Tamping bar for deep hole blasting charge

A technology of deep hole blasting and charging, which is applied in blasting and other directions, can solve the problems of gun stick falling off and charging failure, and achieves the effect of convenient drilling and avoiding charging failure or safety accident.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

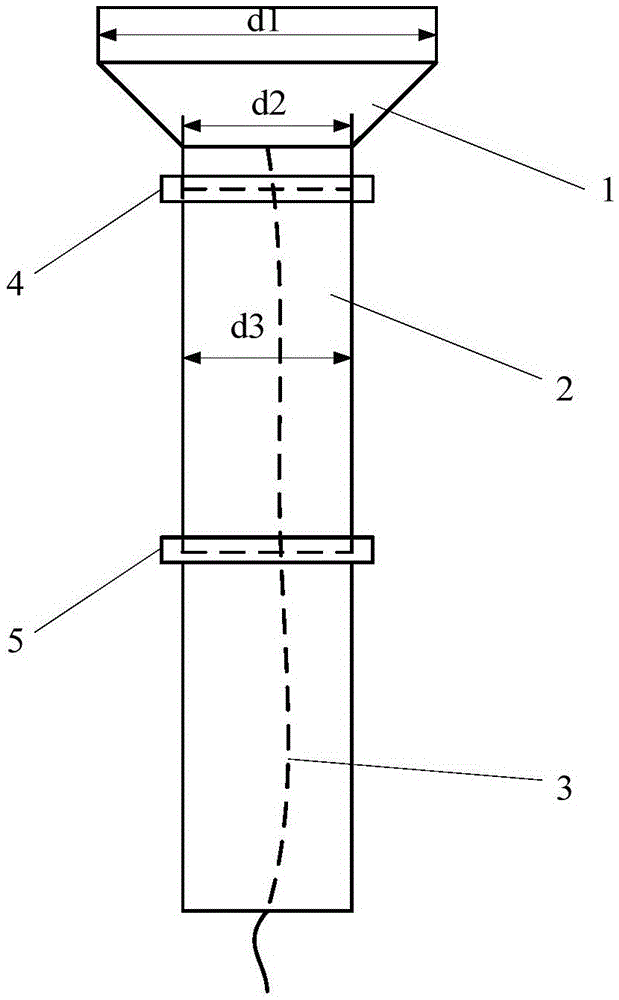

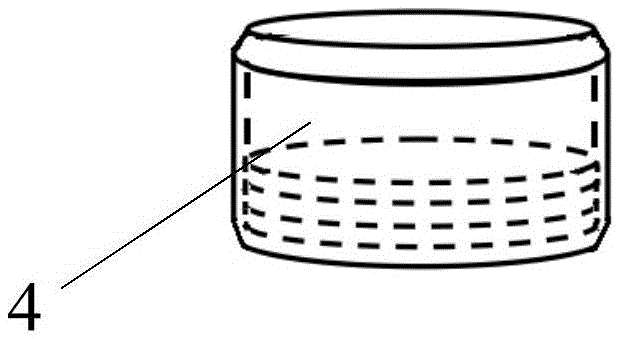

[0047] The depth of the blasthole is 95m, the diameter of the blasthole is 102mm, and the diameter of the explosive grain is 75mm. The diameter d1 of the front end of the variable-diameter nozzle is selected as 75mm, the diameter d2 of the rear end is 38mm, the diameter of the pipe body is 38mm, and the length of a single pipe body is 2000mm. Choose No. 8 iron wire to connect the variable-diameter gun head and each tube body. If you connect 55 single tubes with a length of 2000mm, you can form a deep-hole gun stick with a length of about 110 meters.

Embodiment 2

[0049] The depth of the blasthole is 30m, the diameter of the blasthole is 89mm, and the diameter of the explosive grain is 60mm. The diameter d1 of the front end of the variable-diameter gun head is selected as 60mm, and the diameter d2 of the rear end is 32mm. The diameter of a single tube is 32mm, and the length of the tube is 1800mm. Choose nylon rope to connect the variable diameter gun head and each pipe body. If you connect 20 single pipes with a length of 1800mm, you can form a deep hole gun stick with a length of about 36 meters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com