A kind of transfer type laser embossing polyester film and preparation method thereof

A polyester film and transfer type technology, applied in the field of polyester film, can solve the problems of complex process of transfer type laser imprinting polyester film, coating uniformity, coating solvent pollution, etc., and achieve important market value and promotion The effect of application value, improving product quality and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

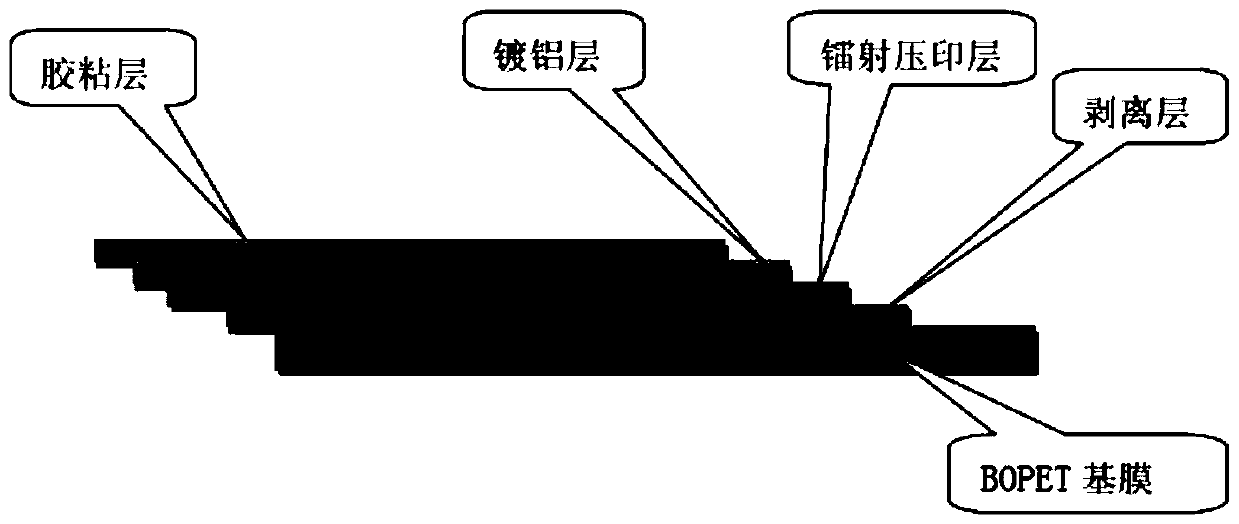

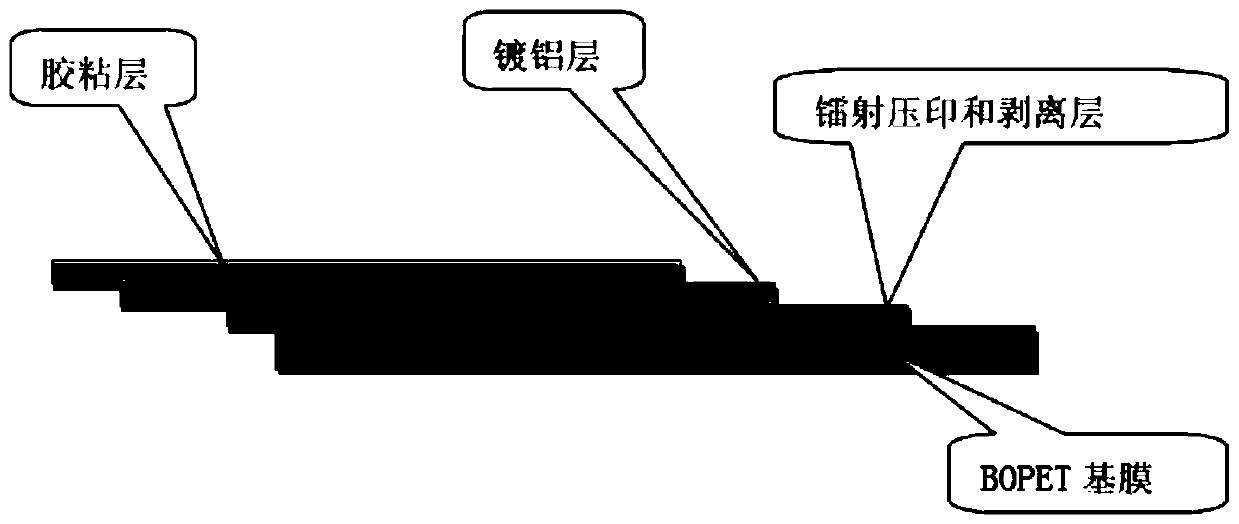

[0037] A transfer type laser embossed polyester film (or laser transfer embossed film), its film structure is a three-layer co-extruded composite structure, such as Figure 4 Shown: The new polyester film has a three-layer layered structure, and its upper surface layer is made of amorphous PET polyester, SiO 2 Transfer-type laser imprinting layer formed by additive-type PET polyester and polysiloxane release agent; transfer-type laser imprinting layer is directly co-extruded and compounded with PET polyester homopolymer, SiO 2 The core layer of additive-type PET polyester; the other surface of the core layer is directly co-extruded and compounded with PET polyester homopolymer, SiO 2 Lower skin layer of additive PET polyester.

[0038] The new polyester film is produced by a co-extrusion biaxial stretching process.

[0039]The sources of raw materials used in the following are: Amorphous PET polyester chips were purchased from Eastman, USA, model Easter6763; PET polyester ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com