Multi-objective Genetic Algorithm and rbf Neural Network Optimization Modeling Method for Coking Oven Pressure

A multi-objective genetic and neural network model technology, applied in the field of multi-objective genetic algorithm and RBF neural network optimization modeling, can solve the problems of difficult modeling process of coking furnace furnace pressure object, and achieve high accuracy and good dynamic characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Taking the coking furnace pressure as the actual object, taking the opening of the flue baffle as the input, and taking the coking furnace pressure as the output, the model of the coking furnace pressure is established.

[0033] The steps of the inventive method comprise:

[0034] Step 1. Collect the real-time operation data of the process and establish the RBF model of the process object. The specific steps are as follows:

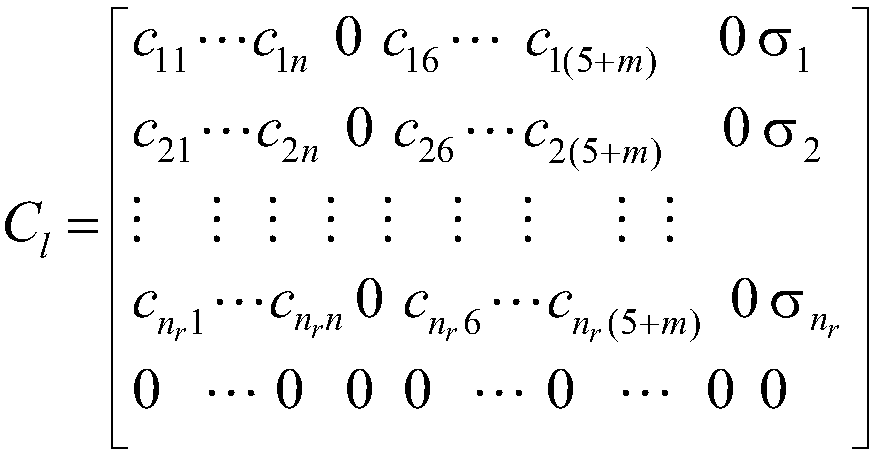

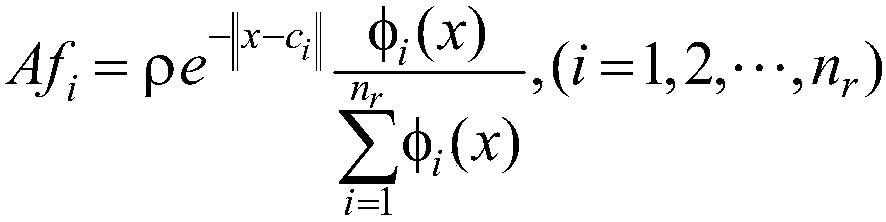

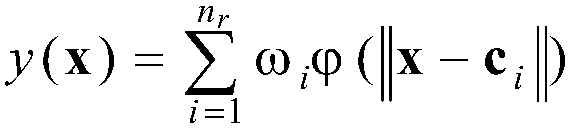

[0035] 1.1 From the RBF neural network structure including the input layer, output layer and hidden layer, the mapping relationship of the network is obtained, that is, the input and output model of the system, in the following form:

[0036]

[0037] Among them, x=(x 1 ,x 2 ,...,x n ) represents the n input node vector, y represents the output variable of the network, c i ∈ R n Represents the center vector of the i-th hidden layer neuron, R n is the Euclidean space, is a Gaussian function, ||x-c i || means x to c i The radial distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com