Clamping device for precisely machining inner surface of conformal optical cowling

A clamping device and precision machining technology, which is applied in the direction of clamping device, positioning device, metal processing equipment, etc., can solve the problems that it is difficult to completely fix the fairing, the total deformation is unpredictable, and the processing accuracy is difficult to guarantee. The effect of high precision, improving processing accuracy, ensuring processing accuracy and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

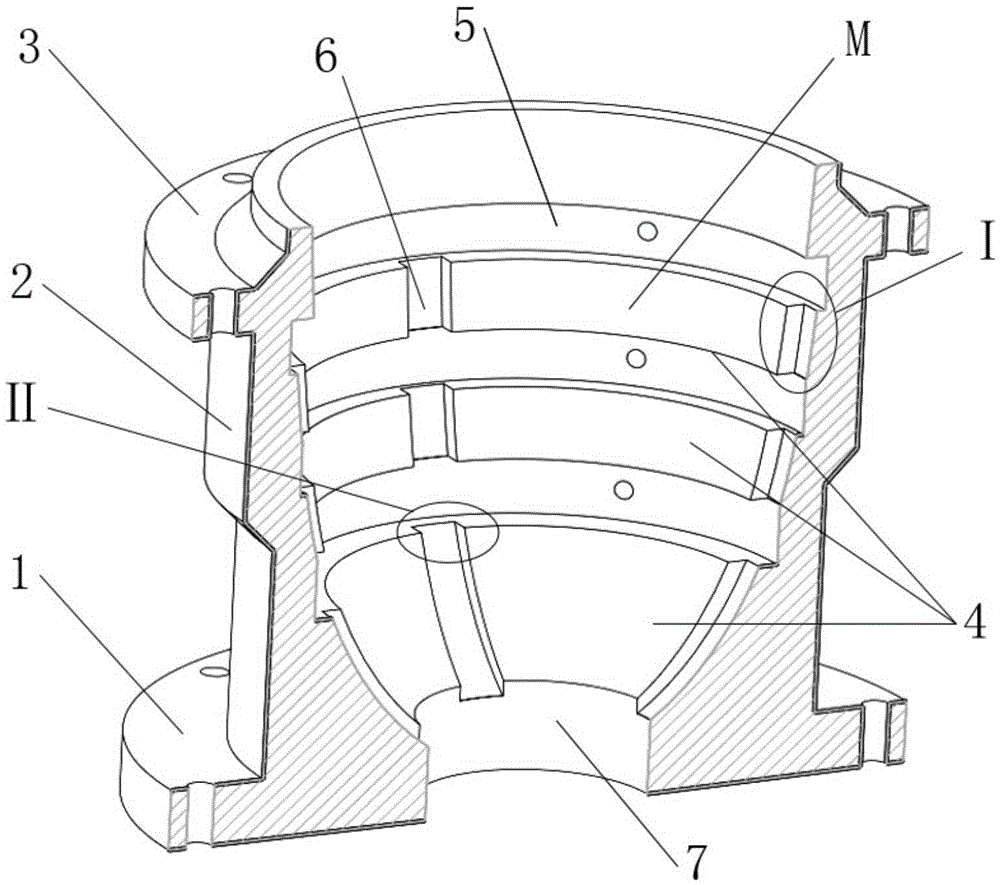

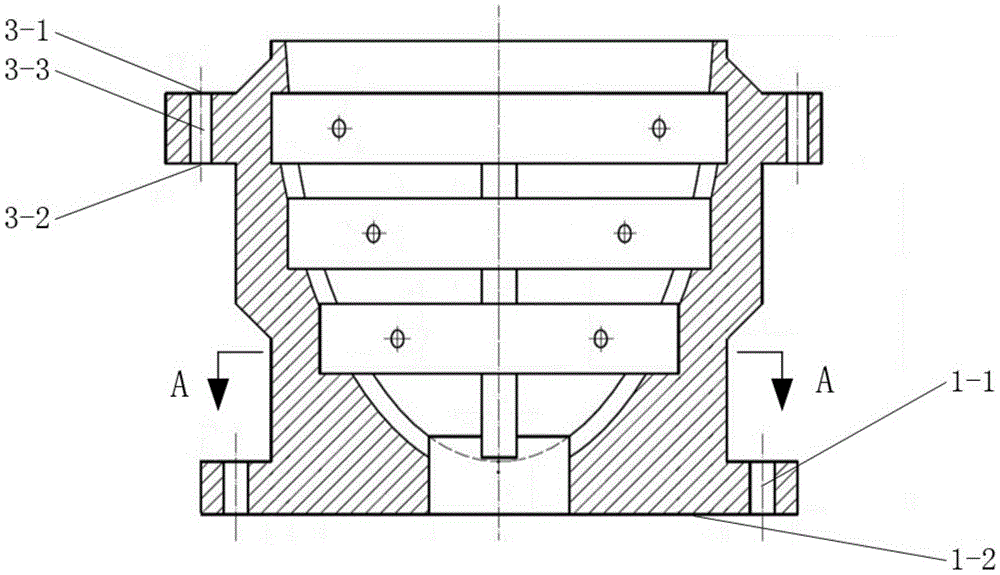

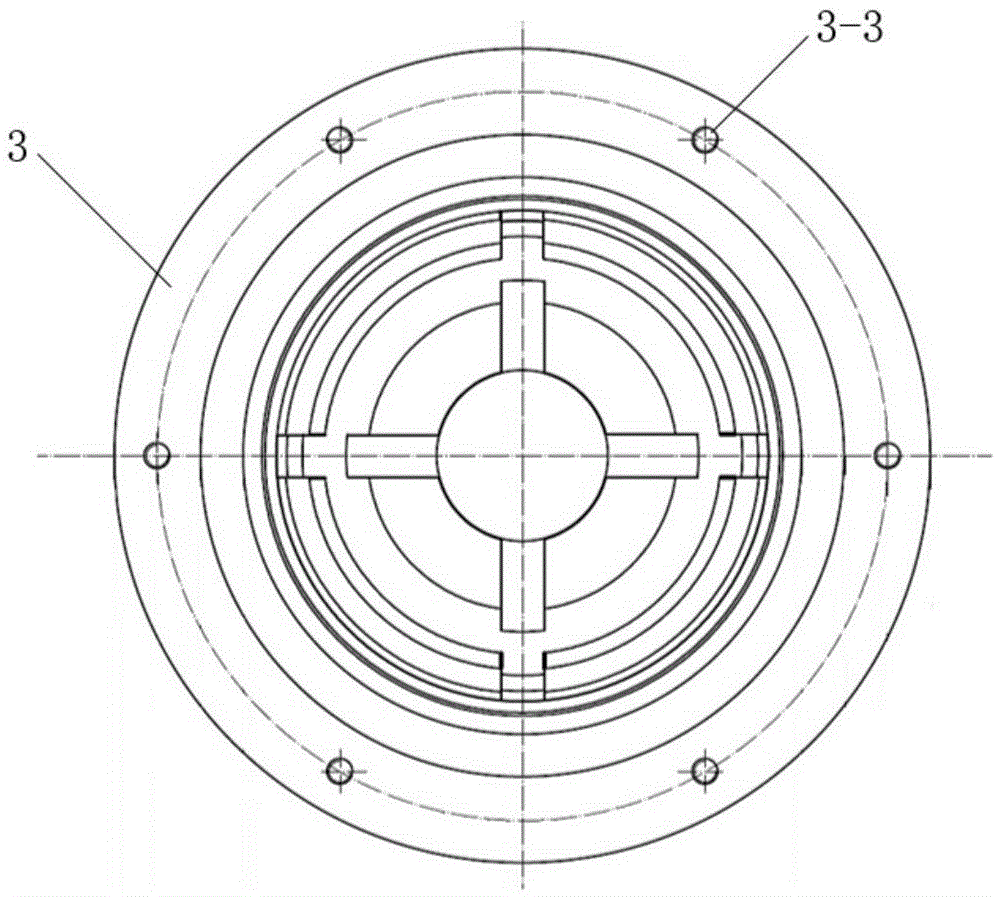

[0018] Specific implementation mode one: combine Figure 1 to Figure 6 Describe this embodiment, this embodiment includes a base body 2, the upper end of the base body 2 is provided with a flange 3, the lower end of the base body 2 is provided with a base 1, the inner cavity of the base body 2 is a curved surface cavity M, and the curved surface cavity The cross-section of M is a variable section that gradually decreases from top to bottom. Several annular positioning bosses 4 are arranged on the inner wall of the curved surface cavity M. Consistent, there are transverse grooves 5 between adjacent two annular positioning bosses 4, longitudinal grooves 6 are provided on several annular positioning bosses 4, and the center of the bottom of the base body 2 is provided with a curved inner cavity M Interlinked through holes 7 avoid positioning errors caused by size errors and surface shape errors at the top of the fairing, and the diameter and height of the through holes 7 determin...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination Figure 5 To describe this embodiment, the height h of the annular positioning boss 4 in this embodiment is 20 mm to 100 mm, and the thickness s of the annular positioning boss 4 is 3 mm to 50 mm. The size of the annular positioning boss 4 is an important factor affecting the total deformation of the fairing and the local stress concentration, and should be designed through theoretical analysis and simulation calculation. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0020] Specific implementation mode three: combination Figure 5 To describe this embodiment, the height h of the annular positioning boss 4 in this embodiment is 50mm, and the thickness s of the annular positioning boss 4 is 10mm. The size of the annular positioning boss 4 is an important factor affecting the total deformation of the fairing and the local stress concentration, and should be designed through theoretical analysis and simulation calculation. Other components and connections are the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com