Novel gear pump with non-full-tooth gears

A non-full-tooth, gear pump technology, applied in the direction of rotary piston pumps, rotary piston/swing piston pump components, pumps, etc., can solve the problem of many wearing parts, high cost, low suction negative pressure and low discharge pressure and other problems, to achieve the effect of low meshing frequency, good self-priming, and large compression ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

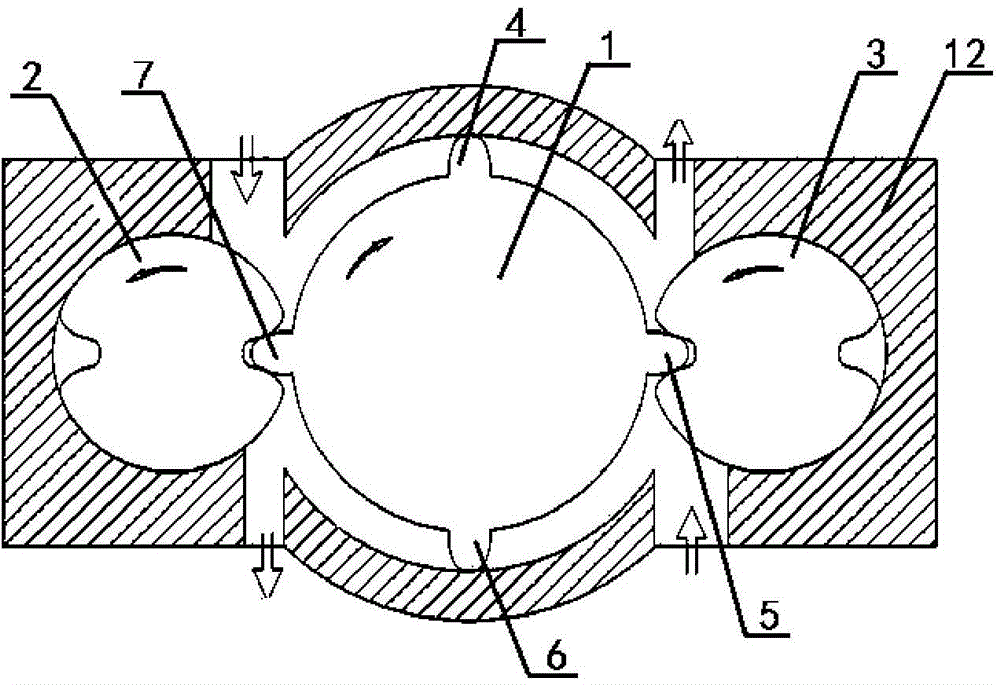

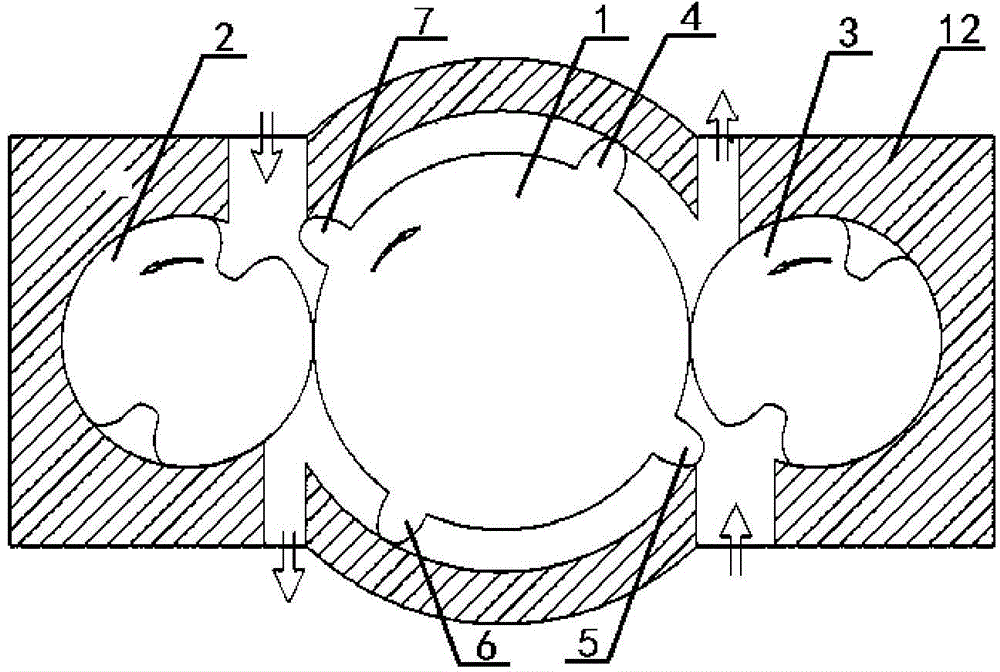

[0034] Such as Figure 1-3 As shown, the non-full-toothed new gear pump described in the embodiment of the present invention includes the pump body 12 and the main wheel 1, the driven wheel I2, and the driven wheel II3 in the inner cavity of the pump body 12, and the main wheel 1 is installed inside the pump body 12. , the driven wheel I2 and the driven wheel II3 are non-full-toothed gears, and the driven wheels can be set to an even number. The driven wheel I2 and the driven wheel II3 are respectively arranged on the left and right sides of the main wheel 1. The center of the wheel 1 is a symmetrical point in contact with each other for sealing. A compression cavity is formed inside the pump body 12 and the compression cavity is symmetrically distributed; an even number of teeth are set on the outer edge of the main wheel 1, which can be set to four, respectively, teeth I4, teeth II5, Teeth Ⅲ6 and tooth Ⅳ7. At the same time, two tooth slots are respectively set on the outer e...

Embodiment 2

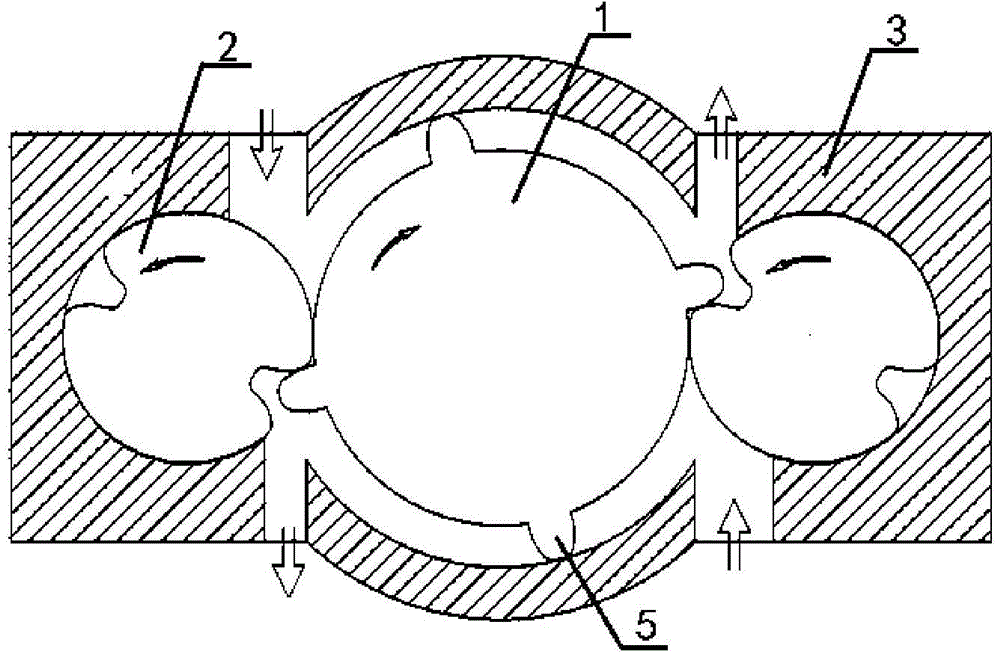

[0036] Such as Figure 4-5 As shown, the embodiment of the present invention can be improved to be used as a vacuum pump. The main wheel 1, the driven wheel I2 and the driven wheel II3 are installed inside the pump body 12, all of which are non-full-toothed gears, and the driven wheels can be set to an even number. , the driven wheel I2 and the driven wheel II3 are arranged on the left and right sides of the main wheel 1 respectively; the air inlet I8 and the air inlet II11 are respectively set outside the pump body 12 and the two air inlets are respectively arranged on the pump body 12 On both sides, compression chambers are formed inside the pump body 12 and the compression chambers are symmetrically distributed; an even number of teeth are set on the outer edge of the main wheel 1, which can be set as four teeth I4, teeth II5, teeth III6, and teeth IV7. There are two tooth slots on the outer edge of each driven wheel. The driven wheel I2 or driven wheel II3 has a small surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com