Three-floating-sucker structure

A suction cup and component technology, applied in the directions of manipulators, chucks, manufacturing tools, etc., can solve the problems of falling, insufficient grasping force of a single suction cup manipulator, high grasping positioning requirements, etc., achieving reasonable position, easy grasping positioning, Strong gripping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

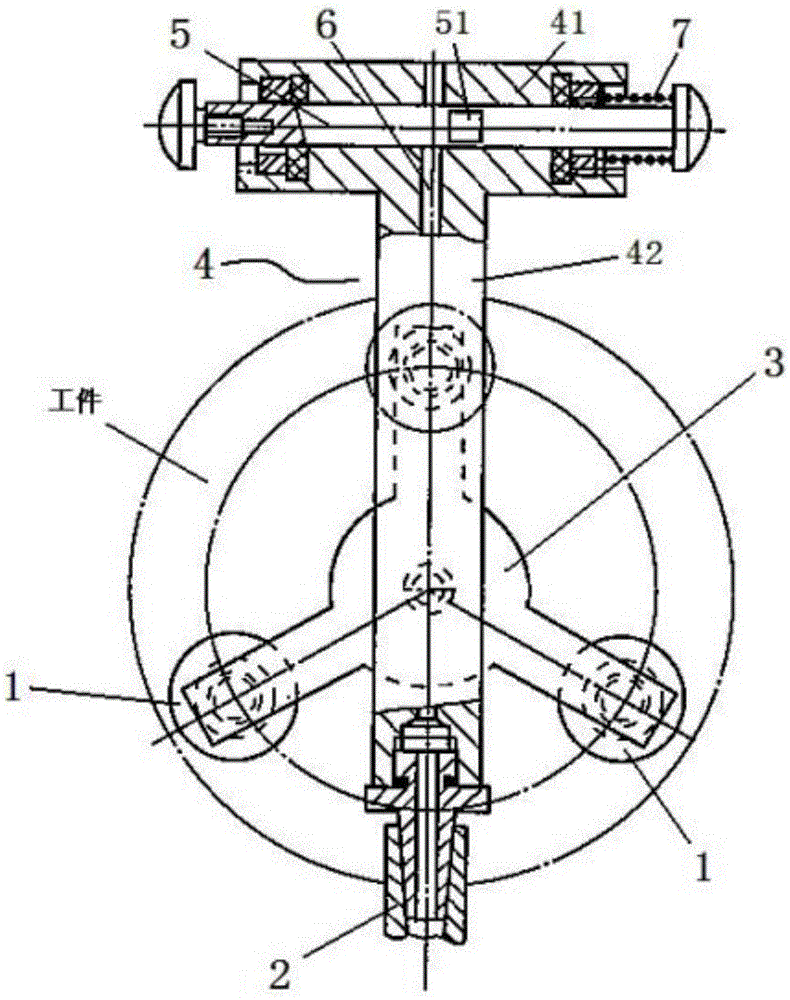

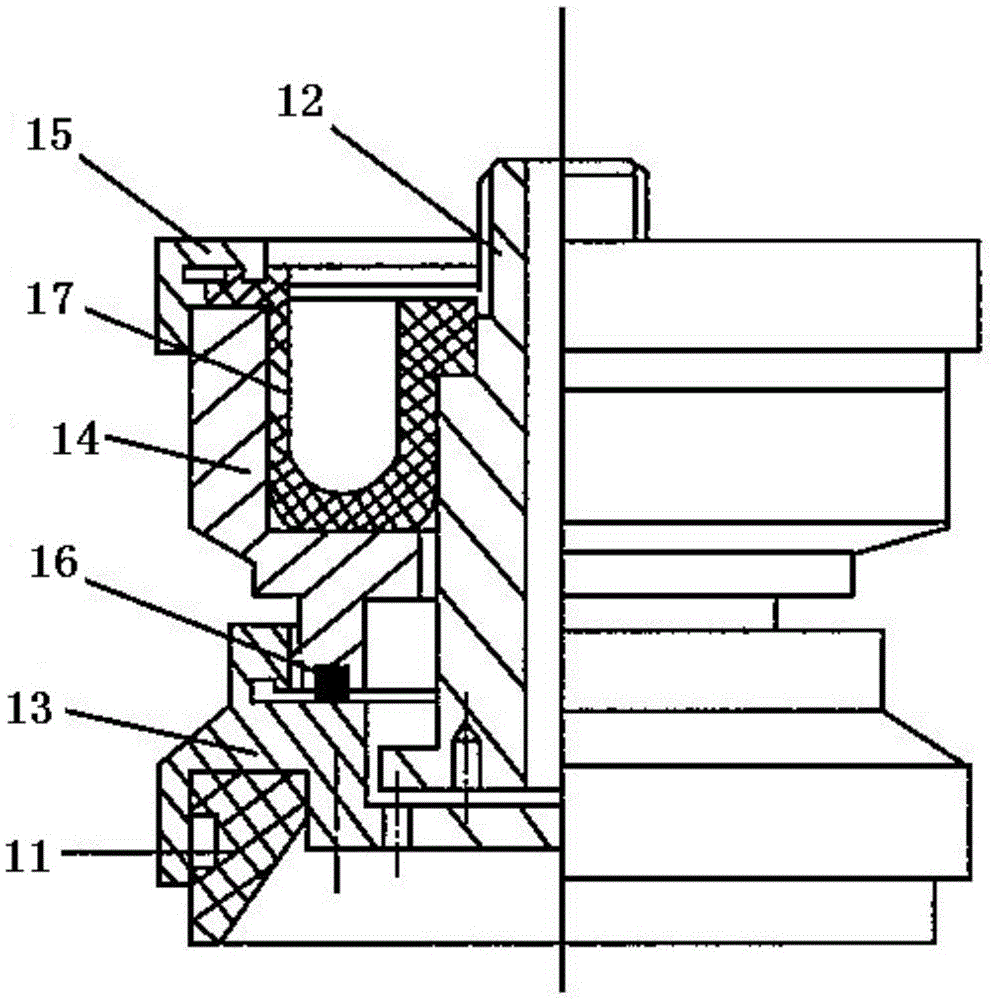

[0016] Such as figure 1 , figure 2 As shown, a three-floating suction cup structure includes a floating suction cup 1, a vacuum pump suction head 2, a suction cup bracket 3, a valve body 4, and a push rod 5. The valve body 4 is set as a T-shaped structure, including a horizontal assembly 41, a vertical Assembly 42, the vertical assembly 42 is provided with a ventilation groove 6, and the ventilation groove 6 runs through the middle of the horizontal assembly 41; the vacuum pump suction head 2 is connected with the free end of the vertical assembly 42; the push rod 5 moves Socketed in the horizontal assembly 41, the push rod 5 is provided with a through hole 51; the bottom surface of the vertical assembly 41 is provided with a suction cup bracket 3; the floating suction cup 1 is set to three, and the free end of the suction cup bracket 3 is provided with three A floa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com