Air inlet system and semiconductor processing device

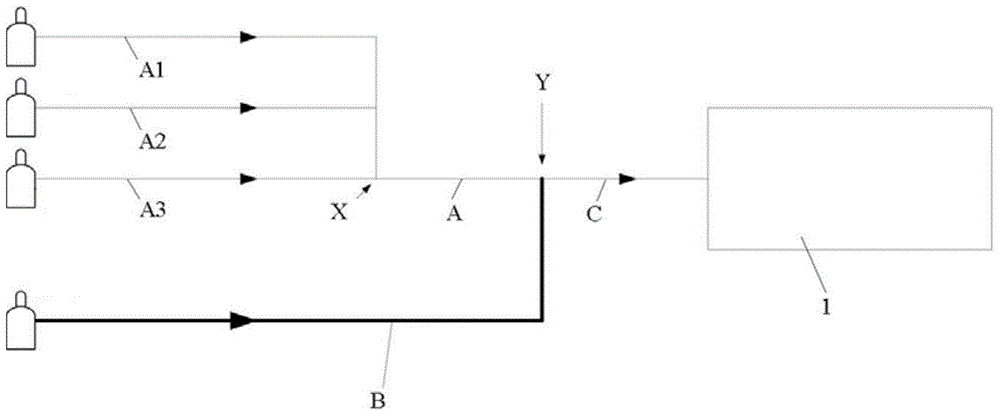

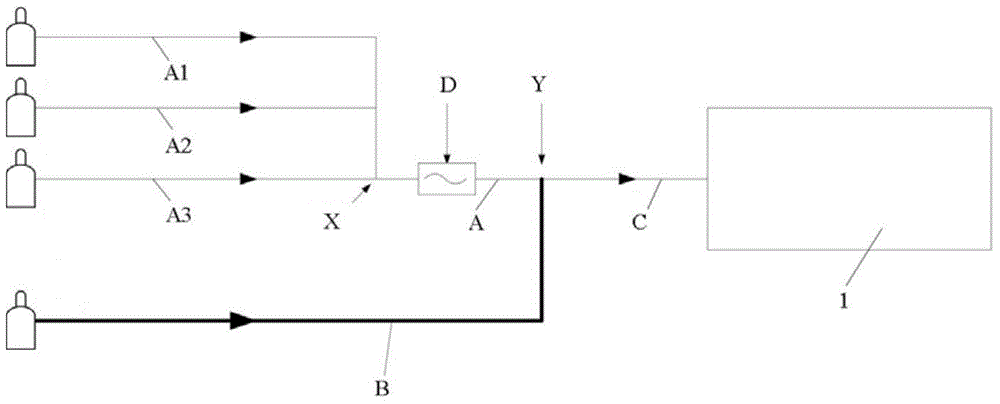

A gas intake system and gas technology, applied in the field of microelectronics, can solve the problems of affecting the uniformity of gas mixing, reducing the effect of gas pressure, stopping the flow, etc., to achieve favorable process results, reduce the risk of mutual collision, and improve the uniformity of mixing sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

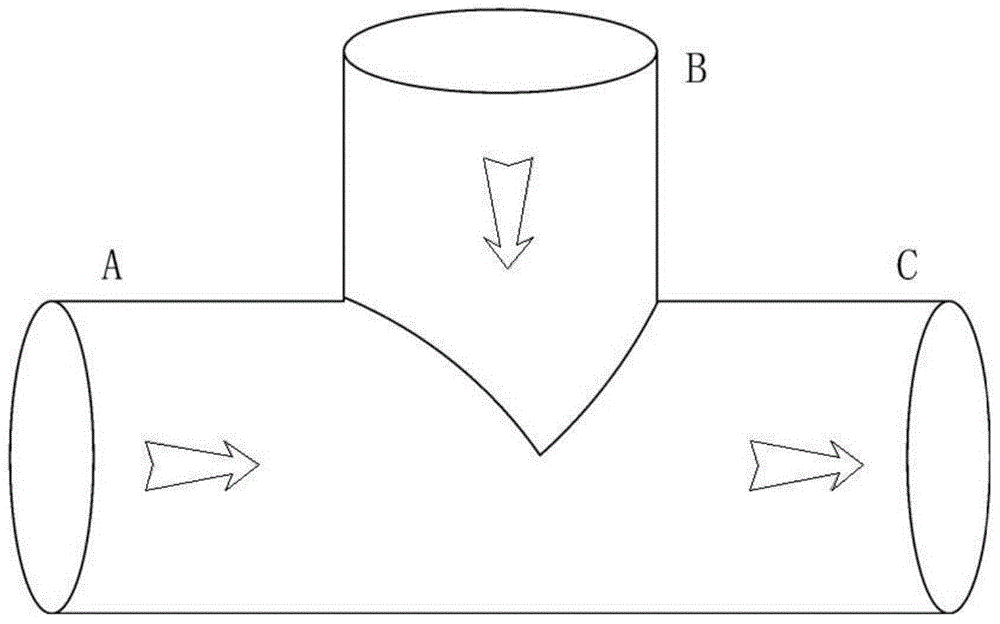

[0030] In order to enable those skilled in the art to better understand the technical solution of the present invention, the air intake system and semiconductor processing equipment provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0031] First of all, it needs to be explained that a type of gas that is gaseous at normal temperature is usually called unsaturated steam gas, such as N 2 , Cl 2 , O 2 , CF 4 , He, etc., this type of gas can usually be directly transported into the process chamber; a type of gas that is liquid at normal temperature or has a boiling point slightly lower than normal temperature is called saturated steam gas, such as SiCl 4 , BCl 3 etc. This type of gas is usually stored in a steel cylinder in the form of a liquid, and a saturated vapor is formed above the liquid. When gas intake is required, the saturated steam in the cylinder will be transported to the reaction chamber through a pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com