Hole body construction method of reinforced concrete porous circular pipe culvert

A reinforced concrete and construction method technology, applied in the direction of buildings and road floors, etc., can solve the problems of large labor occupation, long construction time, and influence on construction efficiency, so as to improve external and internal quality, improve construction efficiency, and shorten construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

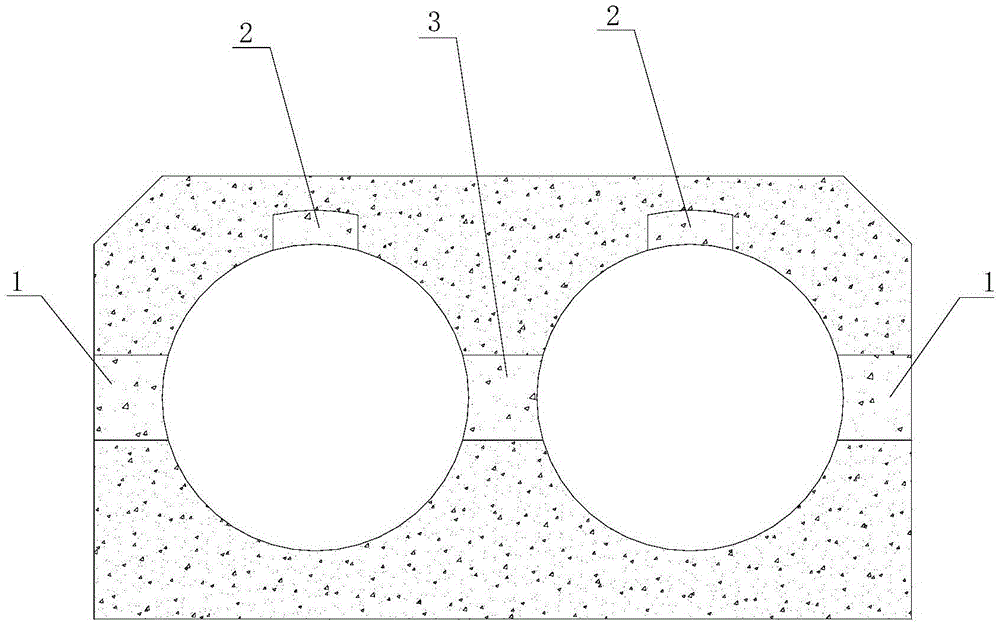

[0032] see figure 1 A method for constructing a hole body of a reinforced concrete perforated circular pipe culvert, comprising the following steps:

[0033] S1 Prefabricated side concrete pad 1, top concrete pad 2 and middle concrete pad 3. Among them, arc-shaped positioning surfaces are arranged on one side of the side concrete pad, the lower end surface of the top concrete pad, and both sides of the middle concrete pad. The arc-shaped positioning surfaces on the three types of pads are: Isometric arc surface.

[0034] S2 Excavating the foundation trench.

[0035] Concrete cushion is poured in the foundation groove of S3, and the thickness of the concrete cushion is generally 5cm.

[0036] S4 Bind multiple reinforcement cages on the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com