Tray wafer positioning system, method and mocvd equipment

A positioning method and positioning system technology, applied in the semiconductor field, can solve problems such as unstable rotation of the tray, uneven weight distribution of the wafer, and reduced uniformity of film growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

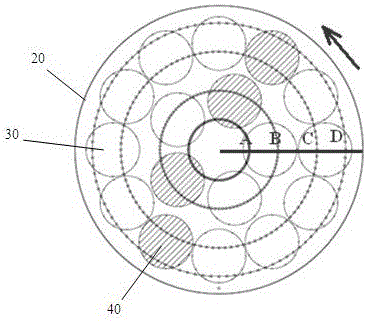

[0068] A method for positioning a wafer on a tray provided in an embodiment of the present invention, which includes the following steps:

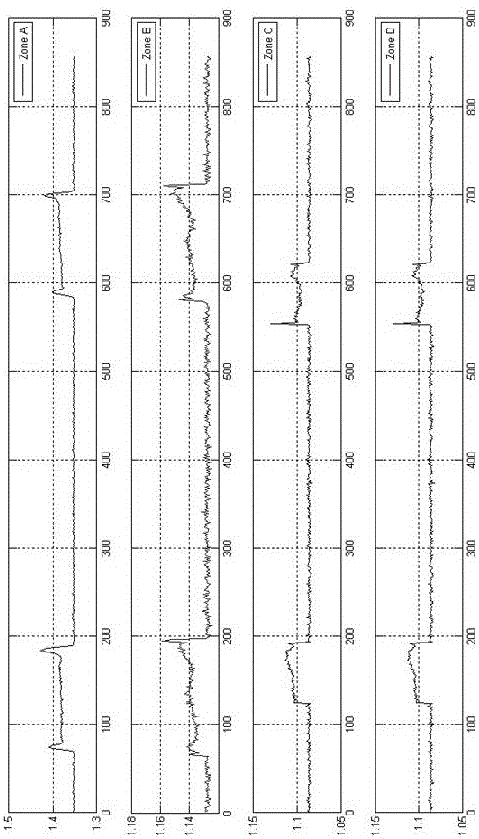

[0069] When the tray rotates, measure optical signals corresponding to at least two circles of wafers on the tray to obtain at least two sets of optical signal sequences;

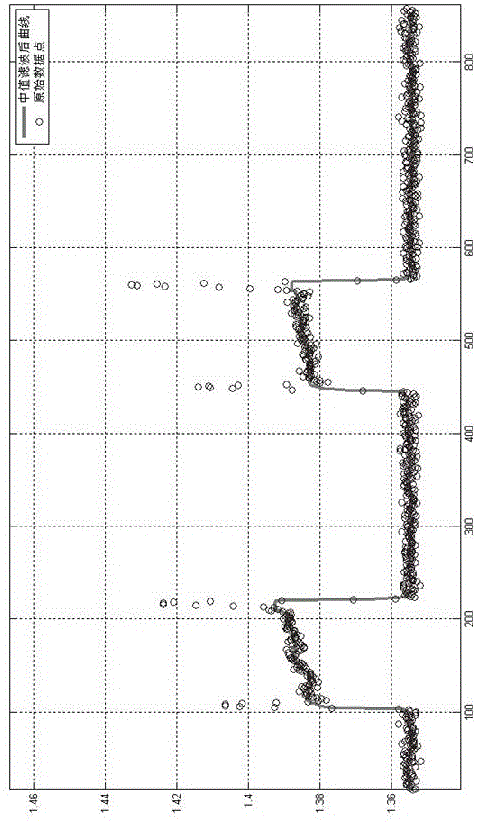

[0070] Matching the measured at least two groups of optical signal sequences as a whole with the preset position information template; the position information template includes the corresponding position information templates of the at least two circles of wafers, and each circle of wafers The corresponding position information template includes the number of each groove in the corresponding circle of grooves, the coordinate information of each groove, and the wafer placement information in each groove;

[0071] Find out the positions of the optical signals corresponding to each circle of wafers in their respective sequences when the matching degree is the highest, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com