Spectacle lens coating cleaning equipment and method

A technology for cleaning equipment and spectacle lenses, which is applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., and can solve the problem that spectacle lenses are susceptible to large vibrations or shakes, rough manual cleaning methods, and cleaning problems. Problems such as poor process stability, to achieve the effect of highlighting substantive features, good cleaning effect, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below according to the drawings and embodiments.

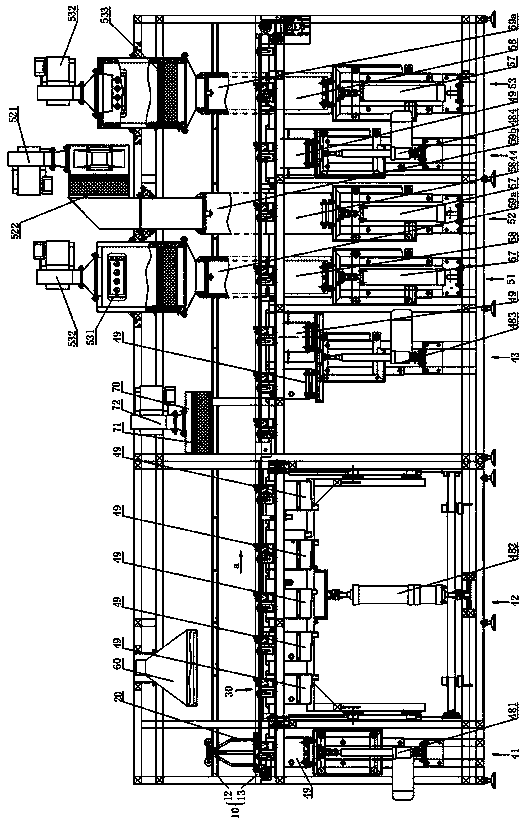

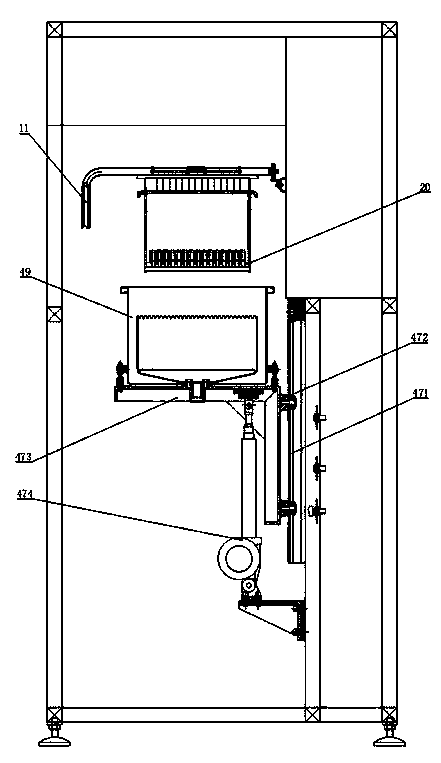

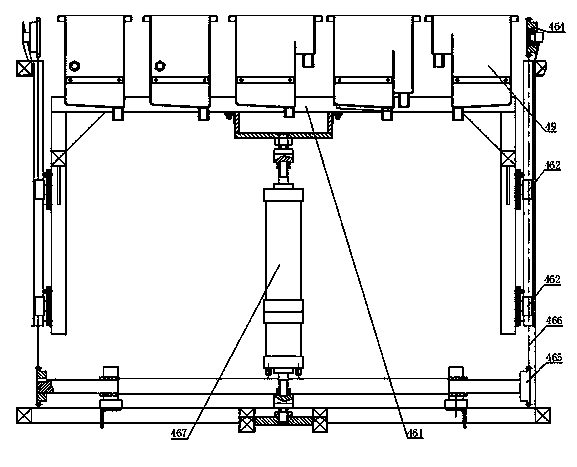

[0033] Such as figure 1 , Figure 8 As shown, the spectacle lens coating processing and cleaning equipment described in the embodiment of the present invention includes a delivery guide rail 10 and a washing basket 20 that moves smoothly and intermittently along the delivery guide rail 10. The delivery track 10 is provided with an intermittent positioning station 30. The direction of movement a, the corresponding intermittent positioning station 30 is provided with a liftable ultrasonic cleaning device and a movable air drying device; Cleaning machine 49, the ultrasonic cleaning machine 49 below of each cleaning unit is fixedly connected with lifting device; Drying warehouse 58.

[0034] During the cleaning work, the spectacle lens is installed in the washing basket, and the washing basket performs a steady intermittent movement. When passing through each proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com