Stretch-proof and shrinkage-resistant braid and processing method thereof

A stretch-resistant and webbing technology, used in fabrics, textiles, textiles and papermaking, etc., can solve the problems of weakened elasticity, poor recovery force, loose roots and loss of elasticity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

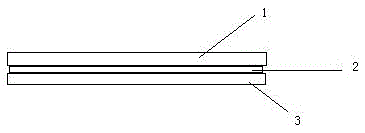

[0018] Such as figure 1 As shown, the stretch-resistant and shrink-resistant webbing disclosed in the present invention includes an upper layer 1, a lower layer 3, and a middle layer 2. The upper layer is made of warp and weft interwoven at a 1:1 interlacing ratio to form a staple fiber elastic fabric surface The lower layer is formed by interweaving warp and weft at a 1:2 interweaving ratio to form a long-fiber elastic woven surface, and the middle layer is formed by interweaving ultra-fine elastic fibers as warp yarns and ultra-fine straight fibers as weft yarns, and each interval The 6 warp threads are blended with a low-melting hot-melt covering yarn to wrap the roots. The warp threads in the upper and lower layers are superfine elastic fibers, and the weft threads are superfine stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com