Top ring type vertical paddle wheel

A technology of paddle wheels and top rings, applied in the direction of rotary propellers, etc., can solve the problems of low efficiency, increase of paddle wheel rotation resistance, weakening of paddle wheel driving force, etc., and achieve simple structure, low precision requirements, and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

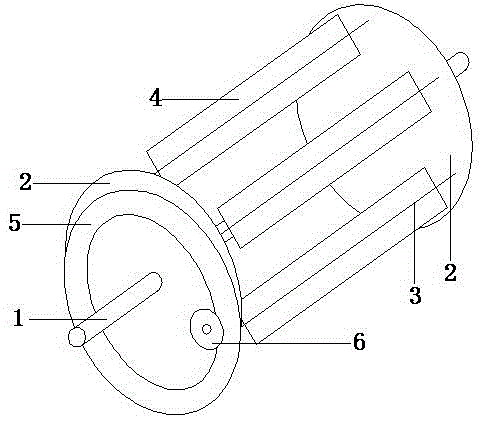

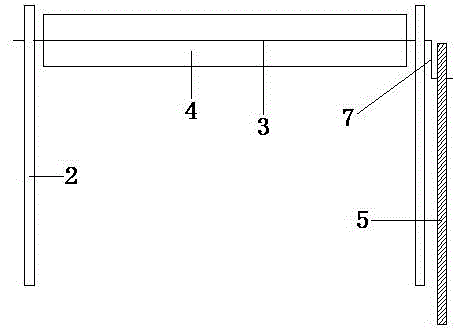

[0015] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes two wheels 2 symmetrically connected by a rotating shaft 1, and a number of uniformly distributed paddles 4 are connected between the two wheels 2 through a movable shaft 3, and the outer side of one of the wheels 2 is provided with a steering The steering ring 5 is meshed with the sheave 6 installed on the hull, and the steering ring 5 is connected with the movable shaft 3 through the connecting rod 7; the rotating shaft 1 is connected to the power unit; the steering ring 5 is hollow inside Ring disk.

[0016] When the vertical paddle wheel of the present invention is in operation, the power device provides power, and the rotating shaft 1 drives the wheel disc 2 to rotate, and the paddles 4 on the wheel disc 2 fluctuate the water flow to realize the operation of the hull; during the operation of the hull, the sheave 6 is fixed on the hull , and the position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com