Detachable large-span pre-stressed integral tension awning and construction method thereof

An overall tensioning and prestressing technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of no possibility of disassembly and reconstruction in different places, the inability to realize super large spans, and inconvenience of disassembly, etc., and achieve light weight , Reduce the basic cost and facilitate disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

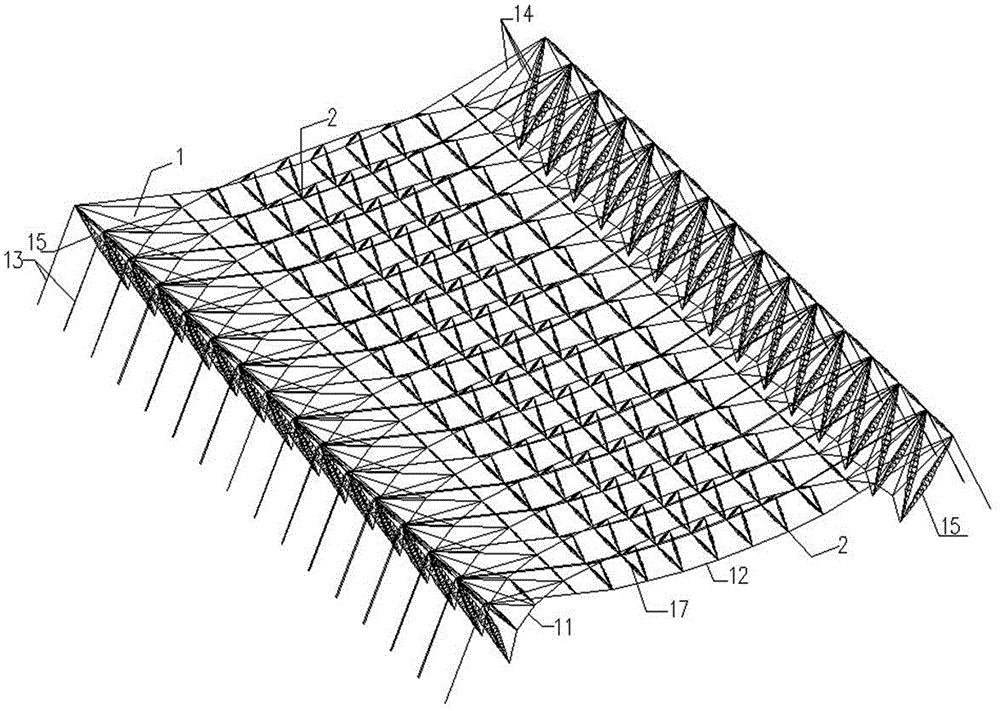

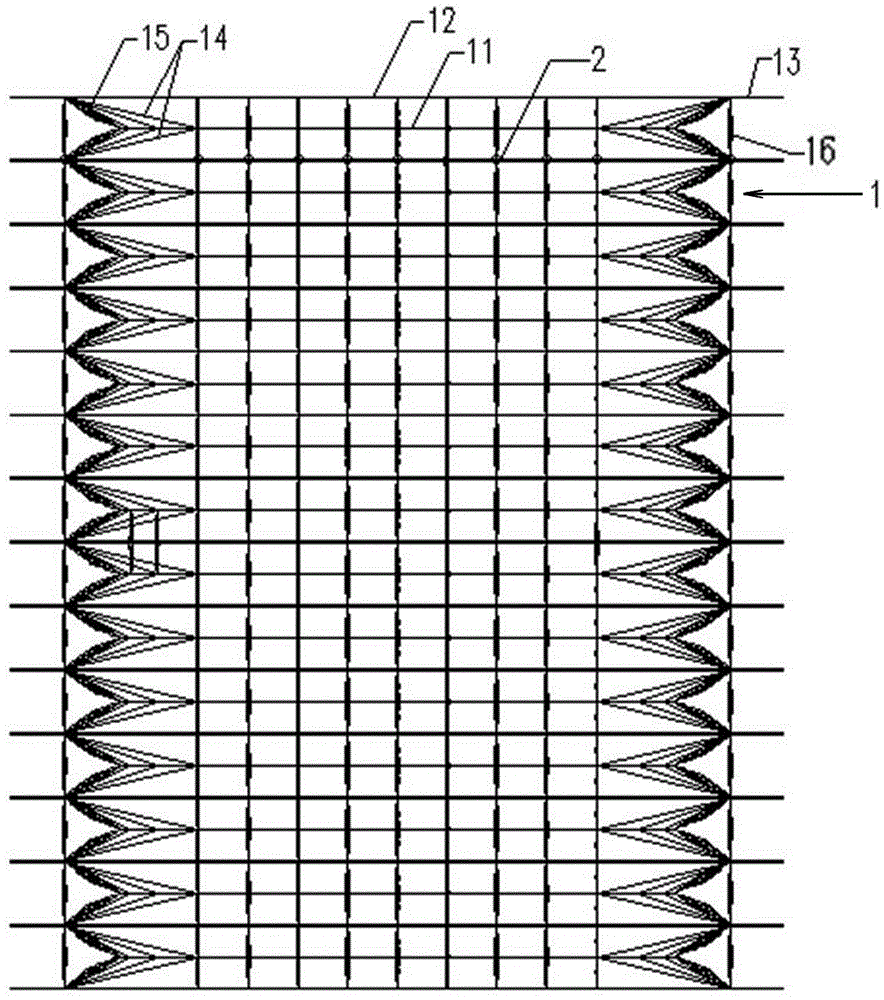

[0049] Examples see figure 1 As shown, this detachable large-span prestressed overall tensioned canopy includes two or more integral tensioned cable truss units 1 arranged in parallel, and pin-type connectors between two adjacent integral tensioned cable truss units 1 2, and the membrane laid between the valley cables 12 and the ridge cables 11 of the integral tension cable truss unit.

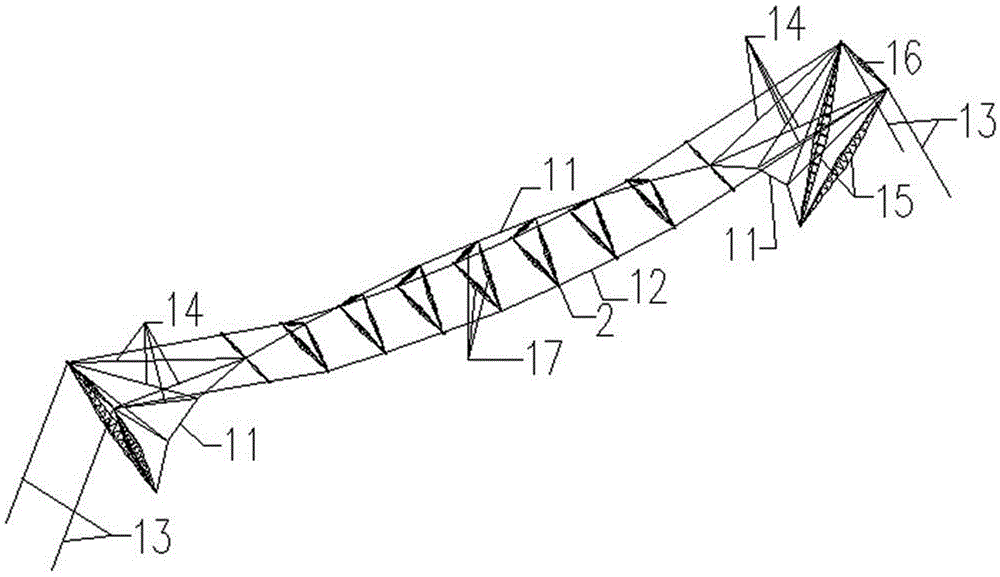

[0050] see Figure 1-5As shown, the integral tension cable truss unit 1 is composed of a group of ridge cables 11, two groups of valley cables 12, a support truss 17, an end outer cable 13, an inner cable 14, an end inclined column 15, and a horizontal column on an inclined column. The triangular space formed between the group of ridge cables 11 and the two groups of valley cables 12 is connected by a support truss 17, and the support truss 17 is a space shuttle-shaped truss or a triangular truss connected by a single rod. The two ends of the overall tension cable truss unit 1 have two end s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com