A method of locking and adjusting the steel beam of a long-span cable-stayed bridge

A cable-stayed bridge, long-span technology, applied in cable-stayed bridges, bridges, bridge forms, etc., can solve problems such as occupying jack resources, and achieve the effects of high installation accuracy, easy operation, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0030] see figure 1 , figure 2 As shown, the embodiment of the present invention provides a method for locking and adjusting the steel girder of a long-span cable-stayed bridge with convenient layout and flexible and precise operation, which includes the following steps:

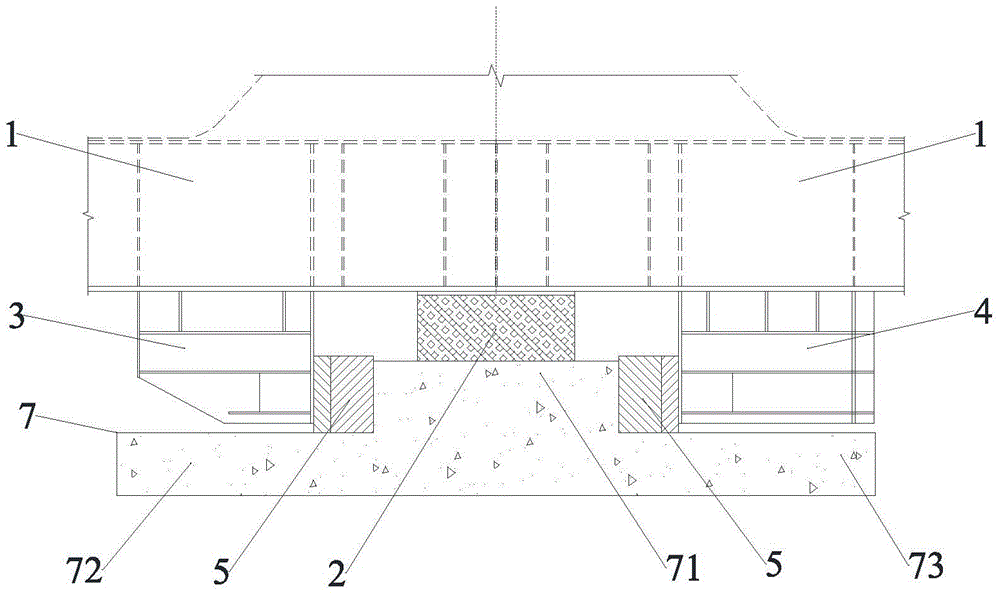

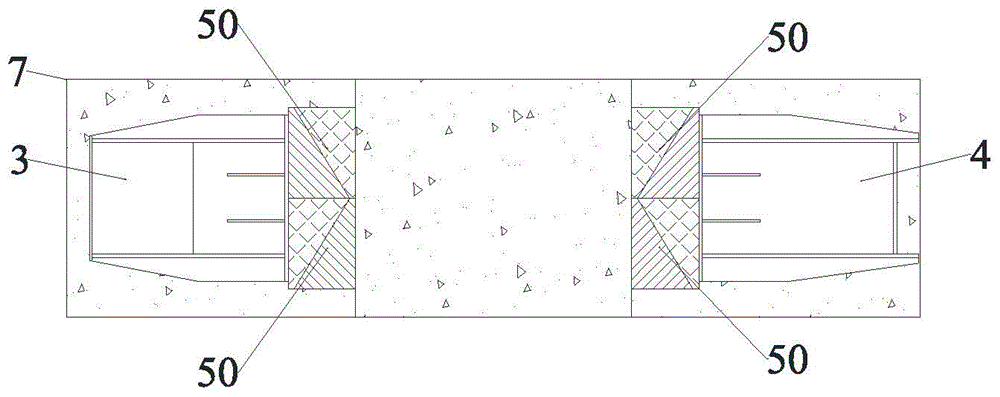

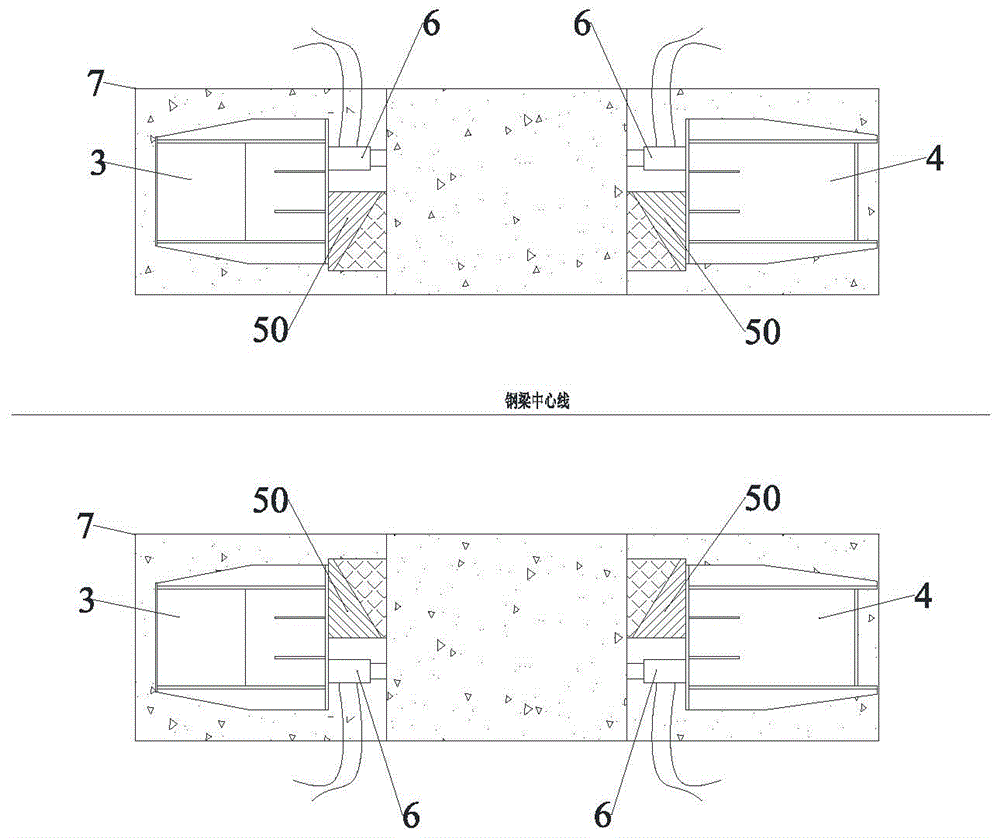

[0031] Step 1. Provide two convex bearing pad stones 7, the bearing pad stones 7 include a pad stone raised portion 71, the pad stone left side 72 and the pad stone right side 73, and each support pad stone 7 is erected A pair of steel beams 1, and the steel beams 1 are supported by jacks;

[0032] Step 2, install the support 2 on the upper surface of the raised part 71 of the support pad stone, and grout the support 2;

[0033] Step 3. After the strength of the support 2 reaches the design strength, place the two pairs of steel beams 1 on the corresponding support 2 res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com