Method for preparing antimicrobial surface on biological medical material surface

A biomedical material, surface amination technology, applied in coating and other directions, can solve the problems of complex reaction process and limited substrate, and achieve the effect of simple operation, wide applicability, and easy reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

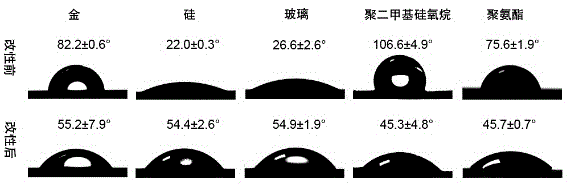

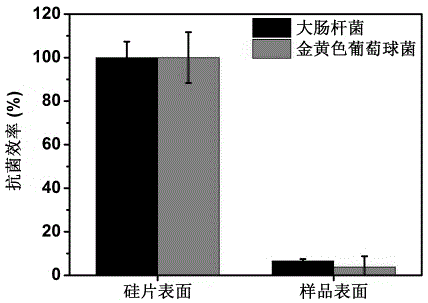

[0060] Combining layer-by-layer assembly technology and host-guest interaction to prepare antibacterial surfaces on the surface of single crystal silicon wafers

[0061] The monocrystalline silicon wafers cleaned ultrasonically with acetone solution were pretreated with "piranha" solution (sulfuric acid: hydrogen peroxide = 7:3, volume ratio), and then placed in 3-aminopropyl-triethoxysilane (APTES) react in a toluene solution for 18 hours to obtain a monocrystalline silicon wafer with surface amination. A polyanion P(AA-Ada) solution and a polycation PAH solution were prepared respectively, and the solvent was acetic acid / sodium acetate buffer solution with a pH value of 5.0 and a concentration of 0.05 mol / liter. Soak the aminated monocrystalline silicon wafer in the P(AA-Ada) solution, wash it with acetic acid / sodium acetate buffer solution to remove the weakly bonded polymer, and then soak it in the PAH solution. After cleaning, a P (AA-Ada) / PAH bimolecular layer, this pro...

Embodiment 2

[0065] Combining layer-by-layer assembly technology with host-guest interaction to prepare antibacterial surface on glass surface

[0066] The glass slides ultrasonically cleaned with acetone solution were pretreated with "piranha" solution (sulfuric acid: hydrogen peroxide = 7:3, volume ratio), and then placed in 3-aminopropyl-triethoxysilane (APTES) toluene After reacting in the solution for 18 hours, the surface-aminated glass flakes were obtained. A polyanion P(AA-Ada) solution and a polycation PAH solution were prepared respectively, and the solvent was acetic acid / sodium acetate buffer solution with a pH value of 5.0 and a concentration of 0.05 mol / liter. Soak the aminated glass piece in the P(AA-Ada) solution, wash it with acetic acid / sodium acetate buffer solution to remove the weaker polymer, and then soak it in the PAH solution. After cleaning, a P(AA-Ada) is obtained on the surface. -Ada) / PAH bimolecular layer, this process is repeated several times to finally reac...

Embodiment 3

[0070] Combining layer-by-layer assembly technology with host-guest interaction to prepare antibacterial surface on the surface of gold-plated single crystal silicon wafer

[0071] Pretreat the gold-plated single crystal silicon wafers cleaned by the UV-ozone meter with a mixed solution of ammonia, hydrogen peroxide and deionized water (ammonia: hydrogen peroxide: deionized water = 1:1:5, volume ratio), and then place React overnight in an aqueous solution of mercaptoethylamine hydrochloride to obtain a gold-plated single-crystal silicon chip whose surface is aminated. A polyanion P(AA-Ada) solution and a polycation PAH solution were prepared respectively, and the solvent was acetic acid / sodium acetate buffer solution with a pH value of 5.0 and a concentration of 0.05 mol / liter. Soak the aminated gold-plated single crystal silicon wafer in the P(AA-Ada) solution, wash it with acetic acid / sodium acetate buffer solution to remove the weakly bonded polymer, and then soak it in th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap