Method for preparing CMC/GO compound hydrogel microspheres by virtue of continuous method

A composite hydrogel, continuous process technology, applied in water/sewage treatment, chemical instruments and methods, adsorbed water/sewage treatment, etc. The effect of high quality, good swelling properties and good market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment first prepares CMC / GO composite hydrogel microspheres according to the following steps:

[0038] (1) Preparation of CMC / GO / CA mixed solution

[0039] The graphite oxide prepared by the Hummers method is ultrasonically exfoliated and dispersed in deionized water, and then a certain amount of CMC and CA are dissolved in water respectively, and a mixture of CMC / GO / CA is obtained by solution blending, wherein the content of graphene oxide is 8wt%;

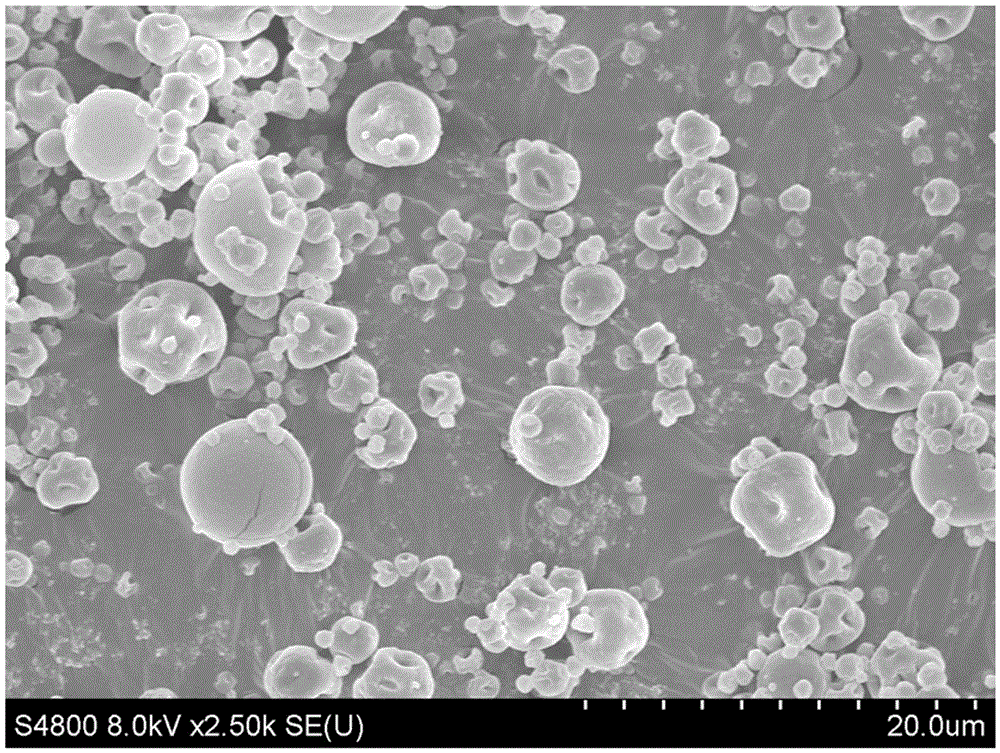

[0040] (2) Preparation of CMC / GO composite hydrogel microspheres by spray drying

[0041] Set the appropriate inlet temperature, injection volume, and air flow rate, and prepare CMC / GO composite hydrogel microspheres through the spray dryer. During the spray drying process, due to the high temperature, the -OH on the crosslinking agent CA and the CMC on the CMC The -COOH undergoes an esterification reaction;

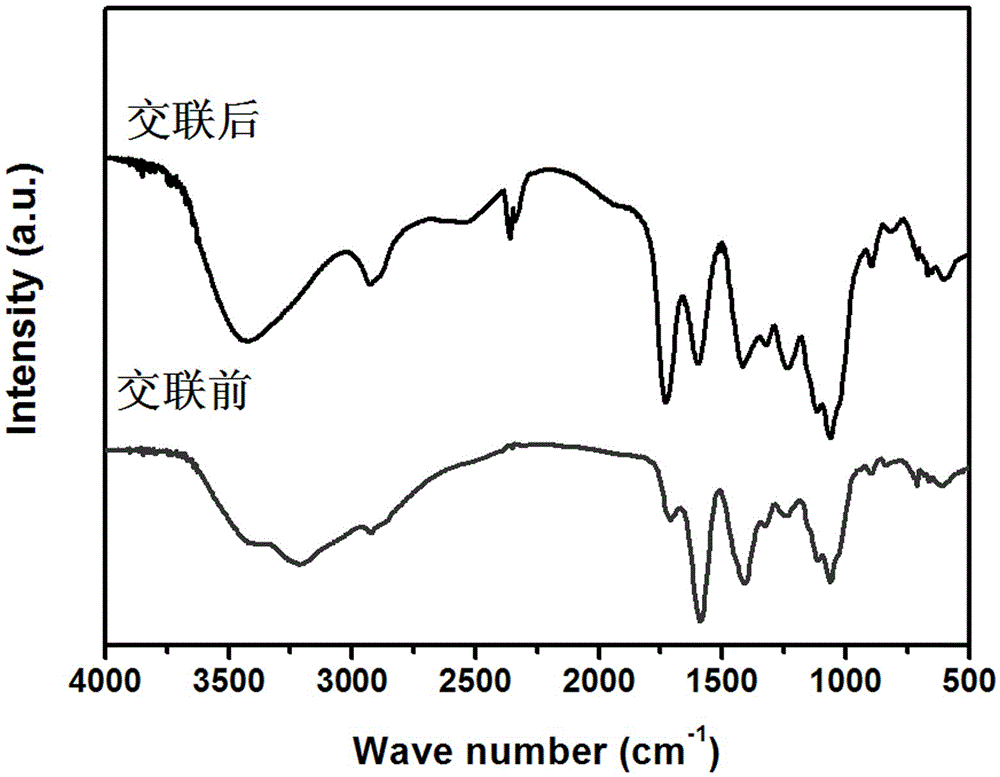

[0042] figure 1 Infrared (FT-IR) spectra before and after crosslinking of CMC / GO composite hydrogel ...

Embodiment 2

[0046] This Example 2 prepares CMC / GO composite hydrogel microspheres in the same manner as in Example 1, the difference is only the 2wt% of graphene oxide in step 1.

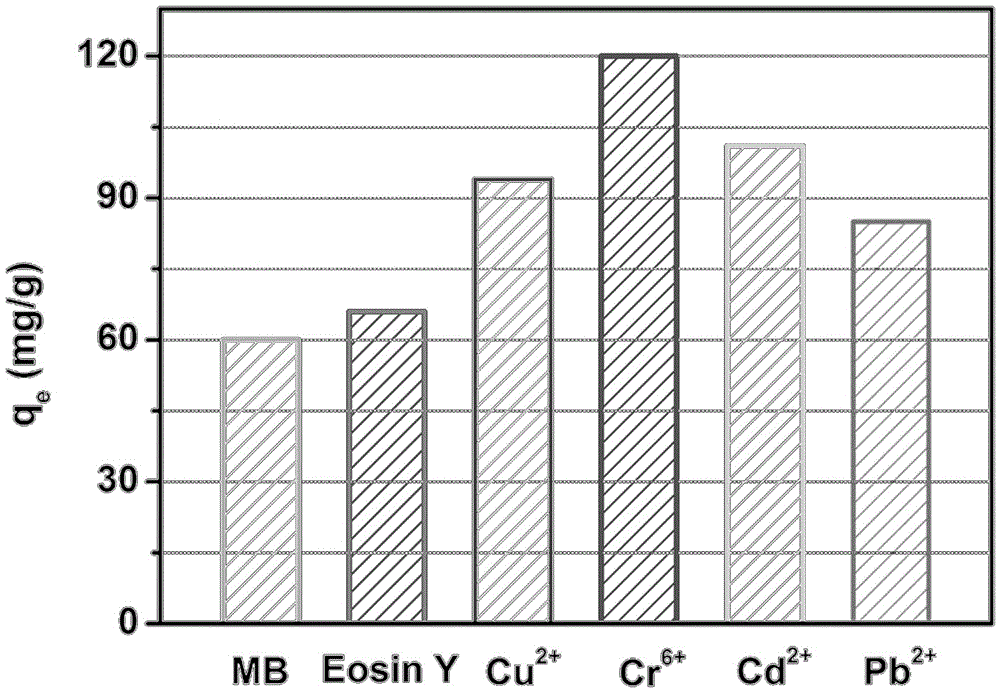

[0047] After testing, the CMC / GO composite hydrogel microspheres obtained in this example have no effect on the metal ion Cu 2+ 、Cr 6+ 、Cd 2+ , Pb 2+ The adsorption amounts of the organic dyes MB and EosinY were 38mg / g, 45mg / g, 41mg / g, and 37mg / g, respectively.

Embodiment 3

[0049] The present embodiment 3 prepares CMC composite hydrogel microspheres in the same manner as in embodiment 1, the difference is only the 4wt% of graphene oxide in step 1.

[0050] After testing, the CMC / GO composite hydrogel microspheres obtained in this example have no effect on the metal ion Cu 2+ 、Cr 6+ 、Cd 2+ , Pb 2+ The adsorption capacity of each is 59mg / g, 76mg / g, 59mg / g and 49mg / g. The adsorption amounts of organic dyes MB and EosinY were 39mg / g and 41mg / g, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap