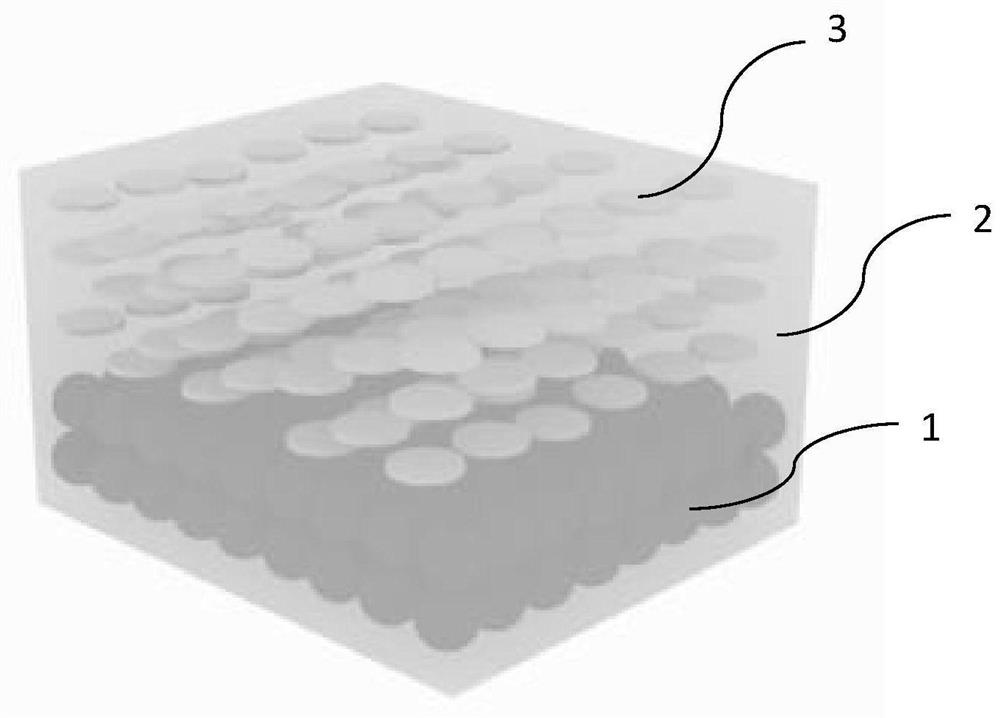

Epoxy composite material with heterostructure and preparation method thereof

A composite material, heterogeneous structure technology, applied in the direction of epoxy resin glue, adhesive type, adhesive additive, etc. Good thermal conductivity, increased electromagnetic shielding properties, increased electrical insulation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing an epoxy composite material with a heterogeneous structure of heat conduction, heat storage and electromagnetic shielding properties, comprising the following steps:

[0032] S1. Modification of low-melting-point alloys: Mix ethanol and chloroform at a mass ratio of 1:1.5 to obtain a mixed solution of ethanol-chloroform, and mix the low-melting-point alloy SnBi with a particle size of 30 μm 17 Cu 0.5 Add it into the ethanol-chloroform mixed solution together with propyl methylphosphoric acid, take it out after soaking for 28 hours, and place it in a new ethanol-chloroform mixed solution for 15 minutes to remove excess modifier.

[0033]S2. Modification of insulating inorganic filler: mix absolute ethanol and Tris-HCl solution buffer solution according to the volume ratio of 1:1.5, add 4g of silicon nitride with a particle size of 15μm and ultrasonically treat for 40min to disperse, and adjust the pH value of the suspension If it is 9.0, add 0.12g...

Embodiment 2

[0038] The preparation method is the same as in Example 1, the difference is that 8.8g of modified SnBi is weighed in step S4 17 Cu 0.5 (particle size is 30 μm), as a comparative example of Example 1, an epoxy composite material 2 with a heterogeneous structure was prepared.

Embodiment 3

[0040] The preparation method is the same as that of Example 1, except that 0.48 g of modified silicon nitride is weighed in step S4 as a comparative example of Example 1 to prepare the epoxy composite material 3 with heterogeneous structure.

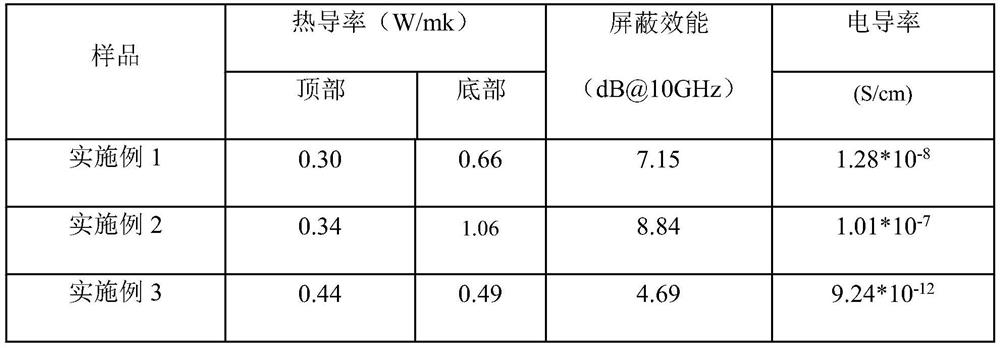

[0041] The thermal conductivity of table 1 embodiment 1, 2 and 3, the comparison of electric insulation performance and shielding effectiveness

[0042]

[0043] As can be seen from the data in Table 1, comparing Example 1 and Example 2, under the condition that the content of modified carbon nitride is constant, as the modified SnBi 17 Cu 0.5 As the content increases, the thermal conductivity of the bottom of the epoxy composite material is greatly improved, so it can be modified by changing the SnBi 17 Cu 0.5 The amount of addition can be used to control the thermal conductivity of the bottom of the epoxy composite material. Comparative example 1 and embodiment 3, in modified SnBi 17 Cu 0.5 When the content remains unchanged, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com