A Smooth and Soft Technology of Cotton Wool Blended Fabric

A technology of blended fabrics and cotton-wool, applied in the field of cotton-wool blended fabrics, can solve problems such as hardening of hand feeling and decrease of smoothness, and achieve the effects of improving softness, increasing bonding degree, and improving washing fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

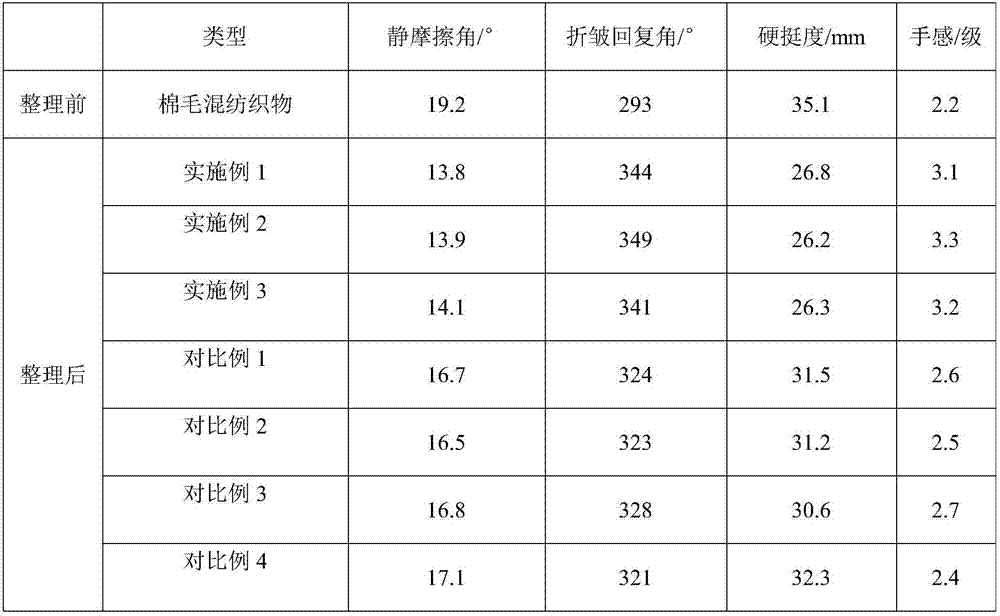

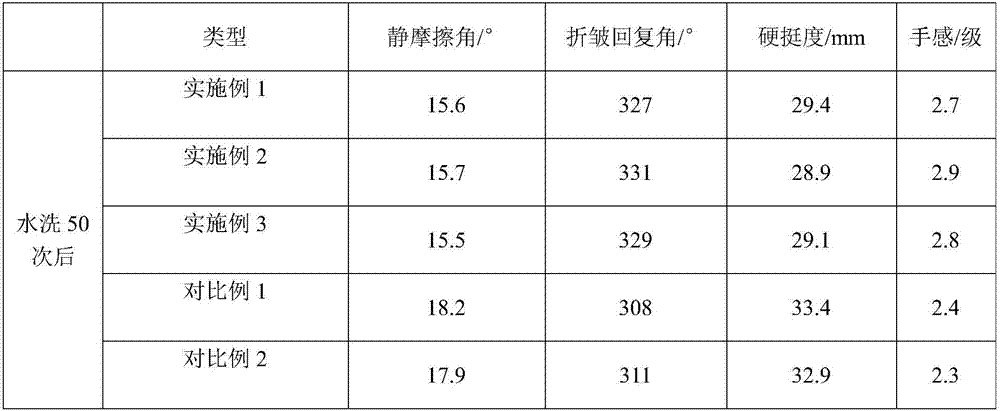

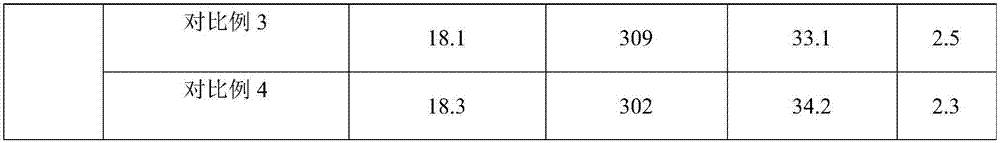

Examples

Embodiment 1

[0028] The present embodiment provides a cotton-wool blended fabric and its smooth and soft process, which comprises the following steps:

[0029] S1. Put the cotton-wool blended fabric in an environment with a temperature of 50°C and an ultrasonic power of 250W for 0.5h;

[0030] S2. Dry the cotton-wool blended fabric after ultrasonication in step S1 to a constant weight at 80°C, and soak the dried cotton-wool blended fabric in a polyacrylate emulsion with a concentration of 4o.w.f% at a bath ratio of 1:20; and Add acetic acid to the polyacrylate emulsion to adjust the pH value to 6.0; then add JFC penetrant with a concentration of 4g / L and stir, smooth and soften the cotton-wool blended fabric at 35°C for 1h, and finally dry it at 85°C for 5min, and then Dried to constant weight at 105°C to obtain a smooth and soft cotton-wool blended fabric.

Embodiment 2

[0032] The present embodiment provides a cotton-wool blended fabric and its smooth and soft process, which comprises the following steps:

[0033] S1. Put the cotton-wool blended fabric in an environment with a temperature of 65°C and an ultrasonic power of 200W for 0.5h;

[0034] S2. Dry the cotton-wool blended fabric after ultrasonication in step S1 to a constant weight at 100°C, and immerse the dried cotton-wool blended fabric in a polyacrylate emulsion with a concentration of 7o.w.f% at a bath ratio of 1:30; and Add acetic acid to the polyacrylate emulsion to adjust the pH value to 4.0; then add JFC penetrant with a concentration of 5g / L and stir, smooth and soften the cotton-wool blended fabric at 45°C for 0.75h, and finally dry at 95°C for 5min. Then dry to constant weight at 106° C. to obtain a smooth and soft cotton-wool blended fabric.

Embodiment 3

[0036] The present embodiment provides a cotton-wool blended fabric and its smooth and soft process, which comprises the following steps:

[0037] S1. Put the cotton-wool blended fabric in an environment with a temperature of 58°C and an ultrasonic power of 225W for 0.5h;

[0038] S2. Dry the cotton-wool blended fabric after ultrasonication in step S1 to a constant weight at 90°C, and soak the dried cotton-wool blended fabric in a polyacrylate emulsion with a concentration of 5.5o.w.f% at a bath ratio of 1:25; and Add acetic acid to the polyacrylate emulsion to adjust the pH value to 5.0; then add JFC penetrant with a concentration of 6g / L and stir, smooth and soften the cotton-wool blended fabric at 40°C for 0.85h, and finally dry at 90°C for 5min, and then Dry to constant weight at 104°C to obtain a smooth and soft cotton-wool blended fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com