Electromagnetic valve with multiple stages of diaphragms

A solenoid valve and diaphragm technology, applied in the field of solenoid valves, can solve the problems of large-area wiring, difficult power supply, poor safety, valve core coil volume, power, and large voltage, etc., to achieve convenient layout, reasonable structural design, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

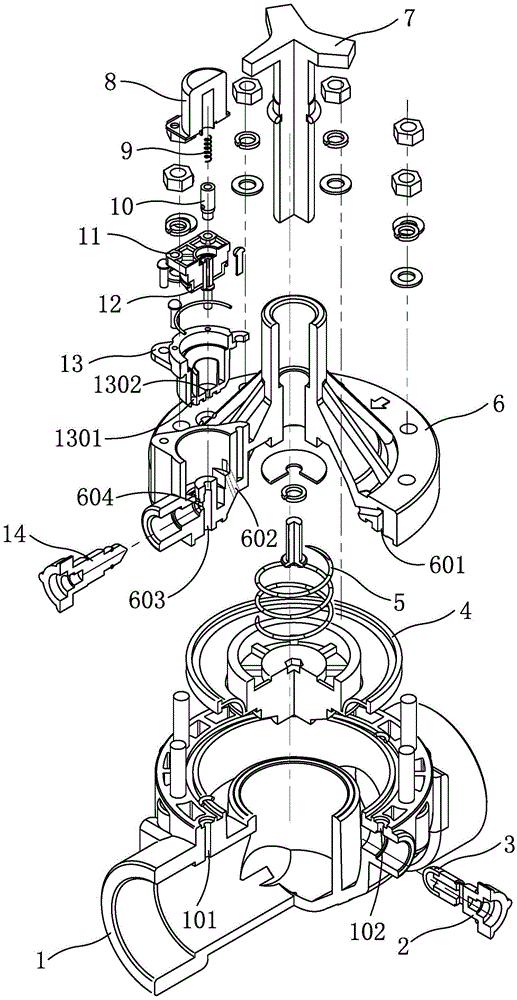

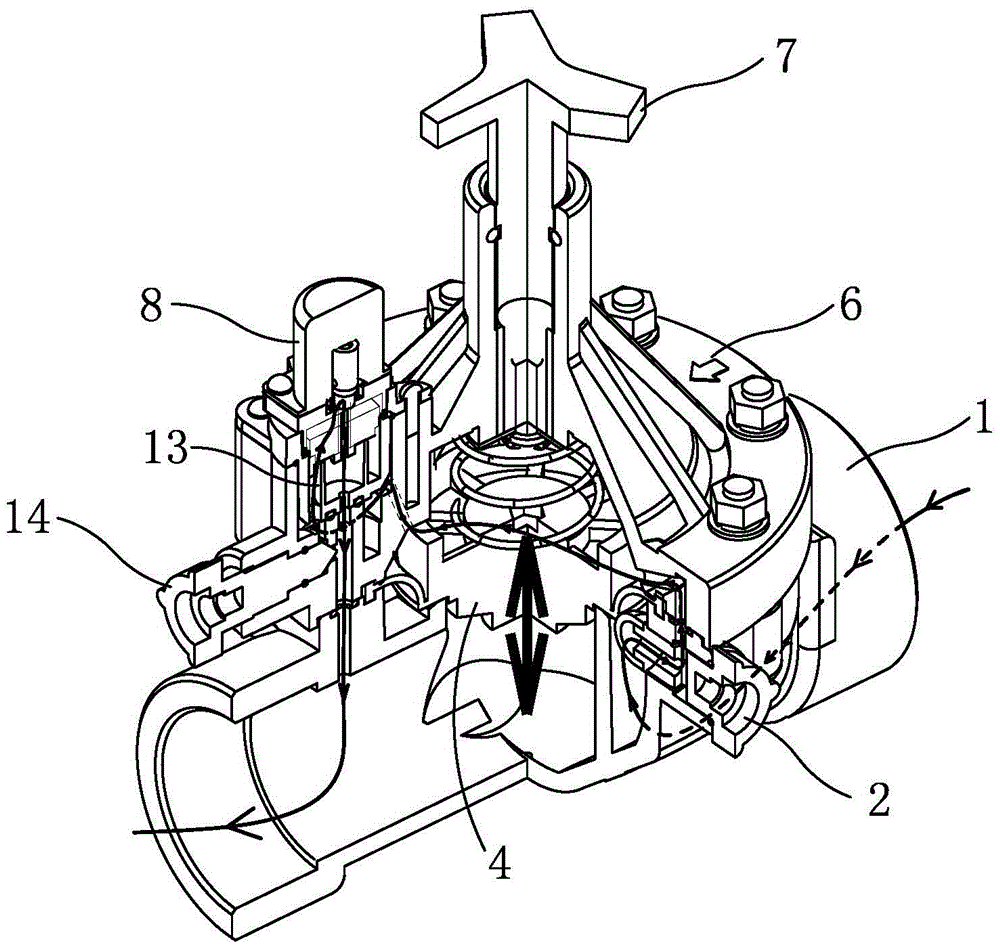

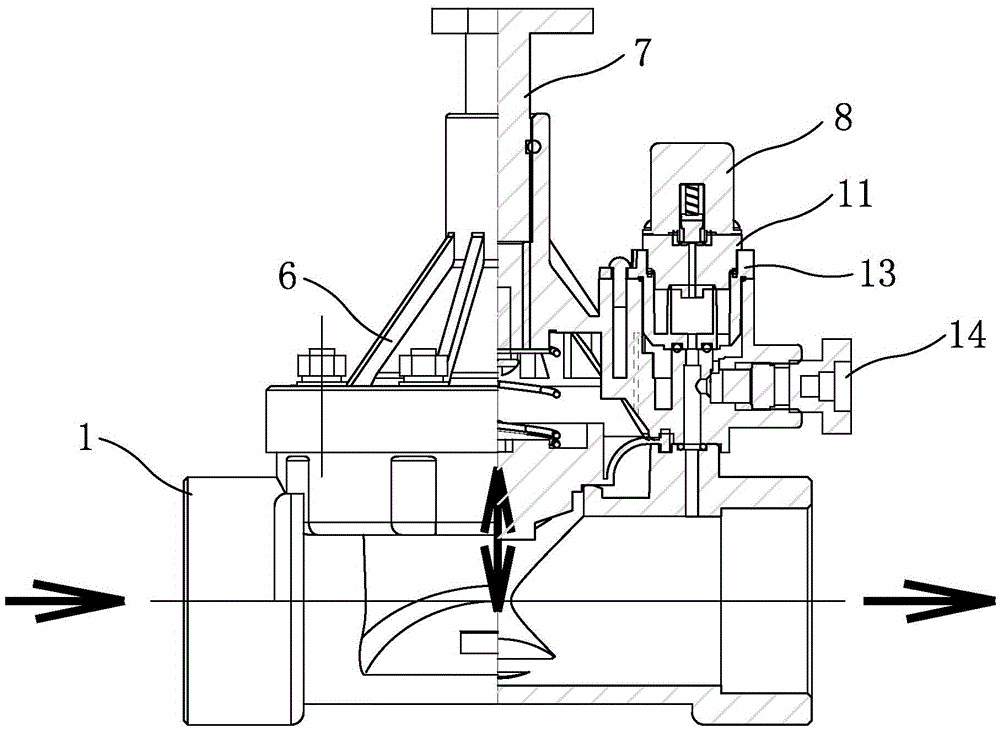

[0025] Now in conjunction with the accompanying drawings, the structure and use of the present invention will be further described. Such as Figure 1 to Figure 8As shown, the solenoid valve uses a voltage of 3-6V, including the lower valve body 1, the first-stage diaphragm 4, the upper valve cover 6, the manual adjustment rod 7, the second-stage pilot seat 13 and the miniature solenoid valve. Its specific structure is as follows: 1. The first-stage diaphragm clamps the chamber between the lower valve body and the upper valve cover, and divides the chamber into an upper chamber and a lower chamber. The above-mentioned chamber is the first-stage chamber, and the upper chamber of the first-stage diaphragm A first-level diaphragm spring 5 is arranged in the chamber, and the two ends of the first-level diaphragm spring respectively resist the first-level diaphragm and the upper valve cover, and one end of the lower chamber is a water inlet, and the other end is a water outlet. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com