Multifunctional shearing test fixture used for composite material parameter identification

A technology of parameter identification and shear test, applied in the direction of applying stable shear force to test the strength of materials, analyzing materials, measuring devices, etc., can solve the problems of high requirements for guide rail installation and processing, inconvenient, single function, etc., to achieve Compact structure, easy to disassemble and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

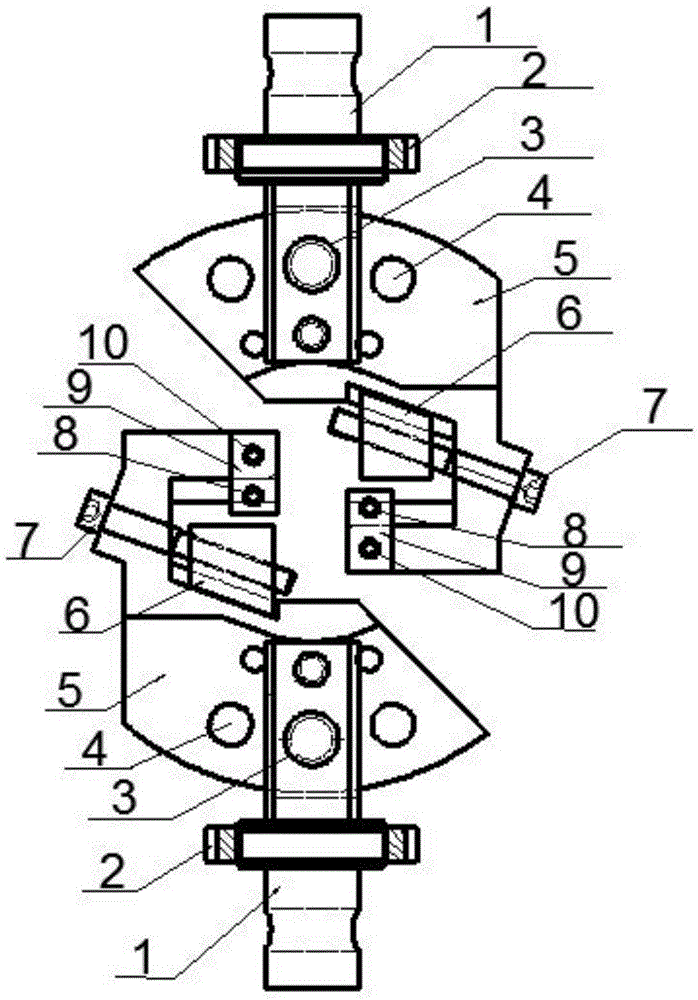

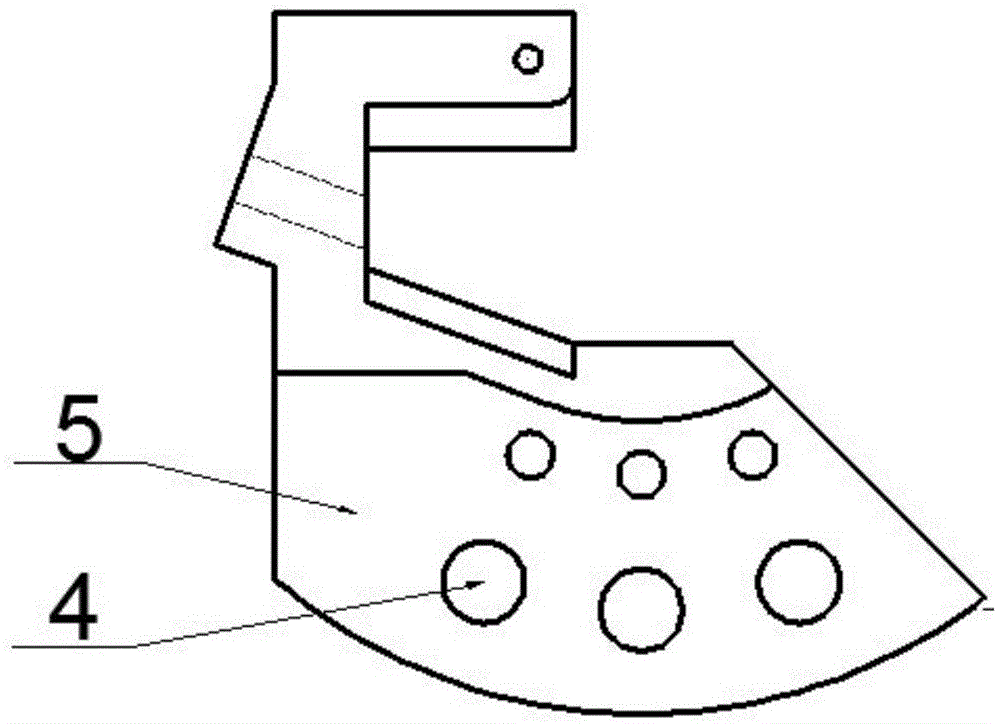

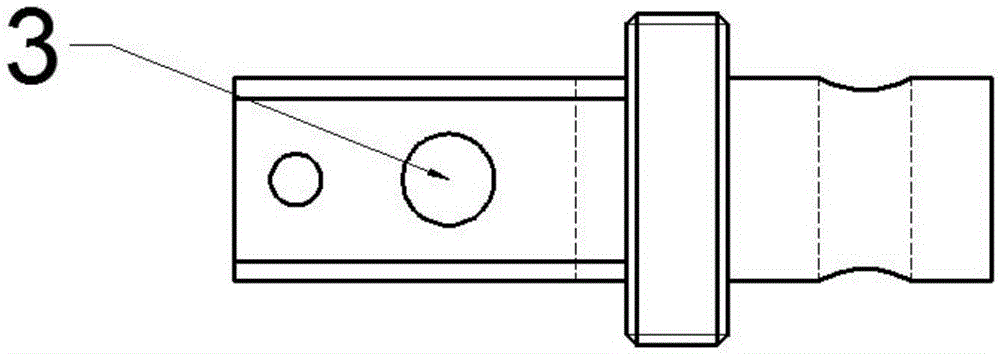

[0036] A multi-functional shear test fixture for composite material parameter identification, which is composed of upper and lower parts, the upper fixture is connected to the loading part of the testing machine through locking pins, and the lower part is connected to the platform of the testing machine through locking pins; The above-mentioned upper clamping body and the lower specific structure are the same and have a centrally symmetrical structure; the locking ring 2 is assembled to the connecting piece 1 through threads, the connecting shaft of the connecting piece 1 is connected with the testing machine through a pin hole, and the locking ring 2 to achieve the purpose of tight connector 1. Use a pin to connect it with the connector 1 through a set of through holes in the middle of the clamping part 5, clamp the pressing part 6 on the guide rail of the clamping part 5, and connect the pressing part 6 and the clamping part 5 through the adjusting bolt 7 connect them. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com