Clothes treating apparatus with heat pump cycle

A technology of clothes treatment device and heat pump cycle, which is applied to washing devices, other drying devices, household appliances, etc., can solve the problems of evaporator dehumidification performance limitation, increase extra cost, etc., so as to improve dehumidification performance, improve performance and reliability. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

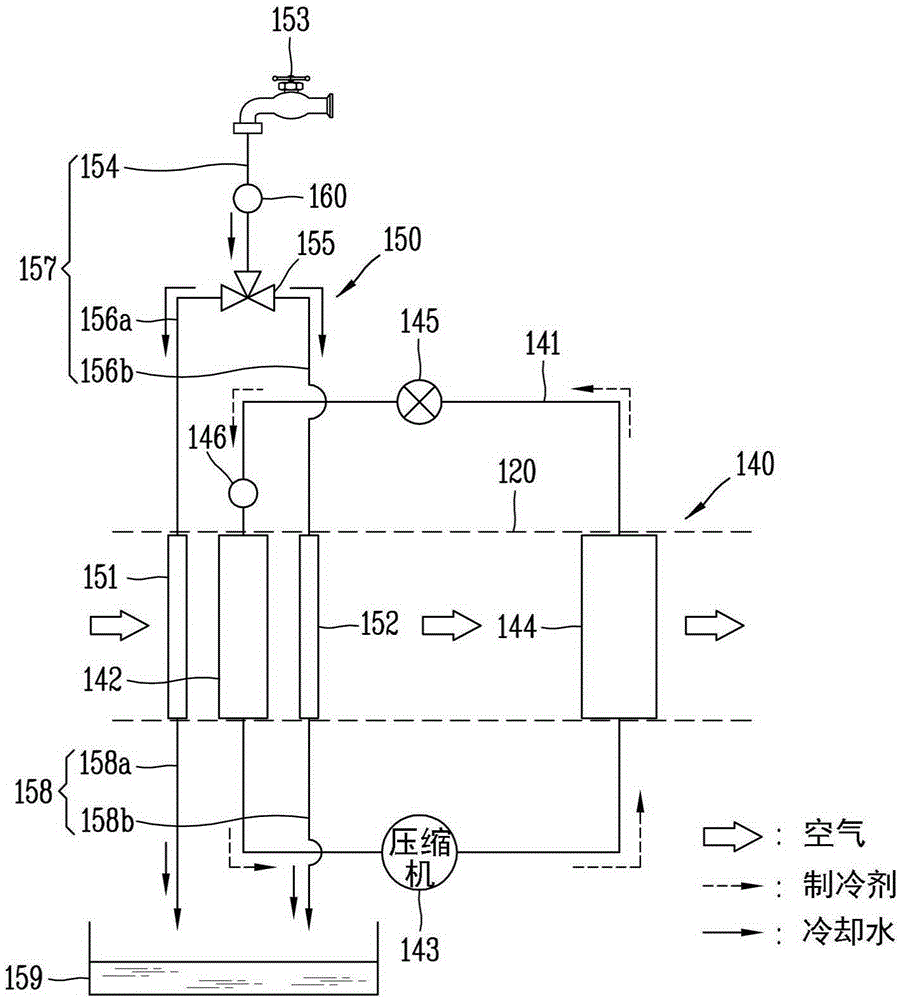

[0076] image 3 It is a schematic diagram showing the dehumidification system 150 of the first embodiment of the present invention.

[0077] The heat exchanger of the first embodiment is a water-cooled heat exchanger. The water-cooled heat exchanger may be a finned tube heat exchanger.

[0078] image 3 The illustrated plurality of heat exchangers may be constituted by a first water-cooled heat exchanger 151 arranged on the upstream side of the evaporator 142 and a second water-cooled heat exchanger 152 arranged on the downstream side of the evaporator 142 .

[0079] The dehumidification system 150 may include: a water supply unit 153, which supplies water to the first water-cooled heat exchanger 151 and the second water-cooled heat exchanger 152; a water supply pipe 157, which forms a water supply flow path to supply water to each heat exchanger respectively; The pipe 158 forms a drain flow path for draining water from each heat exchanger.

[0080] The water supply unit 1...

no. 2 example

[0095] Figure 4 It is a schematic diagram showing the dehumidification system of the second embodiment of the present invention.

[0096] Figure 4 The shown first water-cooled heat exchanger 251 and second water-cooled heat exchanger 252 are connected via a first connecting pipe 261 . The other end of the first distribution pipe 256a branched from the main water supply pipe 254 is connected to the image 3 The illustrated first distribution pipe 156a is differently connected to the downstream side of the first connection pipe 261 (based on the cooling water moving direction). One drain pipe 258 is connected to the first water-cooled heat exchanger 251 . Other structural elements are the same as or similar to those of the first embodiment, and therefore, detailed descriptions are omitted for clarity of description.

[0097] The movement path of the cooling water according to the temperature of the supplied water in the second embodiment will be described.

[0098]When th...

no. 3 example

[0101] Figure 5 It is a schematic diagram showing the dehumidification system of the third embodiment of the present invention.

[0102] Figure 5 The shown first water-cooled heat exchanger 351 and second water-cooled heat exchanger 352 are connected via a second connecting pipe 361 . The water supply pipe 357 is not composed of image 3 The shown main water supply pipe 154 , distribution pipes, etc. are constituted, and are directly connected to the first water-cooled heat exchanger 351 . Also, the drain pipe 358 may be connected only to the second water-cooled heat exchanger 352 . In this case, the first temperature sensor may be omitted.

[0103] The cooling water movement path and the action of the cooling water in the third embodiment will be described.

[0104] Cooling water flows into the first water-cooled heat exchanger 351 through the water supply pipe 357, and in the first water-cooled heat exchanger 351, the sensible heat and latent heat of the air to flow i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com