression valve 7-1 and the first one-way valve 10-1. The pressure switch 6, the thermometer 2, and the temperature switch 5 are connected in series. The other end of the thermometer 2 is connected to the air-cooled air cooler 3 through the cyclone oil-water separator, and the other end of the air-cooled air cooler 3 is connected to the high temperature The valve 1 is connected; the first gas storage tank 14 is provided with a shockproof glycerin pressure gauge 13 and a safety valve, the first gas storage tank 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com