Special-shaped freezer used in tunnel steel tube curtain

A technology of freezer and steel pipe, which is applied in the field of special-shaped freezer inside the tunnel steel pipe curtain, which can solve the problems of limited freezing effect and inability to form auxiliary freezing of the freezing main pipe, so as to increase heat exchange efficiency, realize water sealing and reinforcement, increase The effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

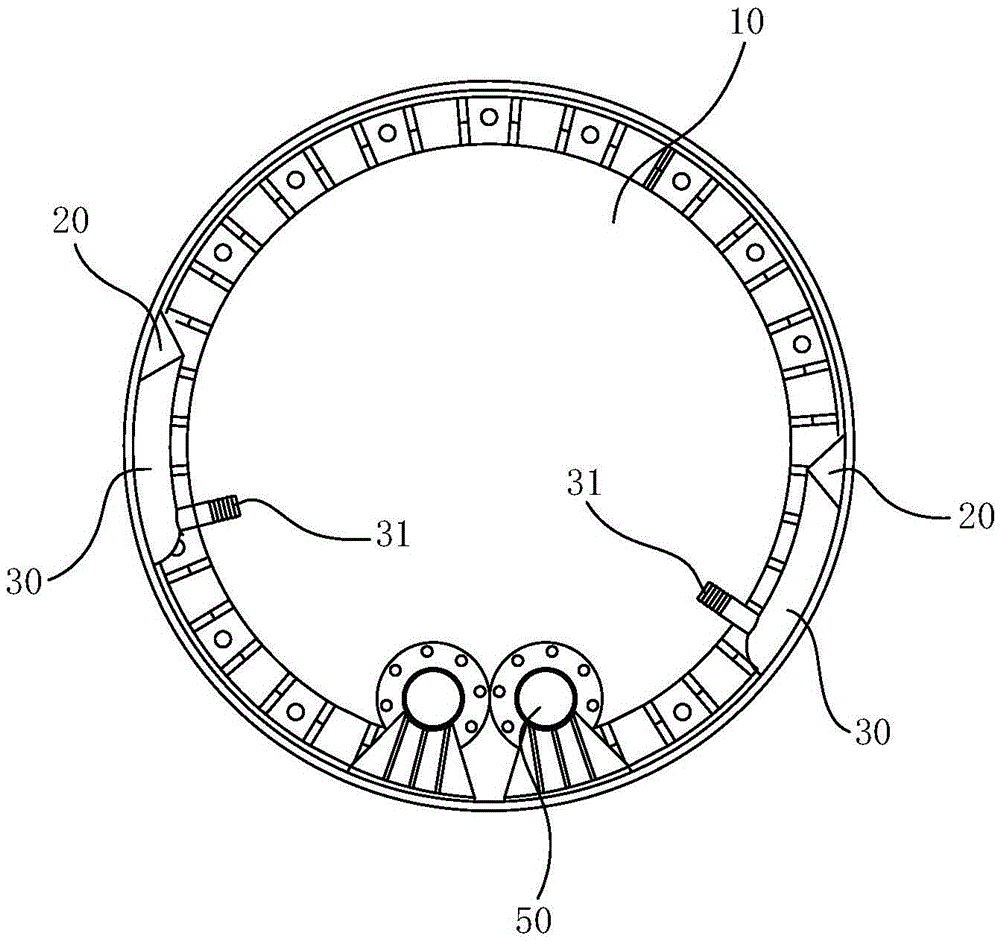

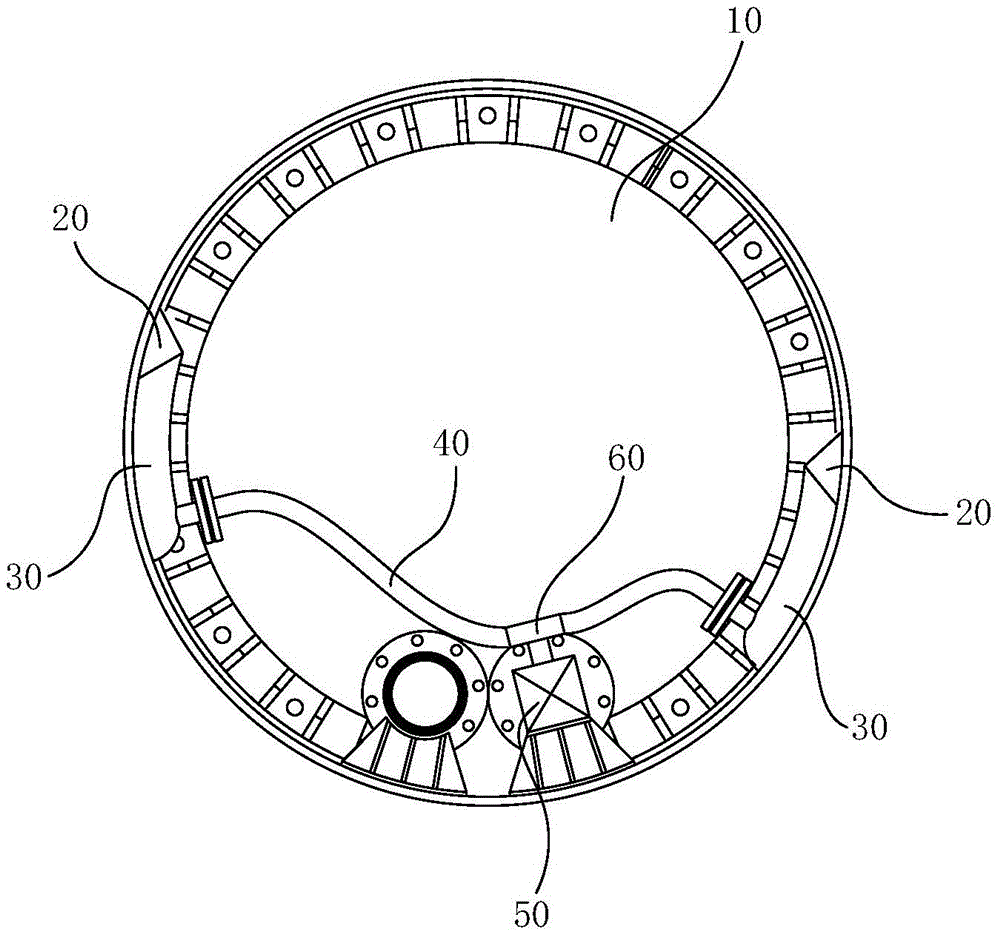

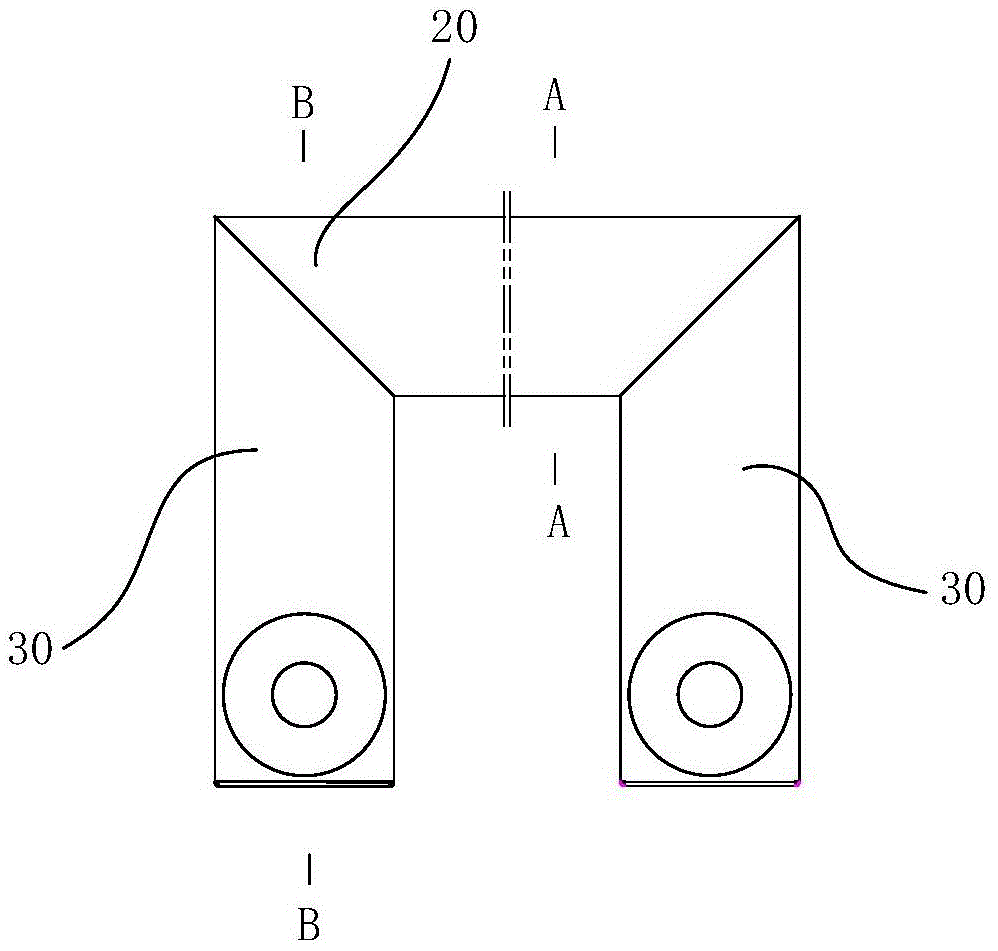

[0011] combine Figure 1 to Figure 5 , to further illustrate the present invention

[0012] A special-shaped freezer in a tunnel steel pipe curtain, including a special-shaped pipe 20 arranged against the inner wall of the jacking pipe 10. The cross-sectional shape of the special-shaped pipe 20 is a triangular structure as a whole. The two ends of the special-shaped pipe 20 are respectively provided with a refrigerant inlet and a refrigerant outlet to communicate with the refrigerant outlet and the refrigerant inlet of the refrigeration device respectively.

[0013] Use the refrigeration device to guide the refrigerant into the special-shaped tube 20, and make the cross-section of the special-shaped tube 20 into a triangular structure. The triangle here is not necessarily a standard triangle, but an approximate triangular shape. The inner wall contact surface of the pipe 20 is the largest, which can maximize the contact area with the inner wall of the jacking pipe 20, thereby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com