Full-automatic stone mill soybean milk machine

A soybean milk machine, fully automatic technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of not being able to enter the stone mill device, easy to adhere to its inner wall, and affect the quality of soybean milk, so as to ensure freshness and improve the quality of soybean milk. Shopping experience, the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

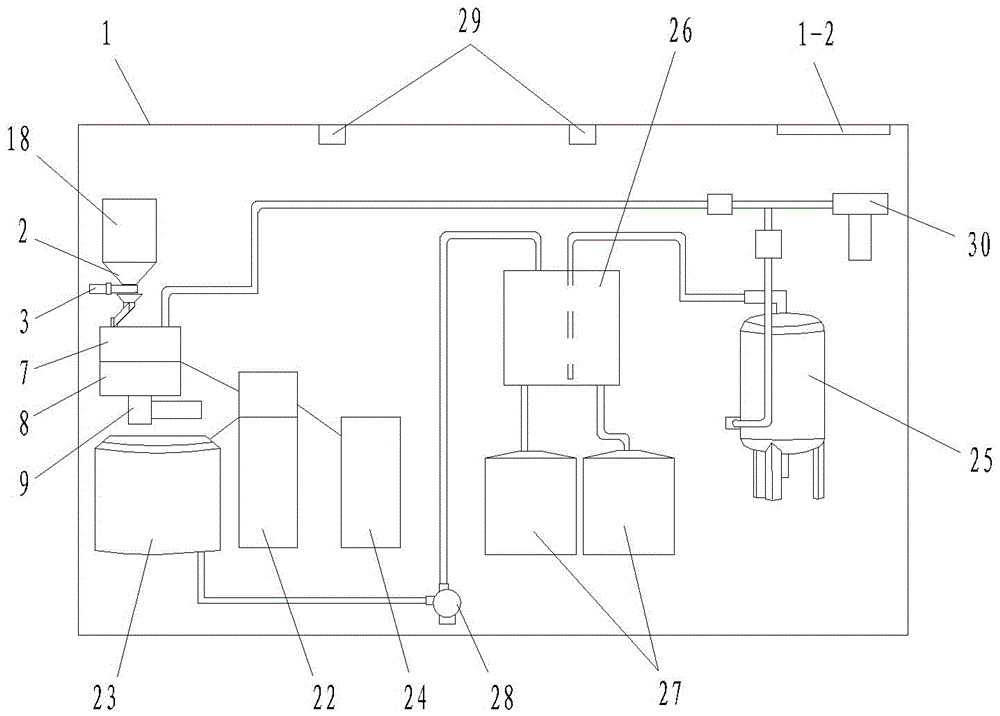

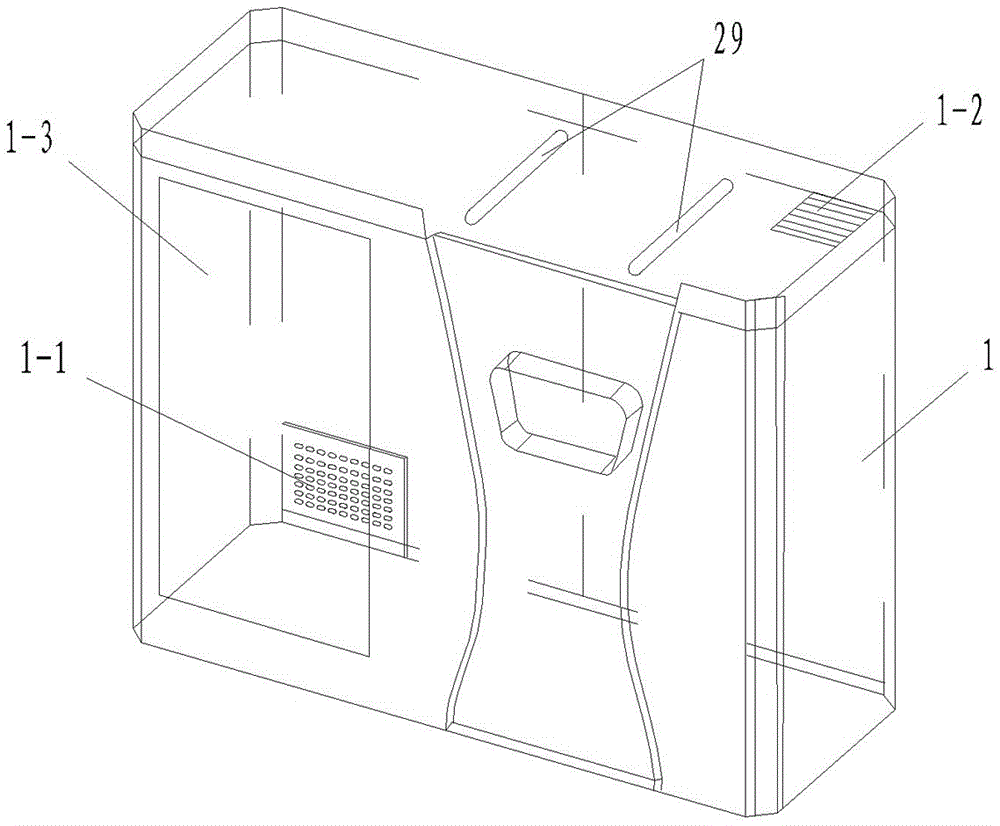

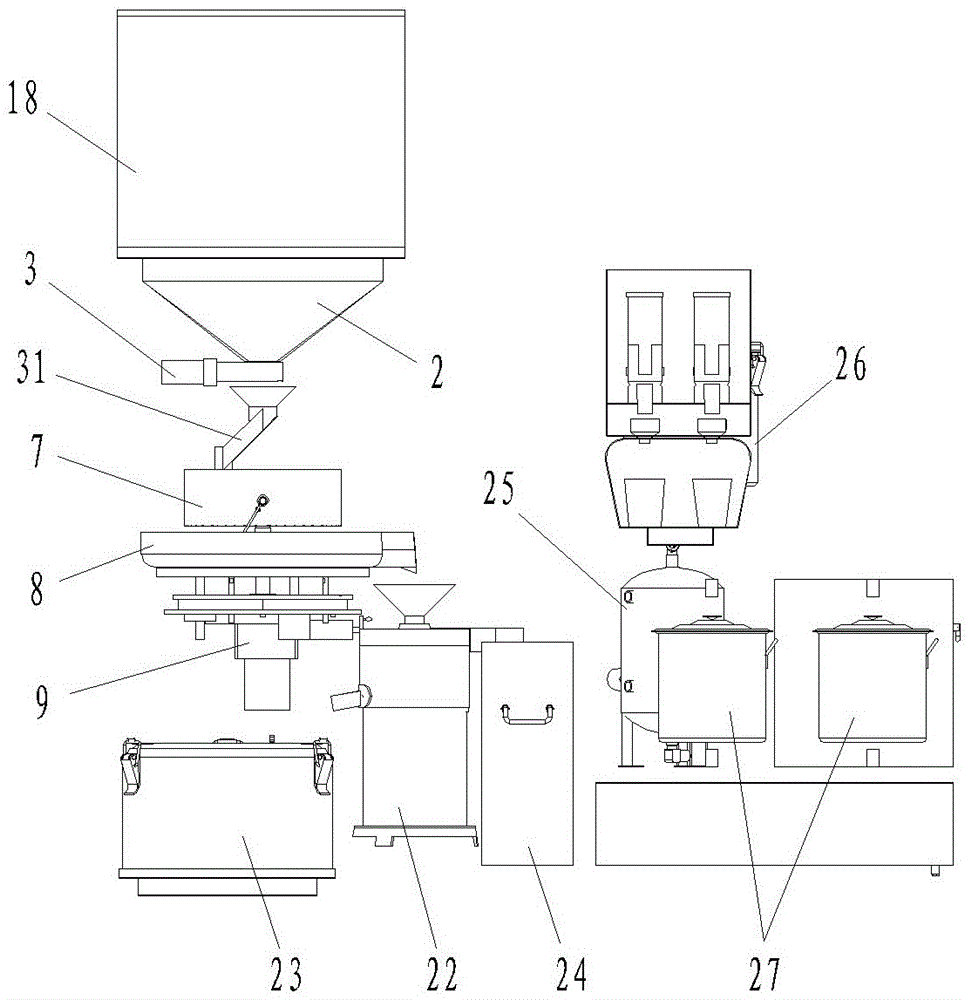

[0032] See attached figure 1 , 2 And 8, the present invention provides a kind of full-automatic stone-milled soymilk machine, comprising casing 1, the pulping system that is arranged on the inner frame of casing 1, pulping system and supporting control circuit, the key lies in: above-mentioned pulping The system includes a feeding device and a stone grinding device. The feeding device includes a hopper 2 and a quantitative feeding device 3. The end of the hopper 2 is conical and communicates with the inlet of the quantitative feeding device 3. In the hopper 2 A material shifting mechanism is arranged inside the tapered end, and the material shifting mechanism includes a shifting motor 4 , an extension shaft 5 fixed to the output shaft of the shifting motor 4 , and a shifting plate 6 fixed on the extension shaft 5 .

[0033] When the stone mill grinds soybean milk, the dosing device 3 supplies soybeans to the stone mill, and the dial plate 6 rotates around the extension shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com