Rare earth oxide feeding control method for rare earth electrolytic bath

A technology of rare earth oxidation and control method, which is applied in the direction of electrolytic components, electrolytic process, etc., to achieve the effect of low labor intensity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] Example 1:

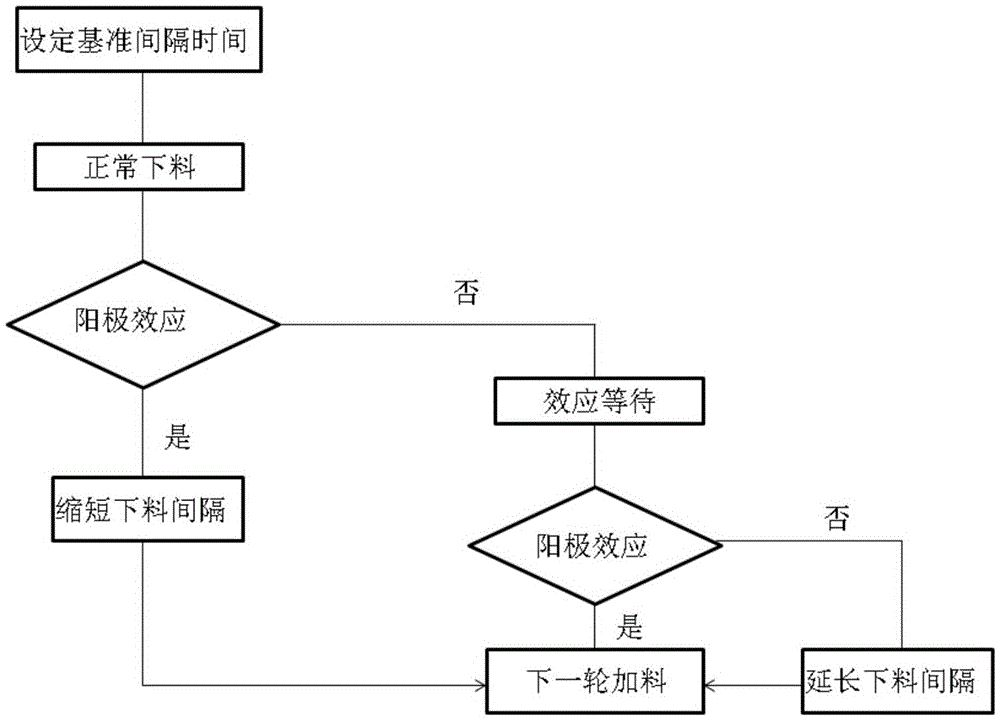

[0022] In this embodiment, the anode effect coefficient is set to 0.05 times / day, the effect interval is 20 days, and the automatic feeding system is set to perform feeding every 3 minutes. During the effect interval, there are two situations where the cell resistance rise rate is higher than 50pΩ / s and the cell voltage fluctuation range is greater than 200mV / s, and the cell voltage rises rapidly above 8.0V for a duration of 10s, it is determined that the anode effect has occurred, and the The anode effect processing is performed. After the anode effect processing is finished, it is transferred to the next round of feeding cycle. At the same time, because the anode effect occurs in the first part of the effect interval of the three equal divisions, the blanking interval is shortened by 10s.

Example Embodiment

[0023] Example 2:

[0024] In this embodiment, the anode effect coefficient is set to 0.05 times / day, the effect interval is 20 days, and the automatic feeding system is set to perform feeding every 1 minute. During the effect interval, the rise rate of cell resistance is higher than 50pΩ / s, the noise intensity of cell is higher than 15mV, the amount of rare earth oxide added in the past 36h is lower than twice the consumption, and the local anode current density is reduced by 70% in 10s. In many cases, the anode effect prediction is carried out and the anode effect processing is carried out. After the anode effect processing is finished, it is transferred to the next round of feeding cycle. At the same time, because the anode effect occurs in the latter part of the effect interval of three equal divisions, the feeding interval is shortened by 2s.

Example Embodiment

[0025] Example 3:

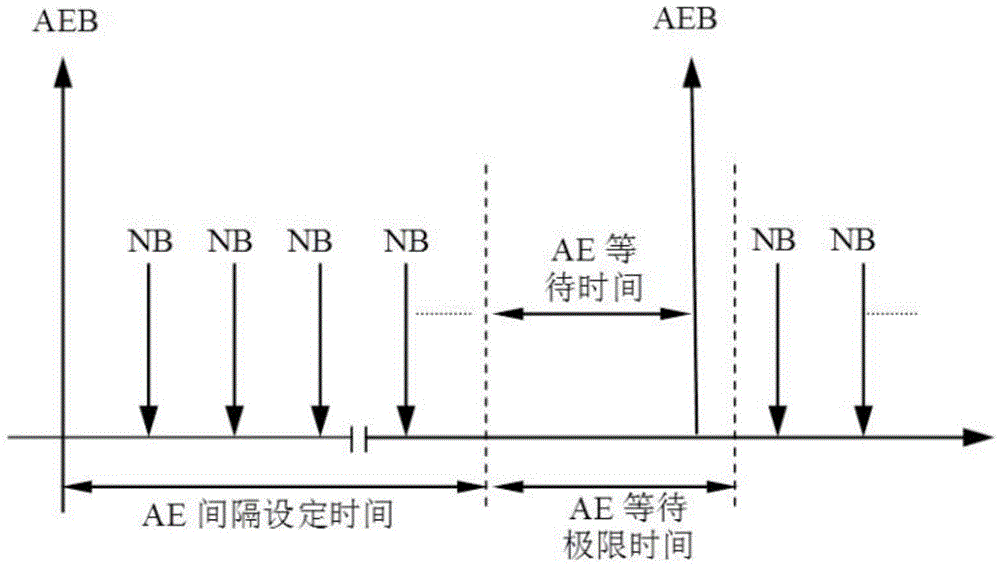

[0026] In this embodiment, the anode effect coefficient is set to 0.05 times / day, the effect interval is 20 days, and the automatic feeding system is set to perform feeding every 100 seconds. Since the anode effect does not occur within the effect interval, when the effect waiting start time is reached, the feeding is stopped and the effect waiting is entered. The anode effect occurs within the preset effect waiting time of 16h, so the anode effect processing is performed immediately, and then the next feeding cycle is transferred, and the blanking interval is not adjusted.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap