Automatic concrete chiseling equipment of prefabricated bridge hollow slab web and construction method

A technology of hollow slabs and concrete, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problem that the uniformity, roughness, depth, and exposure of chiseling are difficult to meet the requirements, which affects the transfer of beams and slabs and the use of prefabricated pedestals for beams and slabs. rate, endangering the physical and mental health of operators, etc., to achieve the effects of controllability and adaptability, reducing labor and material waste, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

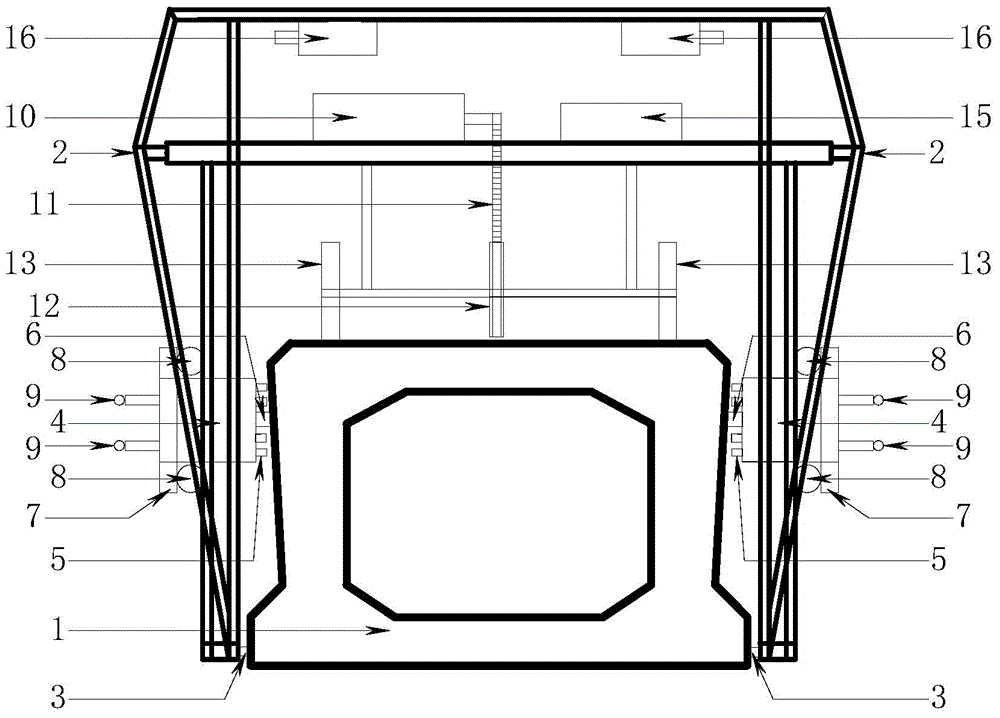

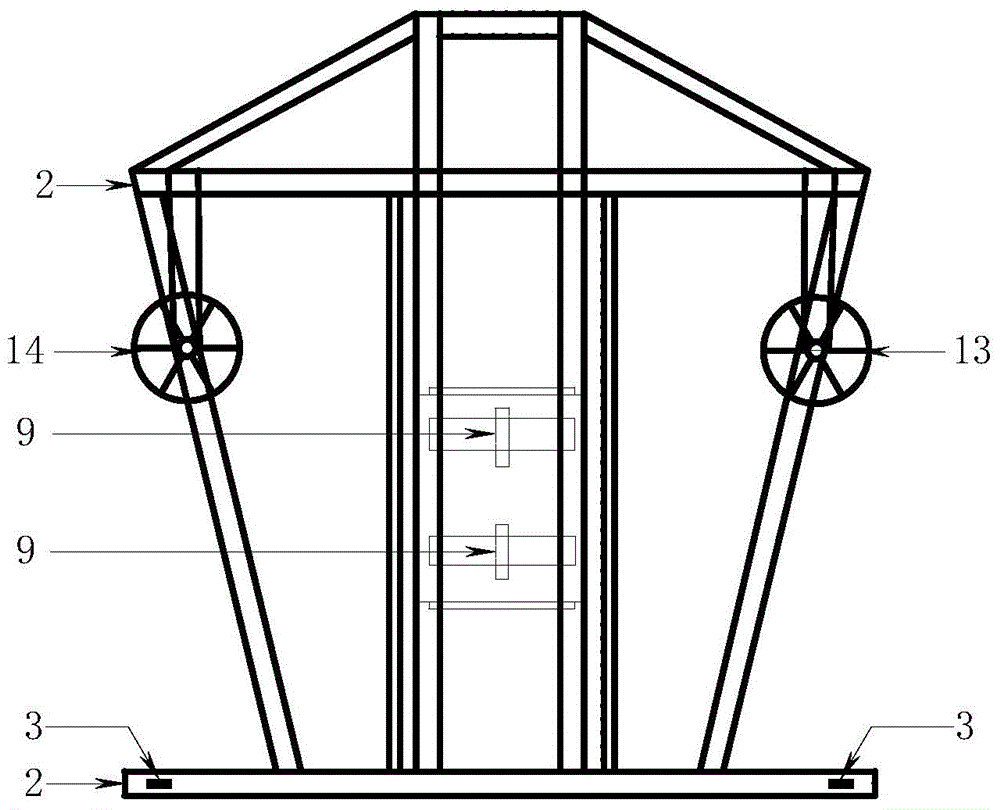

[0033] A kind of equipment for automatic roughening of bridge prefabricated hollow slab web concrete, such as figure 1 and 2 As shown: it includes a carrying frame 2 driven by a walking device. The bottom of the carrying frame 2 is provided with a positioning wheel 3. On both sides of the carrying frame 2, there are two small steel wheels 8 that are controlled by the control device along the above-mentioned carrying frame. 2 The chiseling device can move vertically up and down on both sides, and the control device is driven by a power device;

[0034] The carrying frame 2 is welded by two different types of channel steel, and four positioning wheels 3 are respectively installed at the ends of the channel steel on both sides of the left and right sides of the carrying frame 2;

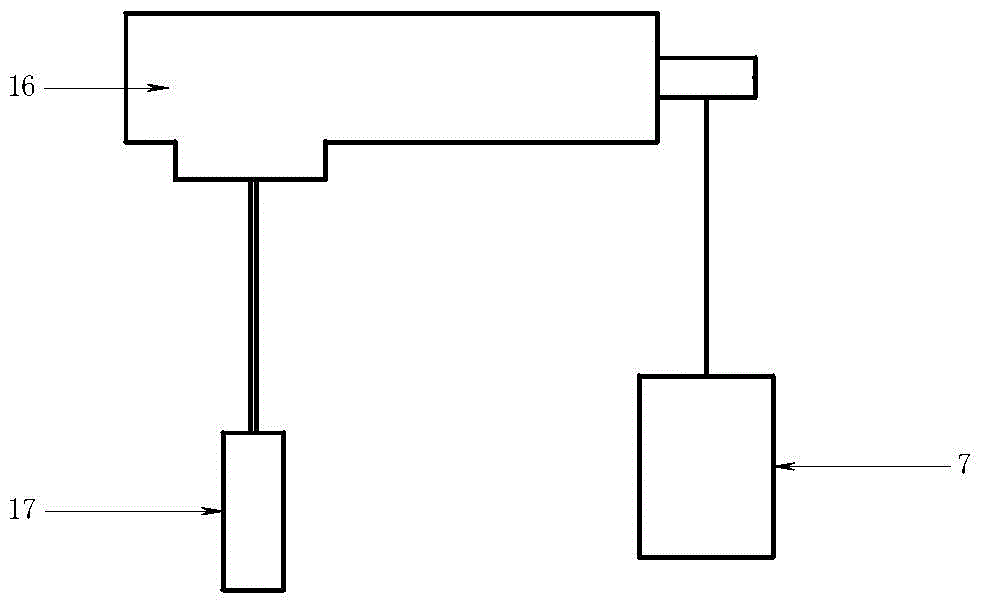

[0035] like Figure 5 and 6 Shown: the chisel device includes a chisel bracket 7 fitted on a small steel wheel 8, a chisel 4 with a chisel head 5 is fixed on the bracket 7, and at the end of the chis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com