A welding seam pressure testing device and using method thereof

A pressure test and pressure technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of complex operation, expensive detection cost, long detection cycle, etc., and achieve high detection accuracy, easy operation and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

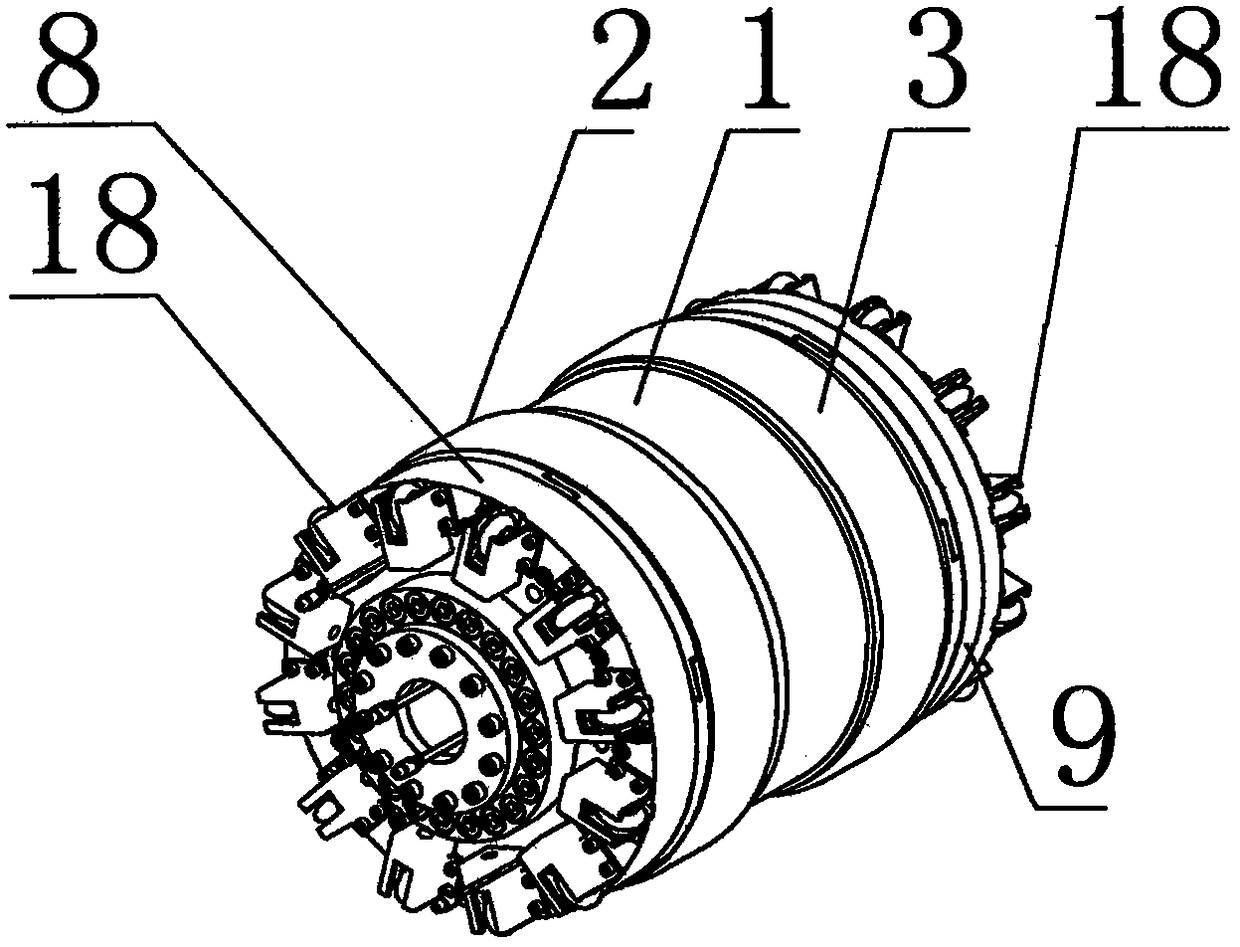

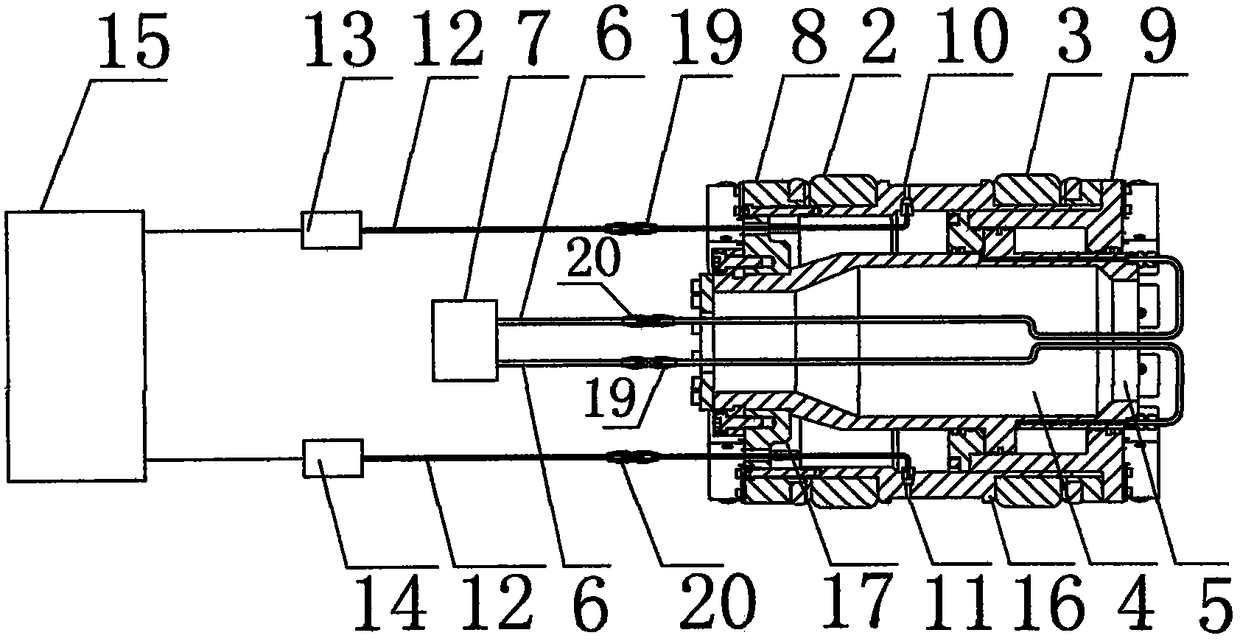

[0024] Attached below Figure 1-2 The structure and usage method of the welding seam pressure testing device of the present invention are described in detail.

[0025] A weld pressure test device, the weld pressure test device includes a main body 1, a hydraulic assembly arranged inside the main body, two rubber sealing rings 2, 3 sleeved on the main body and a Pressure test tube assembly; wherein: the two rubber sealing rings are arranged at intervals; the hydraulic assembly includes a cylinder 4, a piston rod 5 and hydraulic oil arranged in the cylinder; the cylinder is connected to the external hydraulic pressure through the first pipe 6 Pump 7; one end of the piston rod is set in the cylinder body, the other end protrudes out of the main body and can reciprocate in the cylinder body; the hydraulic component is fixedly installed through the compression flanges 8 and 9 arranged on both sides of the hydraulic component Inside the main body; the pressure test tube assembly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com