Manufacture and assembly technology of annular self-locking lifting hook

An assembly process and hook technology, which is applied in the field of manufacturing and assembly process of rigging ring-type self-locking hooks, can solve the problems of single production and manufacturing, inability to guarantee product quality and required product functions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with accompanying drawing.

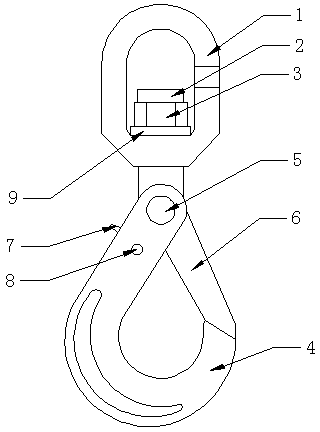

[0009] In the view, take the ring-type self-locking hook as an example: the precision casting process is used to cast the ring 1, the hook body 4, the hook body 6, the hook lock block 7 rough parts - eliminate the ring 1, the hook body 4, the hook Hook body 6, hook lock block 7 blank casting internal stress—hanging ring 1, hook body 4, hook body 6, hook lock block 7, cleaning dirt, grinding to remove casting burrs and sharp corners—hanging ring 1, hook body 4, Hook body 6, hook lock block 7 drilling—hook bolt 2 sets of external threads—hanging ring 1, hook body 4, hook body 6, hook lock block 7 Surface polishing, degreasing, rust removal, phosphating —Spray the surface of ring 1, hook body 4, hook body 6, and hook lock block 7 with yellow electrostatic powder—Use No. 45 round steel to turn connecting shaft 5 and lock block shaft 8 on a lathe—connection shaft 5 and lock bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com