Organic light-emitting diode display having high aperture ratio and method for manufacturing the same

A light-emitting diode and display technology, applied in the direction of diode, semiconductor/solid-state device manufacturing, electric solid-state device, etc., can solve the problems of organic light-emitting diode display time and cost, increased defect generation rate, and reduced output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

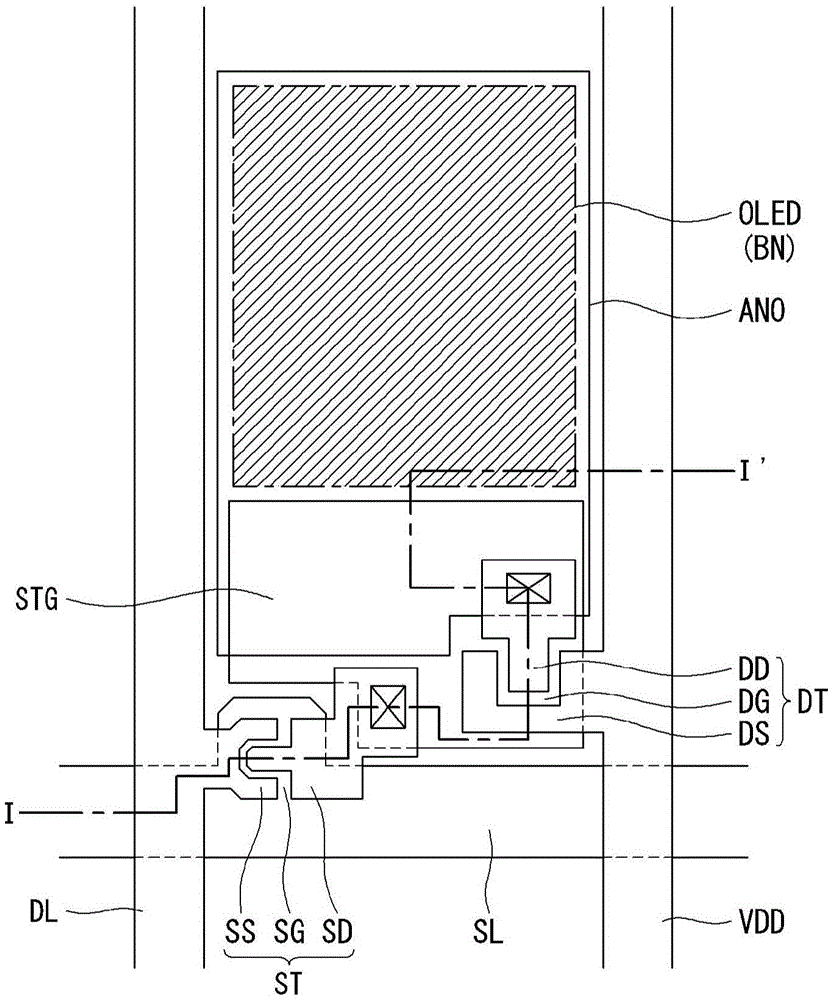

[0036] will refer to Figure 5 with Figure 6 A description is given of the organic light emitting diode display according to the first embodiment of the present invention. Figure 5 is a plan view illustrating the structure of an organic light emitting diode display according to a first embodiment of the present invention, Figure 6 is instantiated along the Figure 5 A cross-sectional view of the structure of the organic light emitting diode display according to the first embodiment of the present invention taken along the line II-II'.

[0037] refer to Figure 5 with Figure 6 , the organic light emitting diode display according to the first embodiment of the present invention includes: a substrate SUB in which a light-emitting area AA and a non-light-emitting area NA are defined; a switch TFTST; a driving TFTDT connected to the switch TFTST; Two storage capacitor electrodes SG2, the second storage capacitor electrode SG2 contact drive TFTDT; storage capacitor STG, the...

no. 2 approach

[0061] will refer to Figure 8 and Figure 9 A description is given of an organic light emitting diode display according to a second embodiment of the present invention. Figure 8 is a plan view illustrating the structure of an organic light emitting diode display according to a second embodiment of the present invention, Figure 9 is instantiated along the Figure 8 A cross-sectional view of the structure of the organic light emitting diode display according to the second embodiment of the present invention taken along the line III-III'.

[0062] refer to Figure 8 and Figure 9 , the organic light emitting diode display according to the second embodiment of the present invention includes: a substrate SUB in which a light-emitting area AA and a non-light-emitting area NA are defined; a switch TFTST; a first storage capacitor electrode SG1, the first storage capacitor The electrode SG1 is connected to the switch TFTST; the driving TFTDT is connected to the switch TFTST; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com