Concentrated detergent and preparation method thereof

A cleaning agent and additive technology, applied in the field of concentrated cleaning agent and its preparation, to achieve the effects of unique formula, strong decontamination ability, and wide source of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

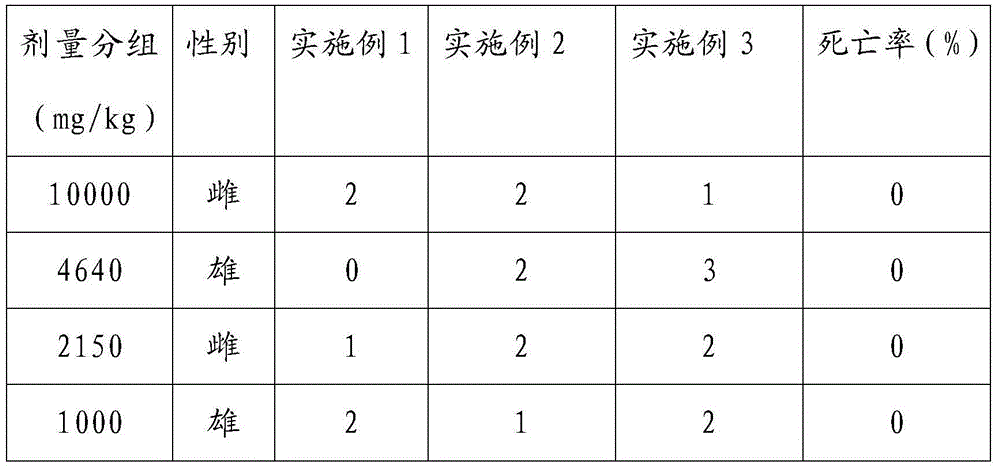

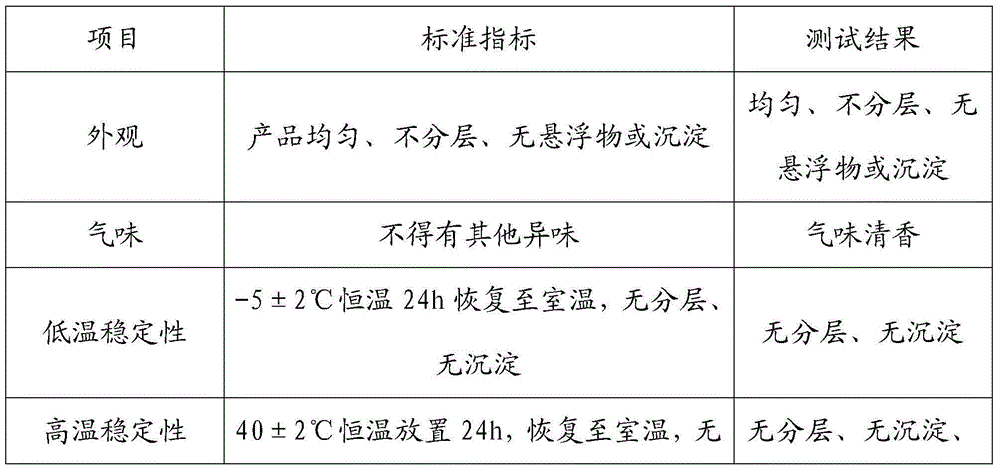

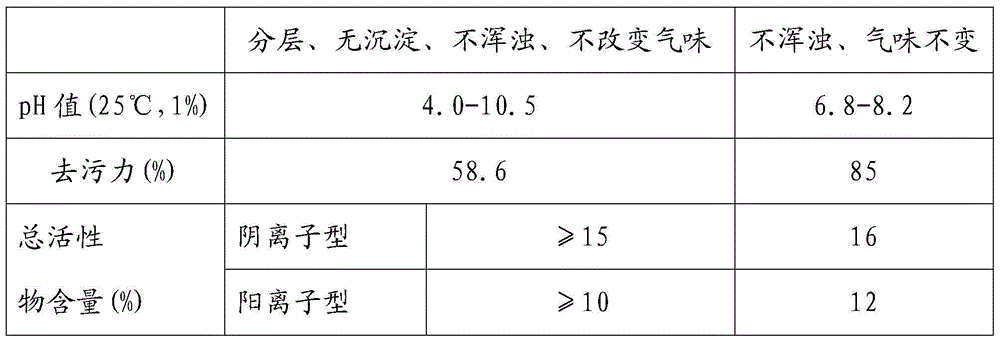

Examples

Embodiment 1

[0023] A concentrated cleanser, made of the following raw materials in parts by weight: 80 parts of coconut oil derivatives, 50 parts of citrus extracts, 15 parts of saponin powder, 10 parts of Sapinberry extracts, 6 parts of perilla extracts, 8 parts of lilac extract, 2 parts of cnidium fruit extract, 2 parts of alcohol ethoxylate, 0.4 parts of propylene glycol, 1 part of sodium citrate, 4 parts of sea salt, 2 parts of antistatic agent, 4 parts of anionic surfactant, auxiliary 3 parts of agent, 110 parts of deionized water.

[0024] The preparation method of above-mentioned concentrated cleaning agent, comprises the following steps:

[0025] (1) Mix coconut oil derivatives, citrus extracts and saponins powder with deionized water into a container, stir for 10 minutes at a temperature of 50-60°C and a speed of 4000 rpm, and then add The sub-extract, perilla, lilac extract and cnidium extract are stirred and emulsified for 20min at a temperature of 50°C and a rotation speed of...

Embodiment 2

[0029]A concentrated cleanser, made of the following raw materials in parts by weight: 120 parts of coconut oil derivatives, 75 parts of citrus extracts, 25 parts of saponin powder, 18 parts of Sapinberry extracts, 10 parts of perilla extracts, 18 parts of lilac extract, 8 parts of cnidium extract, 6 parts of alcohol ethoxylate, 1.8 parts of propylene glycol, 5 parts of sodium citrate, 9 parts of sea salt, 8 parts of antistatic agent, 15 parts of anionic surfactant, auxiliary 10 parts of agent, 160 parts of deionized water.

[0030] The preparation method of above-mentioned concentrated cleaning agent, comprises the following steps:

[0031] (1) Mix coconut oil derivatives, citrus extracts, saponins powder and deionized water into a container, stir for 15 minutes at a temperature of 60°C and a rotation speed of 5000 rpm, and then add Sapindus to extract extracts, perilla, lilac extracts and cnidium extracts, stirred and emulsified for 30min at a temperature of 60°C and a rota...

Embodiment 3

[0035] A concentrated cleaning agent, made of the following raw materials in parts by weight: 110 parts of coconut oil derivatives, 60 parts of citrus extracts, 21 parts of saponin powder, 16 parts of Sapinberry extracts, 8 parts of perilla extracts, 15 parts of clove extract, 5 parts of cnidium fruit extract, 4 parts of alcohol ethoxylate, 0.8 parts of propylene glycol, 3 parts of sodium citrate, 7 parts of sea salt, 5 parts of antistatic agent, 10 parts of anionic surfactant, auxiliary agent 6 parts, 140 parts of deionized water.

[0036] The preparation method of above-mentioned concentrated cleaning agent, comprises the following steps:

[0037] (1) Mix coconut oil derivatives, citrus extracts, saponins powder and deionized water into a container, stir for 15 minutes at a temperature of 55°C and a rotation speed of 4500 rpm, then add Sapindus chinensis extract Extracts, perilla, lilac extract and cnidium extract, at a temperature of 55°C and a rotation speed of 6000rpm, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com