Cut tobacco over-dried temperature and pressure increasing pipeline type conditioning system

A duct-type, dry-end technology, applied in the fields of tobacco preparation, application, and tobacco, can solve the problems of increasing the moisture regain cycle, uneven moisture regain between the cut tobacco and the surface cut tobacco, and large shredding of the dry end and dry end cut tobacco, so as to ensure complete The effect of reducing the moisturizing time and uniform moisturizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

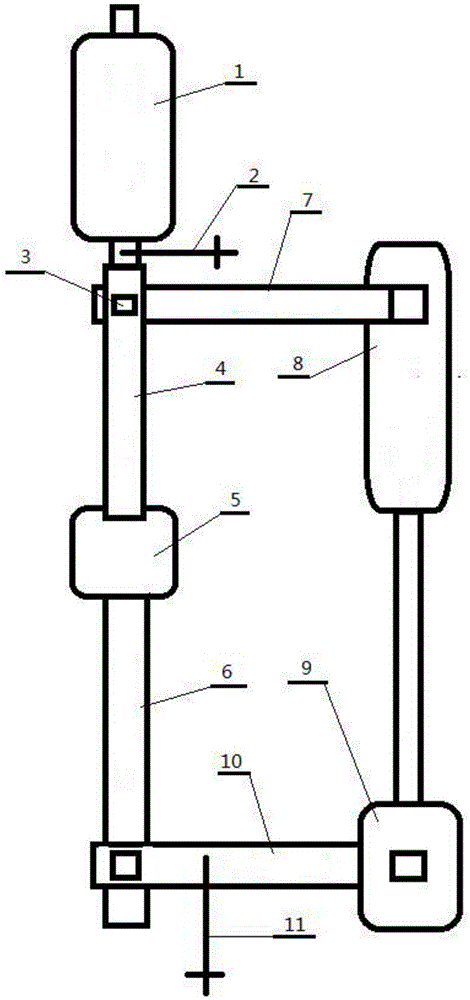

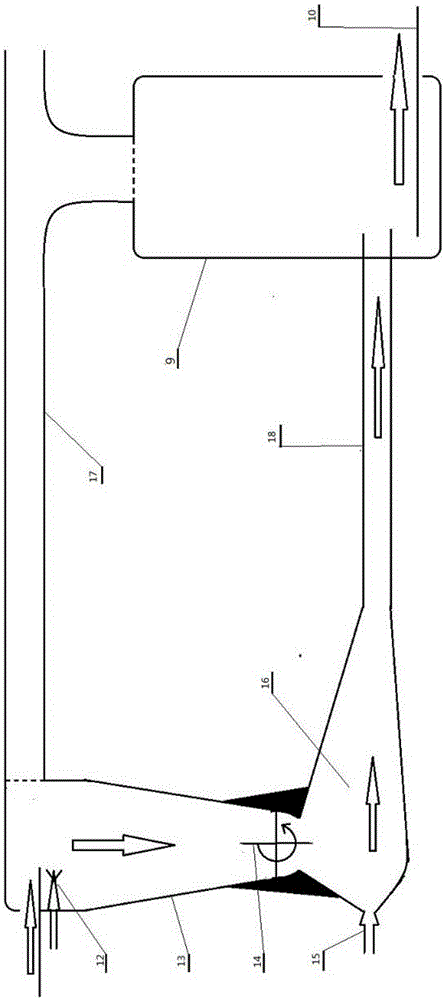

[0018] refer to figure 1 As shown in ‐2, a temperature-increased and pressurized pipeline-type moisture regain system for the dry head and tail of dried leaves, including a feed conveyor belt 7, a moisture regain device 8, an air-material separation bin 9, and a discharge conveyor belt 10. The moisture regain device 8 includes an atomizing nozzle 12 , an initial moisture return barrel 13 , an air lock 14 , a steam nozzle 15 , a moisture regain chamber 16 , an emptying pipe 17 , and a discharge pipe 18 . One end of the feed conveyor belt 7 is placed directly below the valve 3 of the discharge vibration tank, and the other end is connected to the feed port of the moisture regain device 8; the discharge port of the discharge pipeline 18 is connected with the gas material separation warehouse 9, and the gas material The separation bin 9 is connected with the conveyor belt 6 on the main production line through a discharge conveyor belt 10 .

[0019] The feed conveyor belt 7, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com