Energy gel and preparation method thereof

A technology of energy gels and mixtures, applied in the functions of food ingredients, food science, applications, etc., to achieve the effects of easy absorption, keeping thinking quick and active, and eliminating body fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

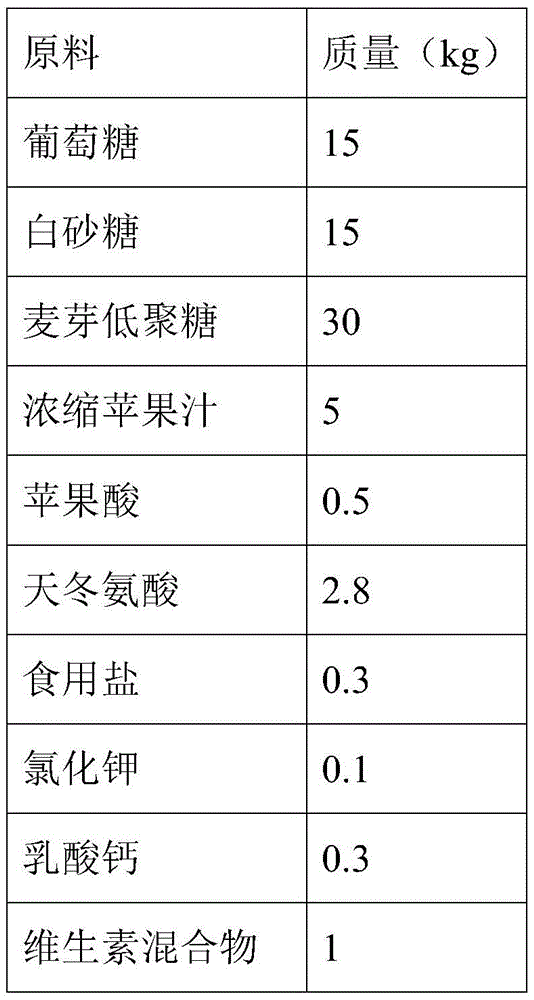

[0029] 1. The composition of raw materials is shown in the table below:

[0030]

[0031]

[0032] 2. Follow the steps below to prepare energy gels:

[0033] (1) Pour 18kg of pure water into the sugar pot for subsequent use;

[0034] (2) Add various sugar mixtures, edible salt, potassium chloride and calcium lactate in turn into the sugar pot, stir and heat up to 80-90°C;

[0035] (3) Add concentrated fruit juice into the sugar pot and keep it warm at 80-90°C;

[0036] (4) weighing malic acid, soybean oligopeptide, vitamin mixture and aspartic acid for subsequent use;

[0037] (5) Dissolve the mixture of step (4) in 2kg of purified water, and set aside;

[0038] (6) Pour the mixture into the flavoring tank from the sugar tank, and add malic acid, soybean oligopeptide, vitamin mixture and aspartic acid aqueous solution in turn under stirring;

[0039] (7) After stirring evenly, pour the mixed slurry into a storage tank for filling.

Embodiment 2

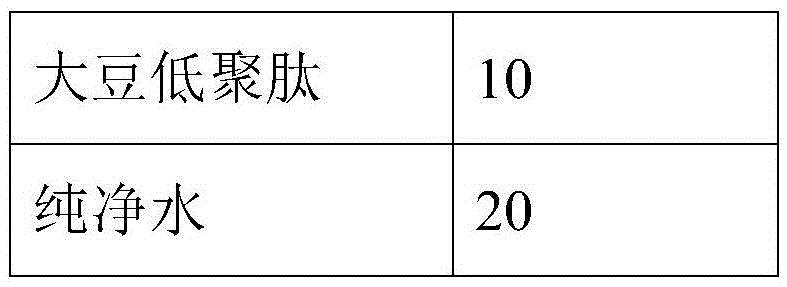

[0041] 1. The composition of raw materials is shown in the table below:

[0042]

[0043]

[0044] 2. Follow the steps below to prepare energy gels:

[0045] (1) Pour 20kg of pure water into the sugar pot for subsequent use;

[0046] (2) Add various sugar mixtures, edible salt, potassium chloride and calcium lactate in turn into the sugar pot, stir and heat up to 80-90°C;

[0047] (3) Add concentrated fruit juice into the sugar pot and keep it warm at 80-90°C;

[0048] (4) weighing malic acid, soybean oligopeptide, vitamin mixture and aspartic acid for subsequent use;

[0049] (5) Dissolve the mixture of step (4) in 5kg of purified water, and set aside;

[0050] (6) Pour the mixture into the flavoring tank from the sugar tank, and add malic acid, soybean oligopeptide, vitamin mixture and aspartic acid aqueous solution in turn under stirring;

[0051] (7) After stirring evenly, pour the mixed slurry into a storage tank for filling.

Embodiment 3

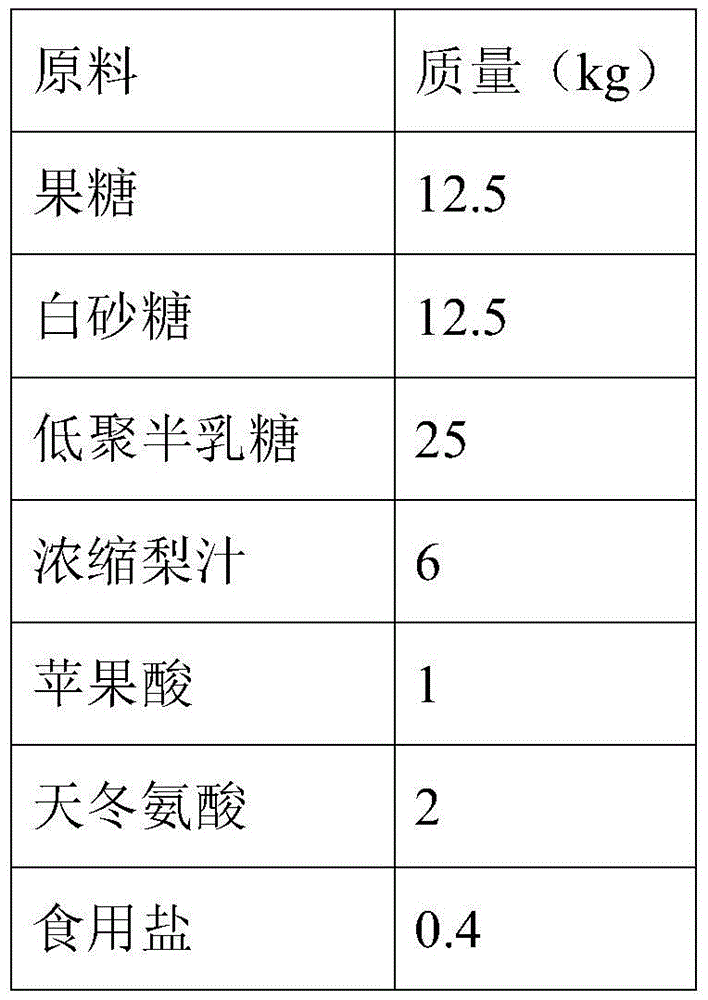

[0053] 1. The composition of raw materials is shown in the table below:

[0054]

[0055]

[0056] 2. Follow the steps below to prepare energy gels:

[0057] (1) Pour 10kg of pure water into the sugar pot for subsequent use;

[0058] (2) Add various sugar mixtures, edible salt, potassium chloride and calcium lactate in turn into the sugar pot, stir and heat up to 80-90°C;

[0059] (3) Add concentrated fruit juice into the sugar pot and keep it warm at 80-90°C;

[0060] (4) weighing malic acid, soybean oligopeptide, vitamin mixture and aspartic acid for subsequent use;

[0061] (5) Dissolve the mixture of step (4) in 3kg of purified water, and set aside;

[0062] (6) Pour the mixture into the flavoring tank from the sugar tank, and add malic acid, soybean oligopeptide, vitamin mixture and aspartic acid aqueous solution in turn under stirring;

[0063] (7) After stirring evenly, pour the mixed slurry into a storage tank for filling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com