Liquid level detector with pressure stabilization device and method of liquid level detector

A technology of liquid level detectors and pressure stabilizing devices, which is applied in the direction of displaying liquid level indicators, measuring devices, and liquid level indicators through pressure measurement, which can solve the problems of insufficient space convenience, difficult reading, and equipment overhaul, etc. Intuitive and reliable measurement results, wide application range and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

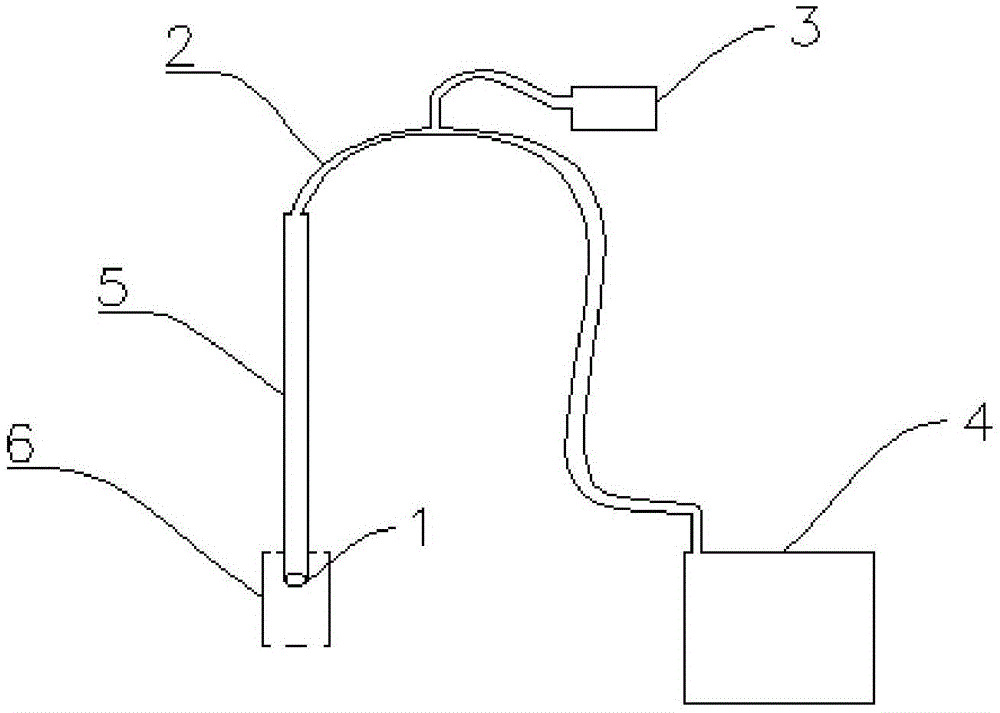

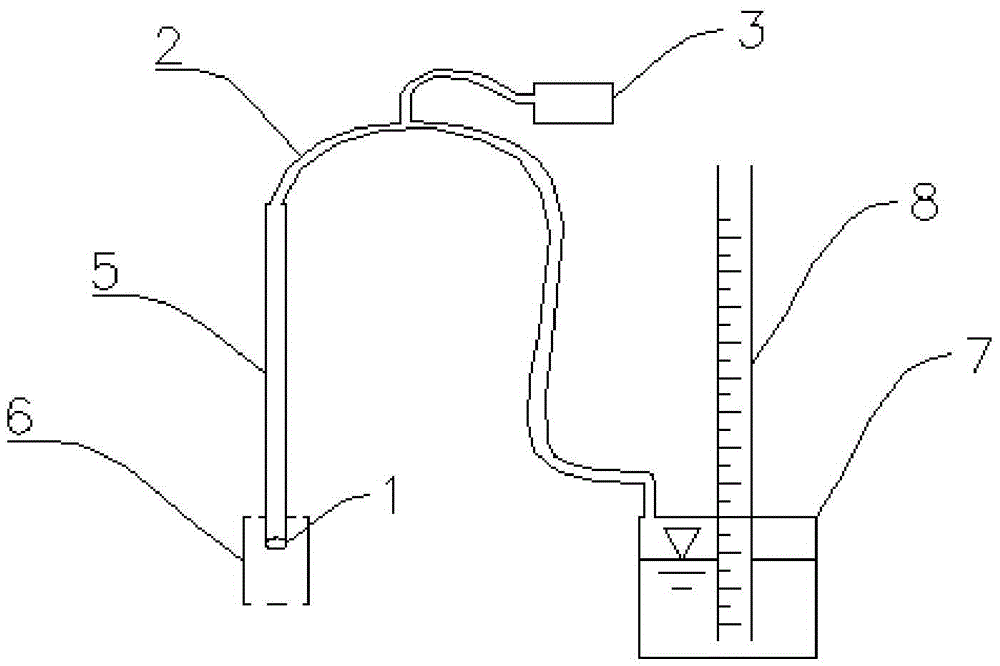

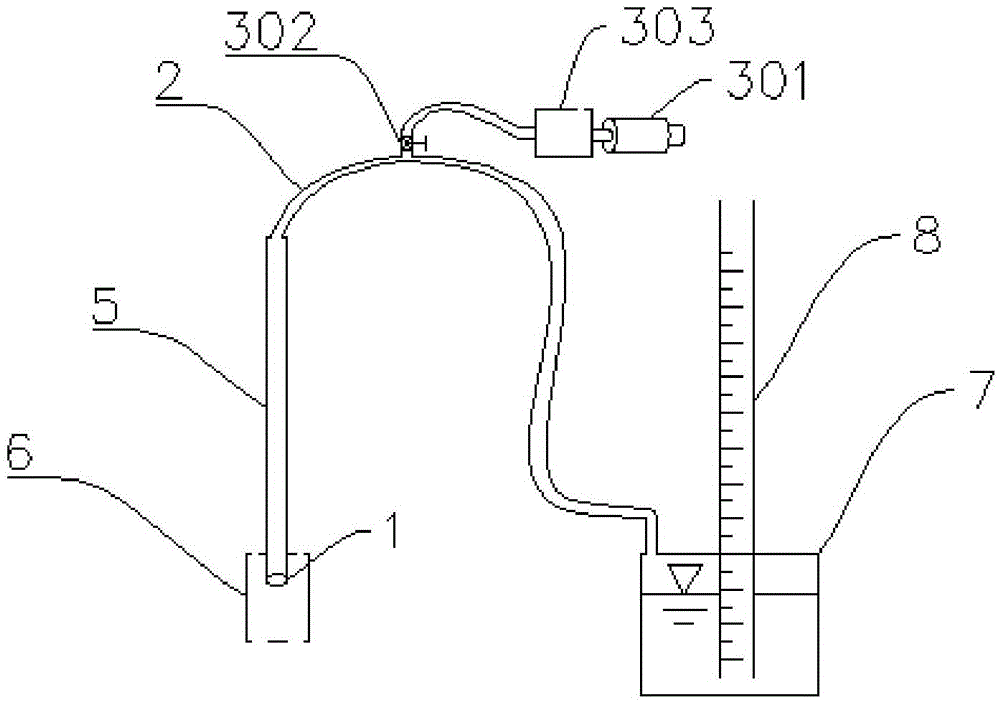

[0020] like figure 1 As shown, a liquid level detector with a pressure stabilizing device includes a measuring port 1, a connecting pipe 2, an exhaust device 3, a pressure measuring device 4, a liquid level detection rod 5 and a pressure stabilizing barrel 6; the liquid level detection rod 5 is hollow, and the measurement port 1 is opened at one end of the liquid level detection rod 5, and the other end of the liquid level detection rod 5 is airtightly connected with the pressure measuring device 4 through the connecting pipe 2, and the pressure measuring device 4 is used to measure the air pressure in the connecting pipe 2; The device 3 is connected with the connecting pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com