LED drive circuit based on constant-ON-time control

A constant on-time, LED-driven technology, applied in energy-saving control technology, lamp circuit layout, electric light source, etc., can solve the problems of switching frequency change, complex structure, large ripple, etc., to achieve fast response, small current ripple, large The effect of market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

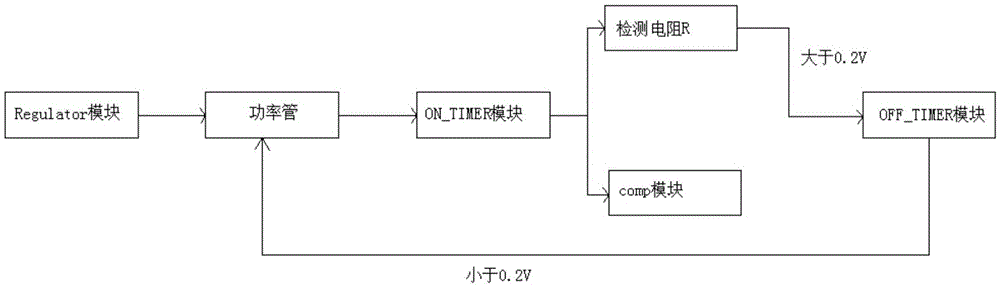

[0013] A specific embodiment of the present invention: an LED drive circuit based on constant on-time control, wherein the LED drive circuit includes a Regulator module, an ON_TIMER module, an OFF_TIMER module, a COMP module detection resistor R, and a power tube. When the system is powered on In an instant, the current passes through the Regulator module, so that it generates power inside and supplies power to each module, so that the drive circuit system starts to work; first, the power tube is turned on, and the turn-on time is set by the ON_TIMER module. At this time, the circuit flows through The current in the LED gradually increases. When the timing time is up, the power tube is turned off, and the off time is set by the OFF_TIMER. At this time, the current in the LED gradually decreases; when the timing time is up, the COMP module detects the If the voltage on the resistor R is higher than 0.2V, it will continue to be closed, and if the voltage is lower than 0.2V, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com