A kind of photochromic composition and application

A technology of photochromism and composition, which is applied in applications, color-changing fluorescent materials, household appliances, etc., and can solve the problems of poor light fastness and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

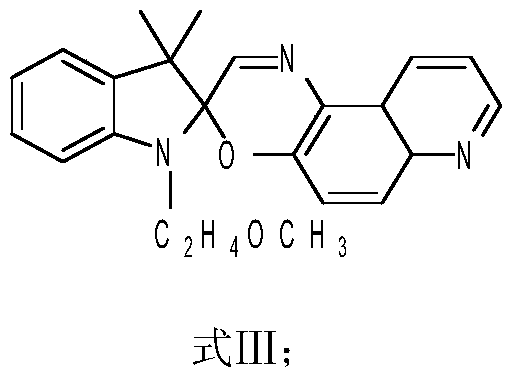

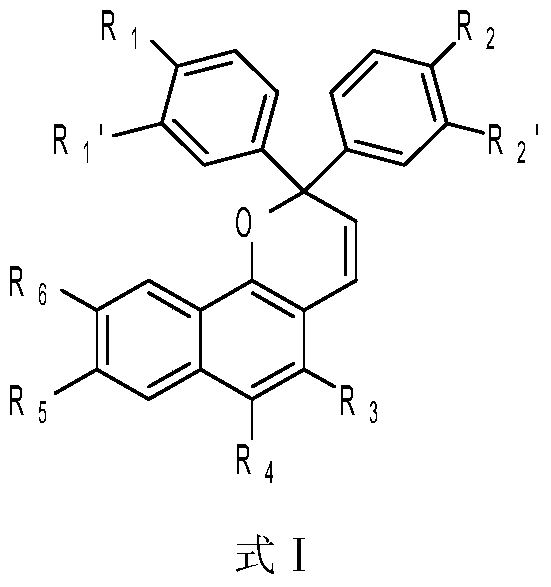

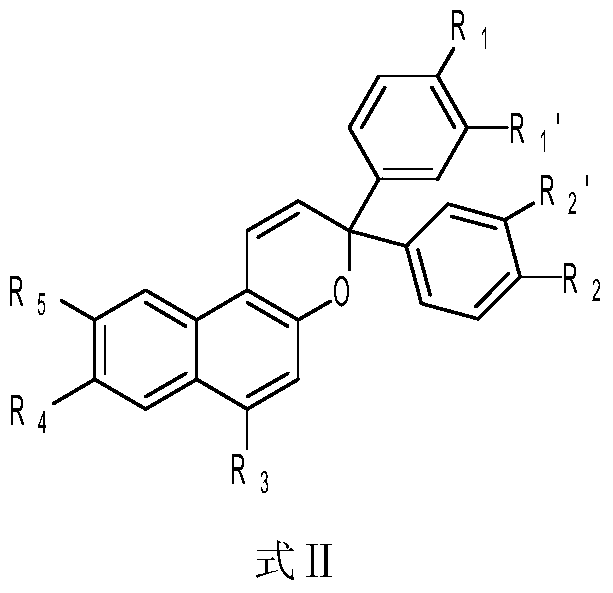

Method used

Image

Examples

Embodiment 1

[0061] Preparation of photochromic composition 1: Photochromic compound A 0.03g, anionic water-based polyurethane WPU-1, solid content 35(w)%, 3.4g, obtained after uniform mixing.

[0062]

[0063] Synthesis of waterborne polyurethane WPU-1:

[0064] Add dehydrated polycarbonate diol (molecular weight 1000, hydroxyl value KOH 110mg / g, industrial grade, Qingdao Deqing Chemical) and hexamethylene diol into a four-necked flask equipped with an electric stirrer, a thermometer, and a reflux condenser. Isocyanate (reagent grade, Shanghai Ziyi Reagent Factory), gradually heated up to 60-65°C, and reacted for about 2 hours. Add the hydrophilic chain extender DMPA (2,2-dimethylolbutyric acid), raise the temperature to about 80°C, and add acetone to dilute. Then, when the temperature is lowered to 30-40°C, slowly add deionized water under high-speed stirring for emulsification. The acetone was removed under vacuum to obtain polyester anionic emulsion WPU-1 with a solid content of 3...

example 2

[0070] Preparation of photochromic composition 2: photochromic compound B0.04g, anionic waterborne polyurethane WPU-2, solid content 38%, 2.0g, magnesium oxide 0.2g, 1,2,3-benzotriazole 0.015g , adjusted to pH=7.5 with ammonia water, obtained after mixing uniformly.

[0071]

[0072] Synthesis of waterborne polyurethane WPU-2:

[0073] Add dehydrated polycaprolactone polyol (molecular weight 1000, hydroxyl value KOH330~350mg / g, industrial grade, Japan Daicel Chemical) and hydrogenated benzene Dimethylene diisocyanate (Takenate 600, Bayer Company), gradually heated up to 60-65°C, and reacted for about 2.0 hours. Add the chain extender 1,4-butanediol, raise the temperature to about 80°C, and add acetone to dilute. Then, when the temperature is lowered to 30-40°C, slowly add deionized water under high-speed stirring for emulsification. The acetone was removed under vacuum to obtain polyester anionic emulsion WPU-2 with a solid content of 38%.

[0074] Preparation of photoc...

example 3

[0079] Preparation of photochromic composition 3: Photochromic compound C0.001g, nonionic waterborne polyurethane WPU-3: 2.1g, solid content 40%, zinc oxide 0.2g, aluminum oxide 0.2g, obtained after mixing uniformly.

[0080]

[0081] Synthesis of waterborne polyurethane WPU-3:

[0082] Add dehydrated polyether diol (N-210, industrial grade, Tianjin Petrochemical Company No. Inject dry nitrogen, start stirring and gradually heat up to 70°C, add isophorone diisocyanate (IPDI, industrial grade, Shanghai Jinjinle Industrial Co., Ltd.) dropwise, add dibutyltin dilaurate and ethylene glycol, and react for about 3 hours; Add polyethylene glycol monomethyl ether and react for about 0.5 hours; cool down to below 15°C, slowly add deionized water under high-speed stirring for emulsification. The acetone was removed under reduced pressure under vacuum to obtain a nonionic aqueous polyurethane dispersion WPU-3 with a solid content of 40%.

[0083] Preparation of Photochromic Article ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com