Marine telescopic crane

A crane and marine technology, applied in the field of marine telescopic cranes, can solve problems such as inconvenient lifting of cargo, failure of cranes to work normally, and affecting work efficiency, and achieve the effects of preventing wear and tear of steel wire ropes, good lubrication, and optimized shape and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

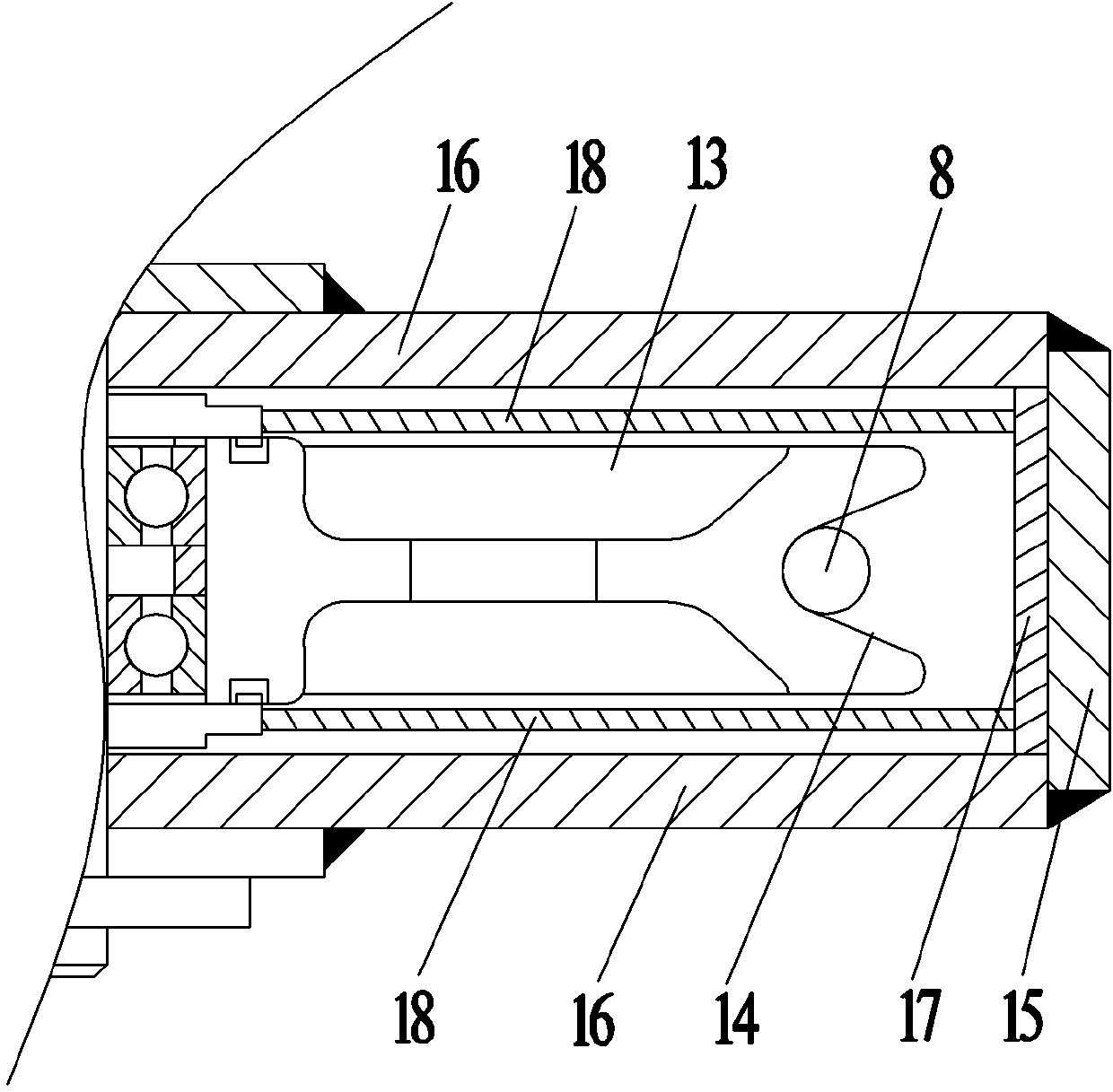

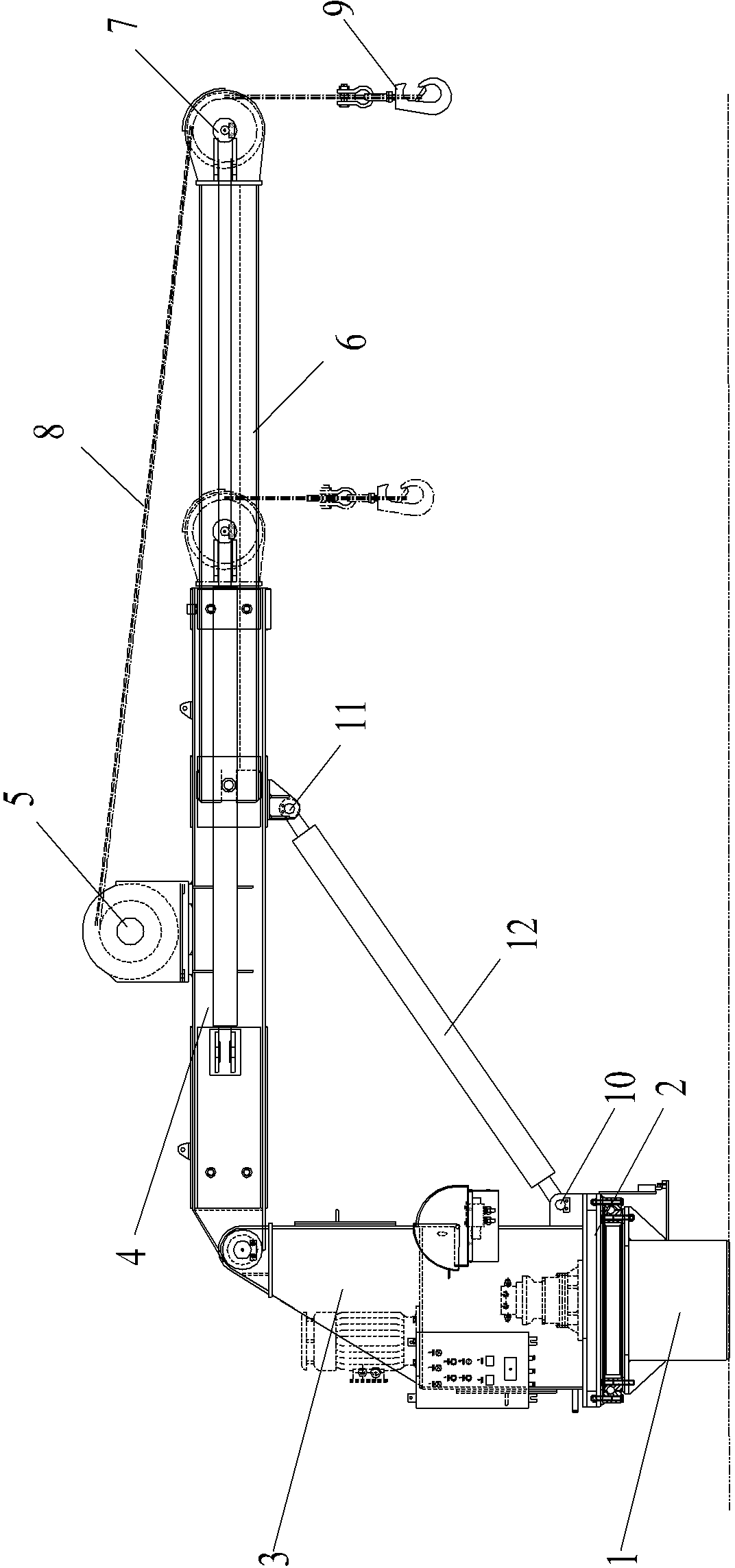

[0009] like figure 1 , figure 2 As shown, the present invention includes a base 1 fixed on the deck, a tower body 3 is installed on the base 1 through a slewing support 2, a basic arm 4 is hinged on the top side of the tower body 3, and a hydraulic winch is installed on the upper end of the basic arm 4 5. A retractable telescopic arm 6 is installed inside the basic arm 4, and a pulley device 7 is installed at the end of the telescopic arm 6. One end of the wire rope 8 is connected to the hydraulic winch 5, and the other end of the wire rope 8 passes through the pulley device 7 to connect to the hook 9. A first fixture 10 is provided on the lower side of the tower body 3, a second fixture 11 is provided on the bottom of the basic arm 4, and a luffing cylinder 12 is installed between the first fixture 10 and the second fixture 11. Lifting conditions with different working radii can be achieved through the telescopic boom 6. After the operation is completed, the telescopic boom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com