Small-sized hardware part image sorting machine

A technology of hardware parts and sorting machines, applied in sorting and other directions, can solve the problems of low positioning accuracy, affecting the detection effect, and poor overall effect, and achieve the effects of high positioning accuracy, guaranteed pass rate, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

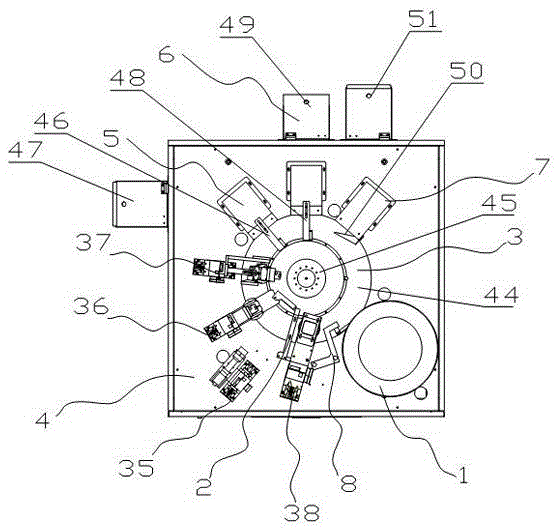

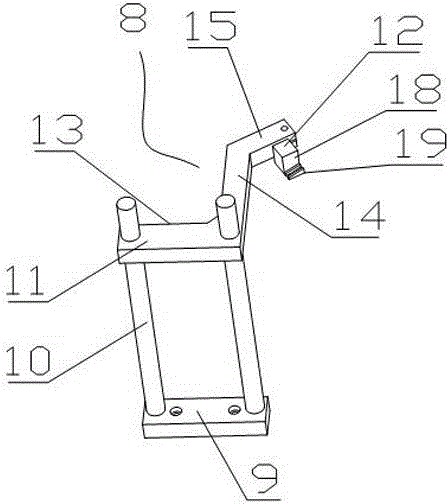

[0034] exist figure 1 , figure 2 In the shown embodiment, the image sorting machine for small hardware parts includes a vibration plate 1, a product positioning mechanism 2, a rotation detection mechanism 3, an image detection device 4, a qualified product separation mechanism 5, a defective product separation mechanism 6, and a suspected part separation mechanism. Mechanism 7 and control system, the vibrating plate 1 is connected with the rotation detection mechanism 3, the product positioning mechanism 2 is set on the station near the product entrance of the vibrating plate 1 and above the rotation detection mechanism 3, the qualified product separation mechanism 5, the defective product The separation mechanism 6 and the suspect part separation mechanism 7 are sequentially arranged on the station on the rear side of the product positioning mechanism 2 along the rotation direction of the rotation detection mechanism 3, and the image detection device 4 is arranged on the pro...

Embodiment 2

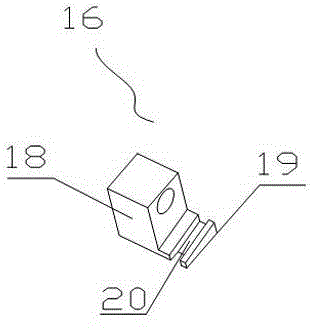

[0042] exist Figure 7 , Figure 8 , Figure 9 In the shown embodiment, the image sorting machine for small hardware parts is basically the same as Embodiment 1, the difference is that the micro-track 12 is a semi-closed micro-track 17, and the semi-closed micro-track 17 includes a track seat 18 and a wedge-shaped Track 19, the central position of wedge-shaped track 19 is provided with T-shaped track slot 21 along the length direction of wedge-shaped track ( Figure 10 ); the length of the wedge track 19 is less than 30 times the diameter of the part to be detected.

[0043] The inspection machine described in the above-mentioned embodiments guides the workpieces to be inspected from the vibrating disk to the rotating disk smoothly through a fixed dialing wheel or a guiding mechanism composed of a non-powered miniature guide rail mechanism, and evenly Spread it on the transparent turntable to realize the photographic detection and separation of workpieces, and achieve the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com