Environment-friendly weather-resistant and stain-resistant wallpaper and making method

A production method and wallpaper technology, applied to chemical instruments and methods, household walls, water pollutants, etc., to achieve the effects of environmentally friendly, safe and efficient production process, simple production process, safe and environmentally friendly production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

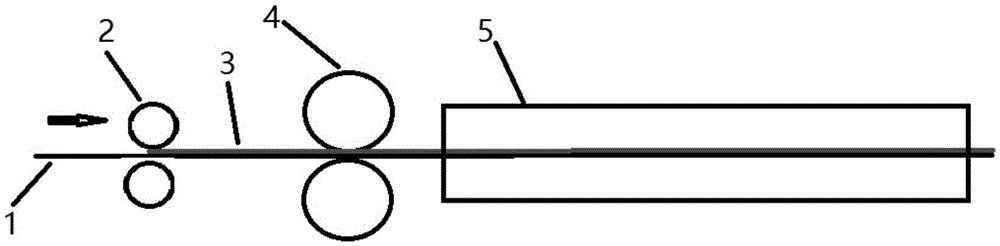

Method used

Image

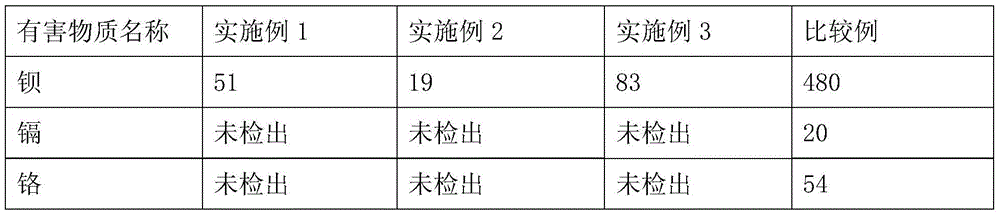

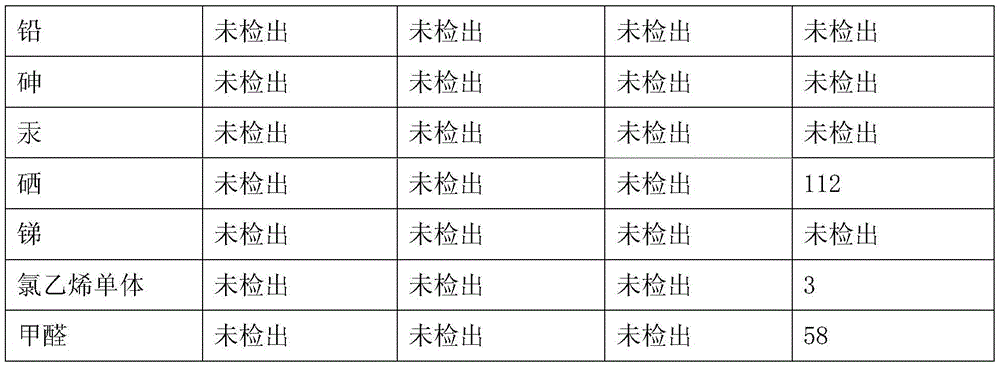

Examples

Embodiment 1

[0043] An environment-friendly, weather-resistant and stain-resistant wallpaper in this embodiment includes a substrate layer and a silicone rubber layer that are compositely connected together. The thickness of the silicone rubber layer is 0.1-1mm.

[0044] The base material layer is paper embryo, woven cloth or other roll materials.

[0045] The silicone rubber layer is formed by disposing silicone rubber on the substrate layer, and the silicone rubber includes vinyl polysiloxane raw rubber, filler, structure control agent, masticating agent, hydrogen-containing silicone oil, platinum catalyst and retarders.

[0046] The vinyl polysiloxane raw rubber is a polysiloxane in which at least two vinyl groups are directly linked to Si, and wherein the chain end or side chain of the polysiloxane contains a vinyl group, or the chain end and the side chain simultaneously contain vinyl. The vinyl polysiloxane raw rubber has a molecular weight of 550,000-800,000 and a vinyl content o...

Embodiment 2

[0073] The difference between this embodiment and embodiment 1: the raw material of organosilicon rubber material adopts the following components and mass ratio:

[0074] Vinyl polysiloxane raw rubber: 50KG of vinyl polysiloxane raw rubber with a molecular weight of 800,000 and a vinyl content of 0.1%, 50KG of a vinyl polysiloxane raw rubber with a molecular weight of 800,000 and a vinyl content of 1%

[0075] Filler: white carbon black (A200) 40KG

[0076] Structure control agent: short-chain hydroxyl silicone oil 4.5KG

[0077] Plasticizing agent: glyceryl stearate 0.25KG

[0078] added after mixing

[0079] Hydrogen-containing silicone oil (hydrogen content 1.6%, viscosity 50) 5.5KG

[0080] Delay agent: methyl butynol 0.007KG

[0081] Platinum catalyst (30000ppm) 0.035KG

[0082] Color paste 5KG

[0083] Functional additives: antifungal agent 0.5KG antibacterial agent 0.1KG made into silicone material

[0084] Another difference between this embodiment and embodimen...

Embodiment 3

[0086] The difference between this embodiment and embodiments 1 and 2: the raw material of organosilicon rubber material adopts the following components and mass ratio:

[0087] Vinyl polysiloxane raw rubber: 50KG of vinyl polysiloxane raw rubber with a molecular weight of 600,000 and a vinyl content of 0.05%, 50KG of a vinyl polysiloxane raw rubber with a molecular weight of 600,000 and a vinyl content of 0.5%

[0088] Filler: Precipitated white carbon black (specific surface area 200) 60KG

[0089] Structure control agent: short-chain hydroxyl silicone oil 4.5KG

[0090] Plasticizing agent: glyceryl stearate 0.25KG

[0091] added after mixing

[0092] Hydrogen-containing silicone oil (hydrogen content 1.6%, viscosity 50) 4KG

[0093] Retardant: Ethynyl cyclohexanol 0.007KG

[0094] Platinum catalyst (30000ppm) 0.035KG

[0095] Color paste 5KG

[0096] Functional additives: antifungal agent 0.5KG made into silicone material

[0097] Another difference between this embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com