Enameled wire harness

A technology of enameled wire and wire core, applied in the direction of conductors, insulated cables, electrical components, etc., can solve the problems of mutual interference of enameled wires and poor signal stability, and achieve the effects of avoiding mutual interference, prolonging service life and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

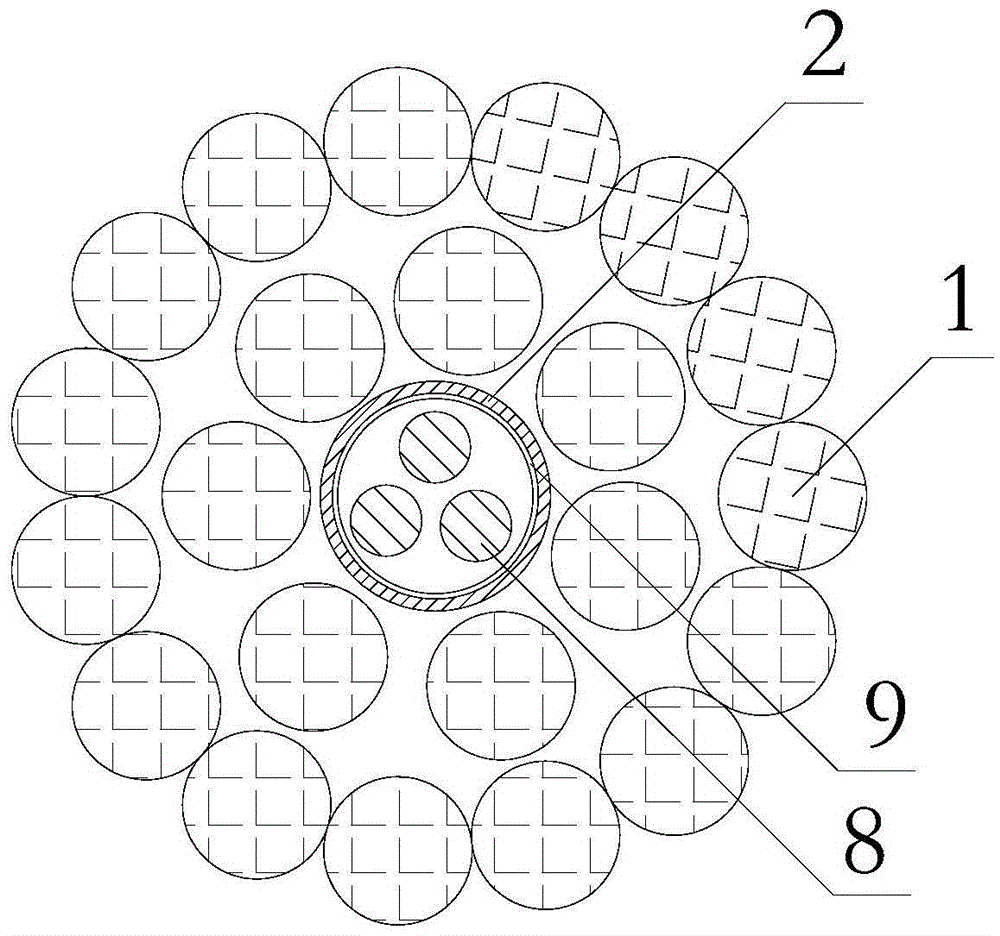

[0029] Such as figure 1 As shown, a schematic diagram of an enameled wire harness structure, including a multi-strand enameled wire 1 and a support tube 2 in a hollow structure, a plurality of strands of the enameled wire 1 and the support tube 2 are twisted to form a wire harness, and the support tube 2 is located in a multi-strand At the center position of the enameled wire 1 .

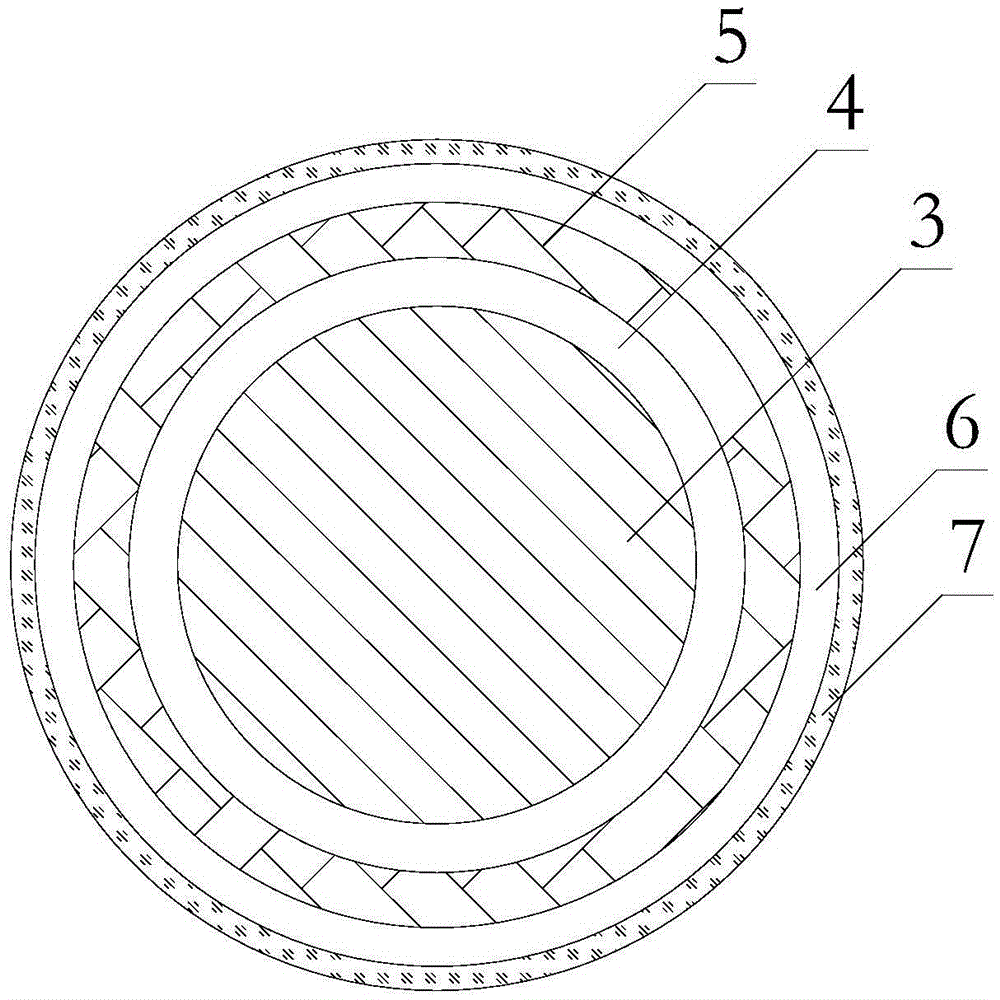

[0030] Such as figure 2 As shown, each strand of the enameled wire 1 includes a core 3, an intermediate layer 4, a first shielding layer 5 and a protective layer 6, and the intermediate layer 4, the first shielding layer 5 and the protective layer 6 are sequentially covered from the inside to the outside. on the surface of the wire cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com